Over time, in the medicine field, we increasingly observe companies dedicate a part or their complete activity to solutions that meet the increasing demand of 3D printed prosthetics.

During the last months for instance, we heard about Hailey Dawson, 7 years old, who opened Game 4 of the World Series, pitching with her 3D printed prosthetic hand. During the Breast Cancer Awareness Month, iMedTech, a South-African based company 3D printed 1000 prosthetic breasts for mastectomy patients, an initiative which enabled these women to gain confidence and self-esteem. Somewhere in the USA, Unlimited Tomorrow provides amputees with 3D printed prosthetics made with the help of Stratasys’ 3D printing systems. In the industry, brands even decided to turn the concept into a game. That’s the case of the insurer Allianz and co-creation platform Launch Forth which recently launched a design challenge aiming at having ideas for 3D printed prosthetics for people with reduced mobility.

Anyway, companies are increasingly implementing actions to bring solutions that will improve the life of people with reduced mobility.

But what fosters this change?

It will be difficult to provide a totally neutral answer since there are many theories on the subject and all of them might be considered.

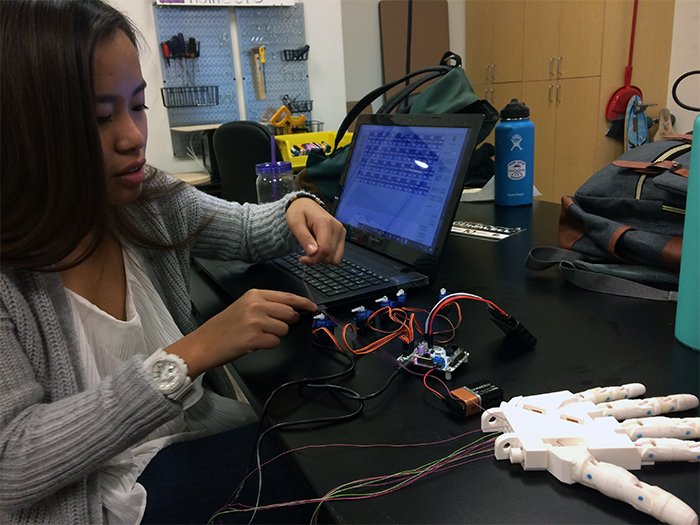

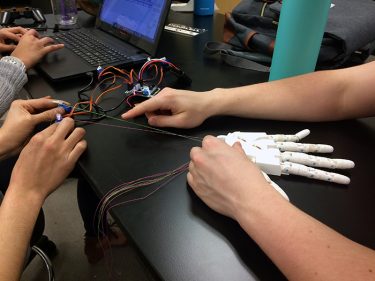

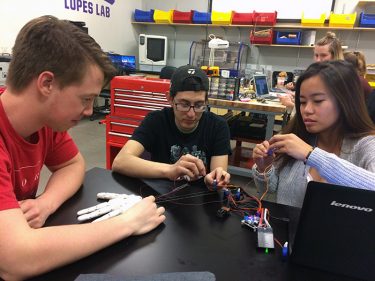

- One of these reasons is the cost. Lana Sweeten-Shults from Grand Canton University (GCU) told the story of a team which made use of 3D printing to provide low-cost 3D printed prosthetics to amputees in Kenya. The students developed a low-cost, 3D-printed hydrocolloidal bandage – an adhesive bandage 2.0, that would aid in treating infections more effectively than a regular bandage or antibiotic creams. The GCU model is carboxymethyl cellulose-based, so it’s made out of a gel-like viscous substance that pulls in bacteria without letting it back out.

buil team GCU – All images via GCU - The quality of the 3D printed prosthetics. In this situation, Gabriela Calhoun, 3D printing biotechnology research team lead explained:

“The positive impact of a hydrocolloidal bandage vs. just a regular adhesive bandage is that it’s 95 percent effective in wound infection prevention, whereas the regular bandage doesn’t have any preventions for wound infections.”

- The accessibility of materials. Be it 3D printing technologies, design or filaments, materials to produce 3D printed prosthetics have increasingly been accessible. TreeD Filaments for instance, a filament producer based in Italy, launched Healthfil, a new range of filaments developed specifically to meet the growing needs of the affordable medical 3D printing segment. In many areas of orthopedics, additive manufacturing represents the newest technological frontier, opening up several new opportunities in terms of product capabilities and accessibility.

- Another reason might be the will to help, to bring its contribution to those in need. 3D printing technology is increasingly evolving and has proven itself in a wide range of areas. So why can we not take advantage of its potential to provide help?

- It would be hard to not mention the corporate social responsibility of companies and their duty to show what they can bring to populations, therefore improve their images and increase their sales.

Anyway, whatever the reason is, it was essential to say thank you to those who think of creating a better world.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});