The Exploration Company, a European spacecraft manufacturer, has decided to rely on Solukon’s technology for the depowdering of its rocket parts. If you’re a regular reader of 3D ADEPT Media, you probably already know that the company is using TRUMPF’s metal 3D printing for the fabrication of core components of the Huracán and Mistral engines – engines that will be integrated to the Nyx Earth and Nyx Moon spacecraft in Planegg near Munich. We first discovered the company’s AM activities through its collaboration with software company LEAP71.

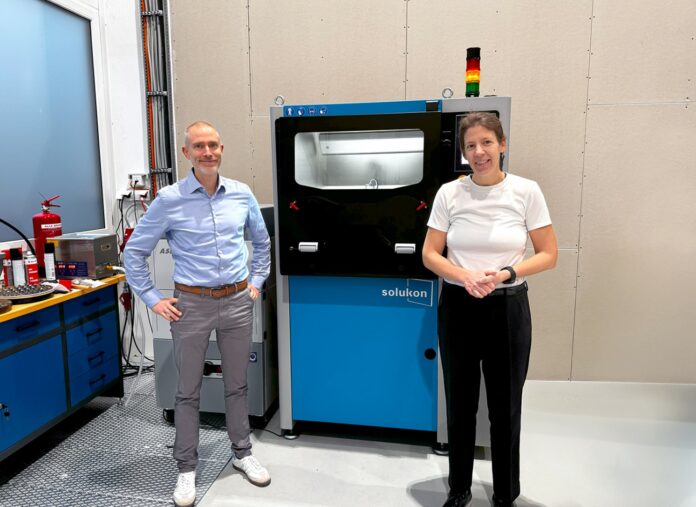

As far as depowdering is concerned, the company opted for the SFM-AT350-E which was unveiled in 2023 for the depowdering of medium-sized parts up to 100 kg. As seen in this test performed in collaboration with the Swiss m4m center, two versions of the machine can be utilized.

The Exploration Company chose an E-version which integrates piezoelectric ultrasonic excitation to clean laser-melted metal parts particularly quickly and gently. According to Solukon, the production of rocket components for the Nyx space capsule requires maximum precision in all production steps. To ensure that everything runs smoothly during the flight of the space capsule, printed components must be completely free of powder.

“With the SPR-Pathfinder software, we calculate in advance how the component must be moved so that all the powder runs out. This enables us to achieve reliable cleaning results and clean components in series,” says Maxi Strixner, Senior Additive Manufacturing Engineer at the Exploration Company. Cleaning can also be pre-simulated with the SPR-Pathfinder. This allows developers to see as early as the design phase whether the component can be completely cleaned or whether the geometry needs to be adapted for better postprocessing.

During the cleaning process in the Solukon system, the powder is collected without contamination and can be reused for further presses after sieving, resulting in significant material savings. In addition, piezoelectric frequency excitation offers the advantage over conventional pneumatic vibrators that significantly less compressed air is required, which enables further savings, Solukon reminds.

This approach fits in perfectly with the Exploration Company’s main maxim: “Our main focus is on the development of reusable space capsules for the transportation of payloads and people into space,” says CEO and founder Hélène Huby.

As you may guess, Solukon’s capabilities have a proven record in the space industry. We just hope the Exploration Company could share some of the wonders they will achieve with this system.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.