Home =

powder handling - search results

If you're not happy with the results, please do another search

Volkmann GmbH on the concept of closed circuit in powder handling for 3D-printed parts

As you may already know, once they pop out of the 3D printer, 3D printed parts must undergo some sort of post-processing (such as removing supports, tumbling, sandblasting, CNC milling, chemical dips or even...

Russell Finex introduces a new powder handling solution for metal 3D-printed parts

Russel Finex, a company that specializes in the design and manufacture of vibratory sieves, separators, ultrasonic mesh debinding systems and liquid filters, has introduced an upgraded version of its powder handling solution.

Called AMPro® Sieve...

Join AMP+ webinar on automated powder handling in the SLM process

AMP+, short for AM Powder Plus, will run a webinar on automated part and powder handling in the Selective Laser Melting process on July 08th from 15-16 p.m. CET.

Headlined “Automated depowdering of parts and...

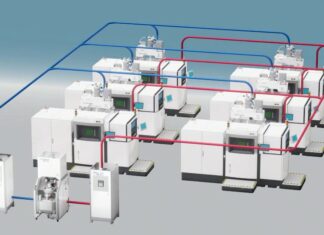

AM Powder Plus (AMP+): A network that enables efficient parts and powder handling in additive manufacturing

Assonic Dorstener Siebtechnik GmbH, Solukon Maschinenbau GmbH and ULT AG, three Germany-based SMEs join forces to address challenges operators faced when it comes to establish AM as an industrial process for serial production.For operators...

assonic develops a 2-in-1 reactive metal powder preparation system for Additive Manufacturing

Machine manufacturer assonic Dorstener Siebtechnik unveils this week at Formnext 2024, a new reactive metal powder preparation system for Additive Manufacturing. The system stands out from the crowd due to its ability to operate...

Stratasys and AM Solutions launch a 3-in-1 post-processing solution for the H350® SAF® powder bed 3D printer

3D printer manufacturer Stratasys joins forces with AM Solutions – 3D post-processing technology, a brand of the Rösler Group, to develop Stratasys PowderEase™ TI, a 3-in-1 post-processing solution designed for the Stratasys H350® SAF® powder bed...

New dimensions of depowdering: The Solukon SFM-AT1500-S

In recent years, vertical industries such as aerospace, where high efficiency drives the way components are manufactured, have continuously pushed the boundaries of what is possible with Additive Manufacturing. At the same time, some 3D...

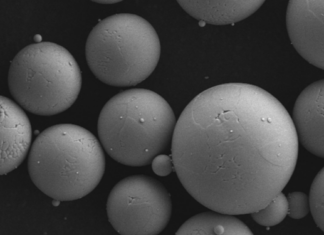

Tekna introduces advanced Ti64 coarse powders for L-PBF printing

Tekna, a producer of advanced materials, has launched the Ti64 coarse powders for (Laser Powder Bed Fusion) L-PBF printing. Tekna's Ti64 powders are developed with the company’s proprietary plasma atomization technology, which makes them...

Rodhe & Schwarz deploys automated depowdering solution from Solukon

Rohde & Schwarz has been in the field of mechanical and electronic assemblies for the past 90 years. It has a production plant at Teisnach, Bavarian where its Additive Manufacturing division produces heat exchangers,...

Key considerations to take into account for depowdering of plastic 3D printed parts.

Among the post-processing tasks that have often been considered modest priorities by OEMs, there is depowdering. The thing is, a lot of consideration has always been given to depowdering of metal 3D printed parts,...