Every year, ARIS (abbreviation of “Akademische Raumfahrt Initiative Schweiz”) launches innovative aerospace projects for students of Swiss universities.

In November 2020, the organization completed the fabrication of the first supersonic rocket of Switzerland as part of the EULER project. SLS 3D printer manufacturer Sintratec, a sponsor of the project, supported the team with the production of certain 3D printed components. Today, the machine manufacturer shared a similar experience they went through as part of the student project PICCARD.

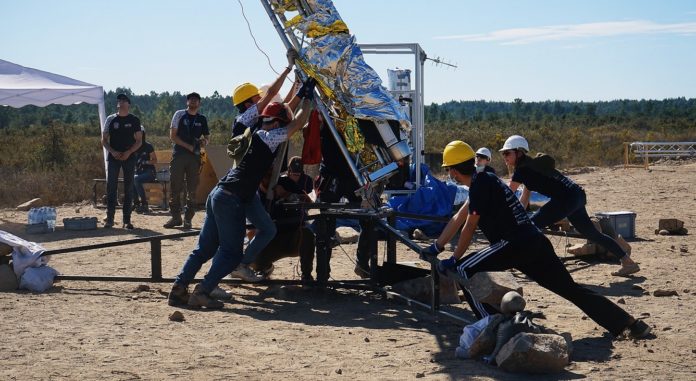

Named after physicist Auguste Piccard, the 2021 project ambitions to build ARIS’ first hybrid-propellant rocket in less than a year, and to win an international rocketry competition. Simulation tests reveal that the hybrid rocket reaches an altitude of over 6 kilometers and set a new world record.

One of the key items that led to this result was the use of various technologies at the manufacturing process, including 3D printing.

Samuel Rütsche, a structural engineer who worked on the project, developed a new coupling mechanism, which is required to combine the rocket’s various segments. Once the rocket is set up and its tank is filled, the filling nozzle is retracted just before launch. «Because we didn’t want there to be a hole in the side of the rocket, I developed a hatch that closes automatically when the filling nozzle is removed», Rütsche explains. This hatch is one of the elements that the students realized with the help of 3D printing technologies.

To quickly develop and test their designs, team PICCARD relied on FDM prototypes. For more demanding structural parts, such as the hatch hinge, Selective Laser Sintering (SLS) was the better solution. «SLS can be used very well in aerospace, because it allows for very light components and for several functions to be integrated into one part», Samuel points out. Sintratec subsequently produced and sponsored the required PA12 nylon parts. According to Samuel, «the material properties of the Sintratec parts are (almost) isotropic and have a better temperature resistance than our FDM printers» – a key benefit when it comes to the extreme conditions in which these parts have to perform.

Once the parts were combined with the hatch, the mechanism worked as planned and provided a smooth rocket fairing during lift-off. «This made sure that our rocket didn’t melt away in the sun and therefore contributed to the successful launch we had in October», Samuel summarizes.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com