“As additive manufacturing technology continues to evolve, so too will software solutions from companies. Taking advantage of real-time production data alongside machine learning algorithms to obtain accurate insight into a specific manufacturing process might still seem a distant concept for some companies — but not for AMFG’s customers.”

Keyvan Karimi, CEO of AMFG, is our guest in this Opinion of the Week. Unlike other Opinions of the Week, Keyvan will not discuss any specific topic today. By revealing the contribution of the company so far, he also reminds a striking point: the journey towards industrialization is not a solitary one.

Based on your customers’ feedback, and speaking of software, what are the issues encountered by companies that want to take advantage of AM technologies?

The main challenge we see is that traditional software packages are disconnected. In other words, they lack consistency and traceability. As a result, the production process is slow and very time-consuming…hence the need to automate it.

The main challenge we see is that traditional software packages are disconnected. In other words, they lack consistency and traceability. As a result, the production process is slow and very time-consuming…hence the need to automate it.Our software is a single platform that integrates different modules. How it is integrated into a customer’s workflow depends on the needs of the customer. Before integrating our product into a customer’s workflow, we first need to understand their business and how they intend to operate and scale in the future. Based on their needs, we identify the modules that best meet each process: manufacturing process, operational process, etc.

A customer that does end-part production, for instance, will have a different need from one who wants to use our software to manage their prototyping facility. Therefore, the modules we will supply won’t be exactly the same for both customers. Indeed, end-part production will require good flexibility and repeatability of parts, whereas prototyping requires understanding the high variability of different parts, the different manufacturing requirements and different technologies. The operational process is also very important in this situation, especially if it is a service that is dedicated to prototyping.

So, one of our unique selling points is the flexibility we offer.

What are the main features of your software?

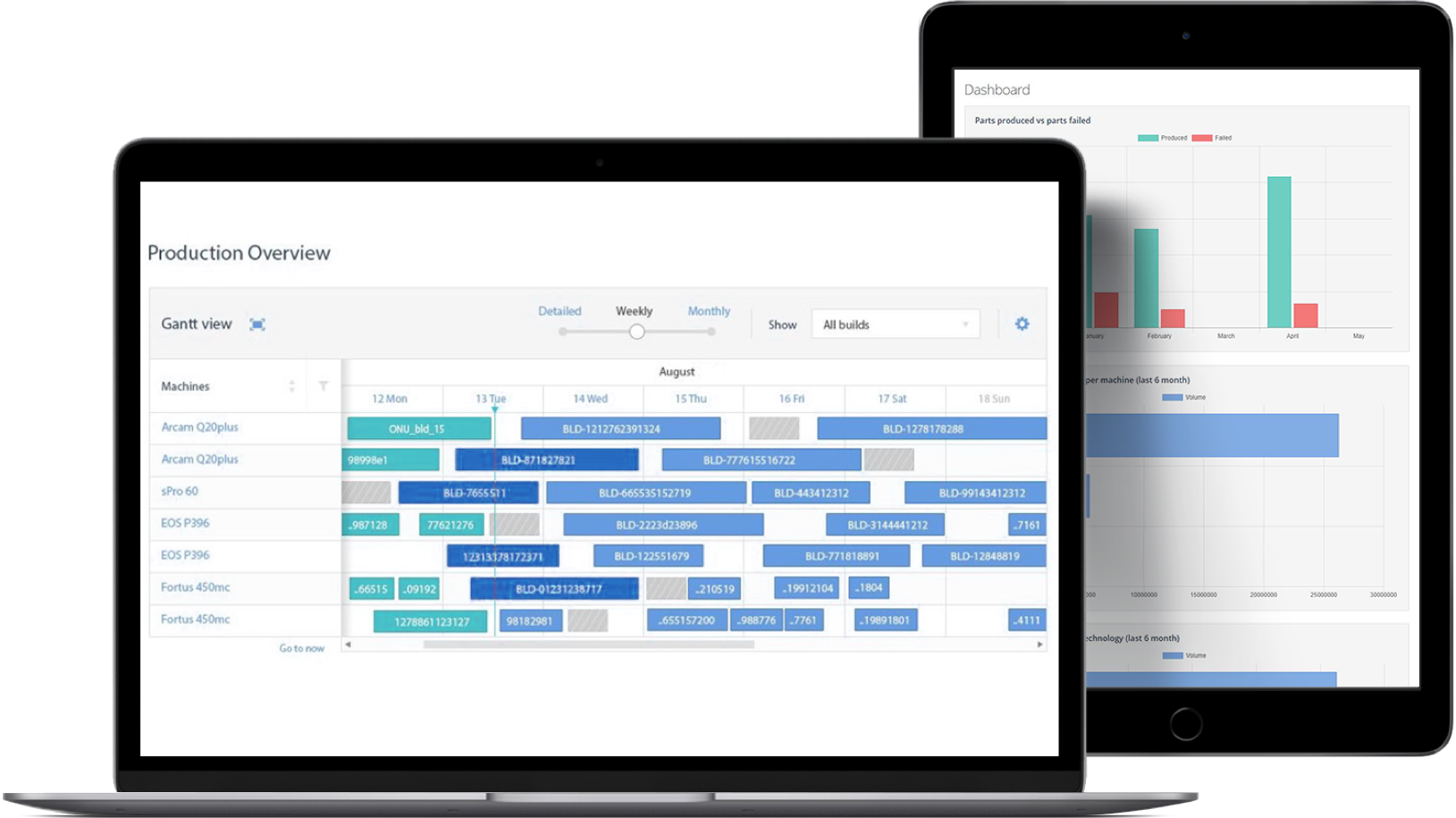

Our software solution connects and automates the manufacturing process. It enables the customer to save time during the production and it ensures quality control of the process and flexibility. So broadly speaking, we have modules that standardise the request management process, and streamline the production management and scheduling as well as post-processing management.

Our software solution connects and automates the manufacturing process. It enables the customer to save time during the production and it ensures quality control of the process and flexibility. So broadly speaking, we have modules that standardise the request management process, and streamline the production management and scheduling as well as post-processing management.Simply put, our product only targets professional users, since we’re solving a volume problem in the market. If the volume of a customer is just 100 parts, for example, then he will not really need AMFG’s software. However, if a customer aims to scale up AM and wants to achieve bigger production volumes, our product will certainly bring great value. Our customers usually produce between 10 000 and a few million parts annually.

Is it compatible with all AM technologies?

We have technical integrations with a range of machines. Our product is generally used across both plastic and metal markets as well as silicone 3D printing, and we have a range of customers that come from different sectors. However, in terms of benefits, we realize that the volumes are much higher in the polymer 3D printing market.

We have technical integrations with a range of machines. Our product is generally used across both plastic and metal markets as well as silicone 3D printing, and we have a range of customers that come from different sectors. However, in terms of benefits, we realize that the volumes are much higher in the polymer 3D printing market.

What type of partners can you have in this industry and for which purpose?

As far as technology partners are concerned, we mainly work with software companies and hardware companies.

Our product is “a horizontal solution” and we can’t always solve issues internally. Collaboration with other software companies enables us to address issues we can’t address internally. – As a reminder, AMFG has recently partnered with LEO Lane. This partnership has enabled AMFG to improve its MES system by integrating LEO Lane’s security solutions to its offering. On the other hand, LEO Lane has integrated AMFG’s workflow management solutions into its customers’ manufacturing processes. ––

As for hardware companies, we work with companies that already use our product in order to improve it in their workflow.

You have recently opened an office in Germany. Do you have any other plans for expansion?

Germany is indeed a key market for us. Aside from that, we have offices in the UK, Eastern Europe and we aim to expand gradually globally. We also have a large database of customers in the US so our next location would probably be North America.

Your last word?

I will recommend any company that aims at scaling up AM to look at automation. Automation can really leverage the benefits of AM.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter! Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com