Home =

Automated depowdering - search results

If you're not happy with the results, please do another search

M&H bets on a Solukon system for depowdering of metal 3D printed parts

M&H, a provider of design, 3D metal printing, surface treatment and finishing services, has added an automated depowdering system to its production environment. The Austrian company wanted to ensure the metal 3D printed parts...

Key considerations to take into account for depowdering of plastic 3D printed parts.

Among the post-processing tasks that have often been considered modest priorities by OEMs, there is depowdering. The thing is, a lot of consideration has always been given to depowdering of metal 3D printed parts,...

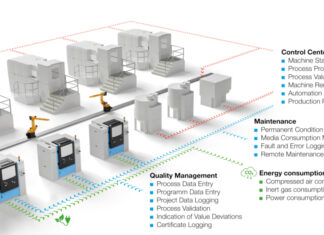

Solukon’s upgraded Digital-Factory-Tool can now measure the carbon footprint of depowdering

Germany-based automated depowdering company Solukon is enhancing its two-and-a-half-year-old Digital Factory Tool (DFT) with a carbon footprint measuring solution.

To fulfill its role in comprehensive quality monitoring and the digital integration of the machines, Solukon...

Solukon adds three key upgrades to its depowdering system for metal 3D printed parts

Two years ago, we caught up with Andreas Hartmann, CEO and CTO of Solukon to discuss the SFM-AT350, the company’s depowdering system for medium-sized metal 3D printed parts. Today, the company unveils an upgraded version...

Solukon and Rivelin to put forward automated solutions for the Additive Manufacturing industry at Formnext 2023

The German machine manufacturing company Solukon and British robotics technology company Rivelin have completed an R&D project regarding the applications of their products in easing the Additive Manufacturing process, and the results of this...

Solukon releases a powder collection unit that should be used after the depowdering of metal 3D printed parts

With every step that surrounds the depowdering process, machine manufacturer Solukon is uniquely positioned to address the challenges of the main steps that precede or follow the depowdering phase. One of these challenges consists...

The medical 3D printing market keeps growing. How do the latest advancements in depowdering fit into this evolution?

A couple of years ago, I took part in a MedTech conference in Eindhoven (The Netherlands) where I accidentally stumbled upon a book that read: "modern medicine was no accident, except when it was....

Solukon and Reichenbacher Hamuel GmbH automate unpacking and depowdering of 3D printed parts in a single system

A collaboration with Reichenbacher Hamuel GmbH, a manufacturer of CNC machining centers, led depwodering expert Solukon to further improve the removal of unfused powder for metal 3D printed parts. Together, both companies have been...

New upgrade enables Solukon to enhance depowdering of metal 3D printed parts for SLM Solutions

Solukon has integrated an optimized swivel arm into its SFM-AT1000-S automated depowdering system. Designed for large parts, the automated depowdering system can process parts as big as rocket engines and combustion chambers. Solukon has...

Solukon’s SPR-Pathfinder® Software to Bring Depowdering of 3D Printed Parts to the Next Level

The development and improvement of depowdering solutions is not solely based on machines. A key part of their functionality and their ability to achieve an automated and repeatable work is based on the software...