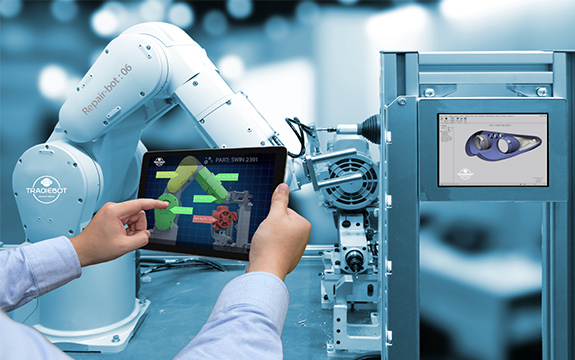

‘Repair Bot’, is an automated repair service that will take advantage of 3D printing technologies and robotics along with complex materials to fix plastic car parts. The collaborative project is launched by Swinburne, Innovative Manufacturing Cooperative Research Centre (IMCRC) and Tradiebot Industries.

This might look like Techniplas Open Innovation Program which aims at gathering various specialists of the 3D printing industry in order to push the automotive industry forward. Detailed explanations can be read in the February issue of the magazine 3D Adept Mag, dedicated to the 3D printing industry (PP-12-13).

A solution to address the issues faced by the automotive repair industry

Repair Bot comes from the need to find technology solutions to issues facing the automotive repair industry. We are precisely referring to material wastage, complex and restrictive design elements and the lack of skilled labour.

The strengths of each partner

In addition to create significant export opportunities and flow-on benefits for the environment by reducing land-fill, the benefits of this project, in Mario Dimovski’s point of view (Tradiebot Industries Founder), will go beyond the automotive collision industry. The company will deliver new skills to the industry since processes increasingly become automated.

Swinburne will bring its R&D team and “problem-solving” skills in the project. This is essential since several aspects of the automated system will include repairs of plastic components.

As for IMCRC CEO and Managing Director David Chuter, he sees in the collaboration, a source of benefits for Australian manufacturers. “This is a unique partnership that explores and invests in advanced manufacturing technologies. It is a great example of how research-led innovation ensures that the Australian automotive repairs industry can meet the challenges and opportunities of the global economy,” he says.

Last, the Tradiebot Repair Bot has already raised over $1.2 million in funding, and research will be carried out throughout 2018 and 2019.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!