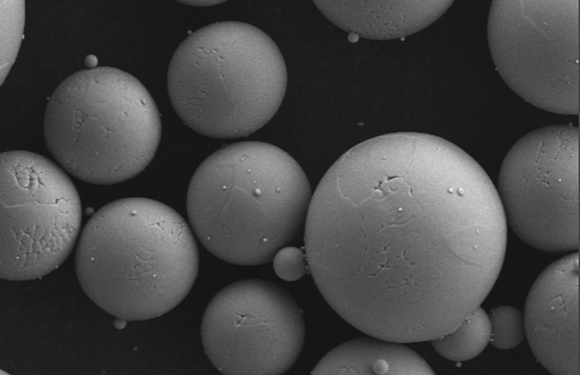

Tekna, a producer of advanced materials, has launched the Ti64 coarse powders for (Laser Powder Bed Fusion) L-PBF printing. Tekna’s Ti64 powders are developed with the company’s proprietary plasma atomization technology, which makes them spherical & extremely dense for improved flowability.

Optimized for printing usage with varying layers of thickness like 60 µm & 90 µm, powder processing leads to an end-user production yield & part reliability. Furthermore, Tekna explains that based on recent qualifications performed on well-known printing platforms, the productivity for a given part increased from 123 cm³/hr at a 60 µm layer thickness to 254 cm³/hr at a 90 µm layer thickness.

Printing thicker layers provides better energy dissipation, which contributes to fewer deformations. This reduces the number and complexity of part supports required during printing. It therefore contributes to decreased post-processing time and costs.

Also, the ability of the users to procure Ti64 coarse powders at fine L-PBF size fractions created from the same plasma atomizers pushes the industrial qualification process even faster.

In safety concerns, finer powders available in LPB-F applications are deemed highly flammable objects. Meanwhile, the coarse Ti64 powders from Tekna are less sensitive to oxygen and static electricity when compared to traditional fine powders which reduces the chances of powder handling, recycling process, and storage & transportation costs.

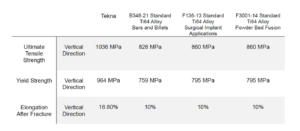

Industry-wise, Tekna’s Ti64 powders features comply with the ASTM standards – B348-21, F136-13 & F3001-14 underscores the overall quality & reliability of the manufactured parts. This would ensure the most critical applications in surgical implants, medical devices, and other complex high-performance components.

Here is a brief comparison table between the original range calculated when compared to the parts manufactured using Tekna’s Ti64 coarse powders:

VP of Sales & Marketing at Tekna, Rémy Pontone says “Our commitment to safety is essential, both for users and the environment. Thanks to their reduced reactivity, Ti64 coarse powders are not classified as flammable and are not sensitive to static electricity, making them safer to handle. This also simplifies logistics, allowing easier transportation and compliance with local storage regulations. Ultimately, these advancements reflect our dedication to delivering high-quality products prioritizing safety and efficiency at every stage.”

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.