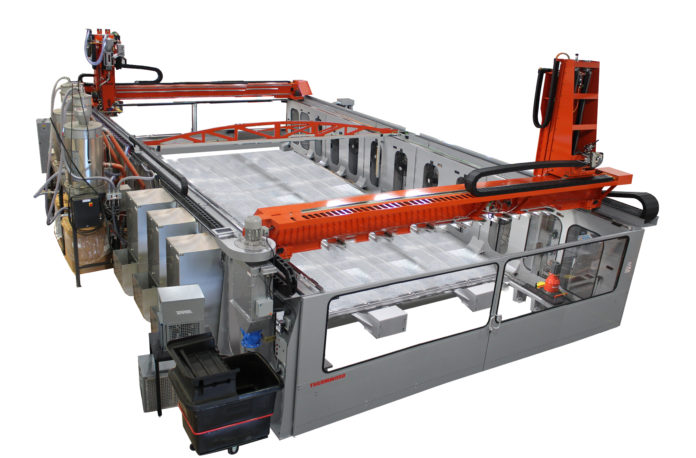

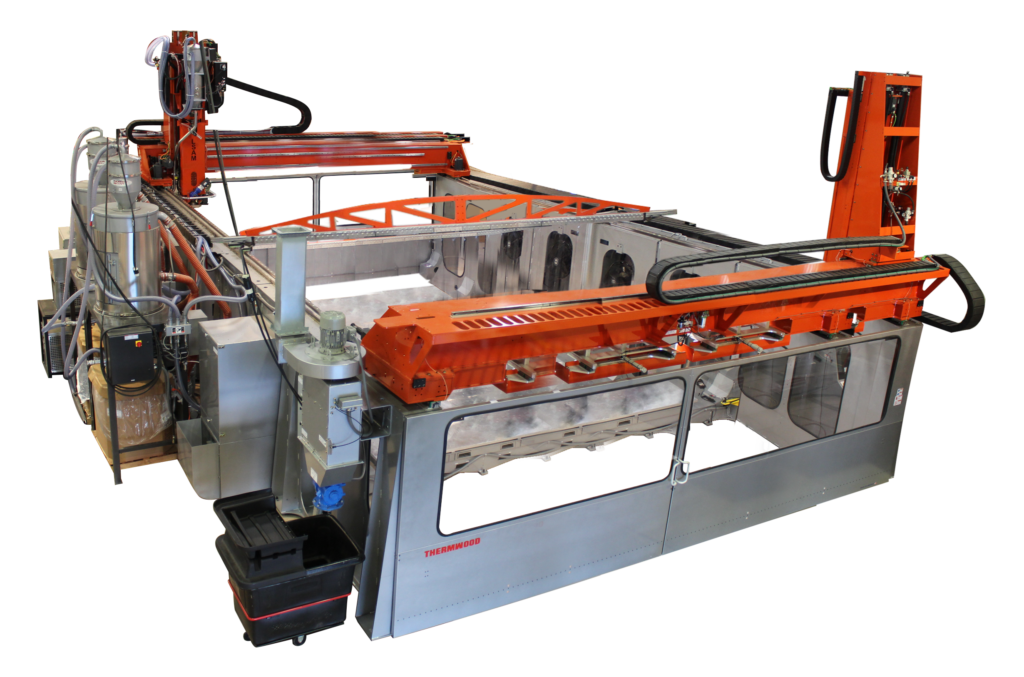

Following the recent launch of the smaller LSAM Additive Printers, Thermwood further expands its portfolio with large table flagship LSAMs. This time, the US-based manufacturer of large-scale additive manufacturing machines has developed various models that range from 5×5 foot to 15 foot width tables (1,5m x 1,5m to 4,5m x 4,5m).

Just like the ten-foot (3m) wide tables, the new fifteen-foot wide table machines are available in lengths from twenty foot on (6m), in ten-foot increments.

In addition to the width that makes the new 3D printers outstanding, operators can benefit either from a 40mm or 60mm print core. The main difference between the two types of print core is that the40mm core can process most polymers at about 200 pounds per hour (91kg/h) whereas the 60mm core can print at more than 500 pounds per hour (227 kg/h).

Apart from these two items, the new machines can integrate most features that are found in other machines from the manufacturer. This means that, the company’s patented Vertical Layer Print system can be embedded into the machines – which would enable the printing of parts up to fifteen foot (1,5m) wide and as tall as the length of the table -. It also means that the machines feature the new heavier gantry design, the same powerful features such as the thermal sensor layer automation system and they come with three print head options.

As a reminder, the new heavier gantry design was developed for the LSAM 1010. With a weight of over 7,000 pounds (3175 kg), resulting in a live load (the parts of the machine that actually move) of over 18,000 pounds (8165 kg), the LSAM 1010 can move at speeds up to almost three feet per second (91 cm/s).

In this specific case, Thermwood explains that the smallest table length available in the fifteen foot width LSAM is twenty foot (6m). However, due to the modular design of the table and support walls, this length can be increased by ten-foot (3m) increments.

“The most popular table lengths to date for the ten-foot (3m) wide table LSAM machines have been twenty foot (6m) and forty foot (12m)”, one reads.

Speaking of the print head options, they are available for machines which can achieve maximum print rates of 100, 200 and over 500 pounds per hour (45, 91, 227kg per hour).

“Although many believe that print rate determines how fast a layer can be printed, it is actually polymer cooling that determines how much time is needed between layers. Print head output then determines how much bead can be printed in that time and thus how large a part that can be printed by that print head using that polymer. The Thermwood LSAM 60mm print head with 500 pound (227kg) per hour maximum print rate can print the largest part layers possible today”, Thermwood clarifies in a press communication.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com