Saint-Gobain, a manufacturer of glazing for multiple industrial sectors, has been leveraging 3D printing within its Sekurit business unit in the L'Arboç plant since 2019. The French multinational first appeared in our radar after an investment it made in Continuous Composites. We recently learned that the company has also been an active user of AM.

To enhance the production of automotive parts for its customers, Saint-Gobain has been working with BCN3D’s 3D printing technology, a manufacturing process also used by car manufacturer Nissan to reduce lead times and save costs.

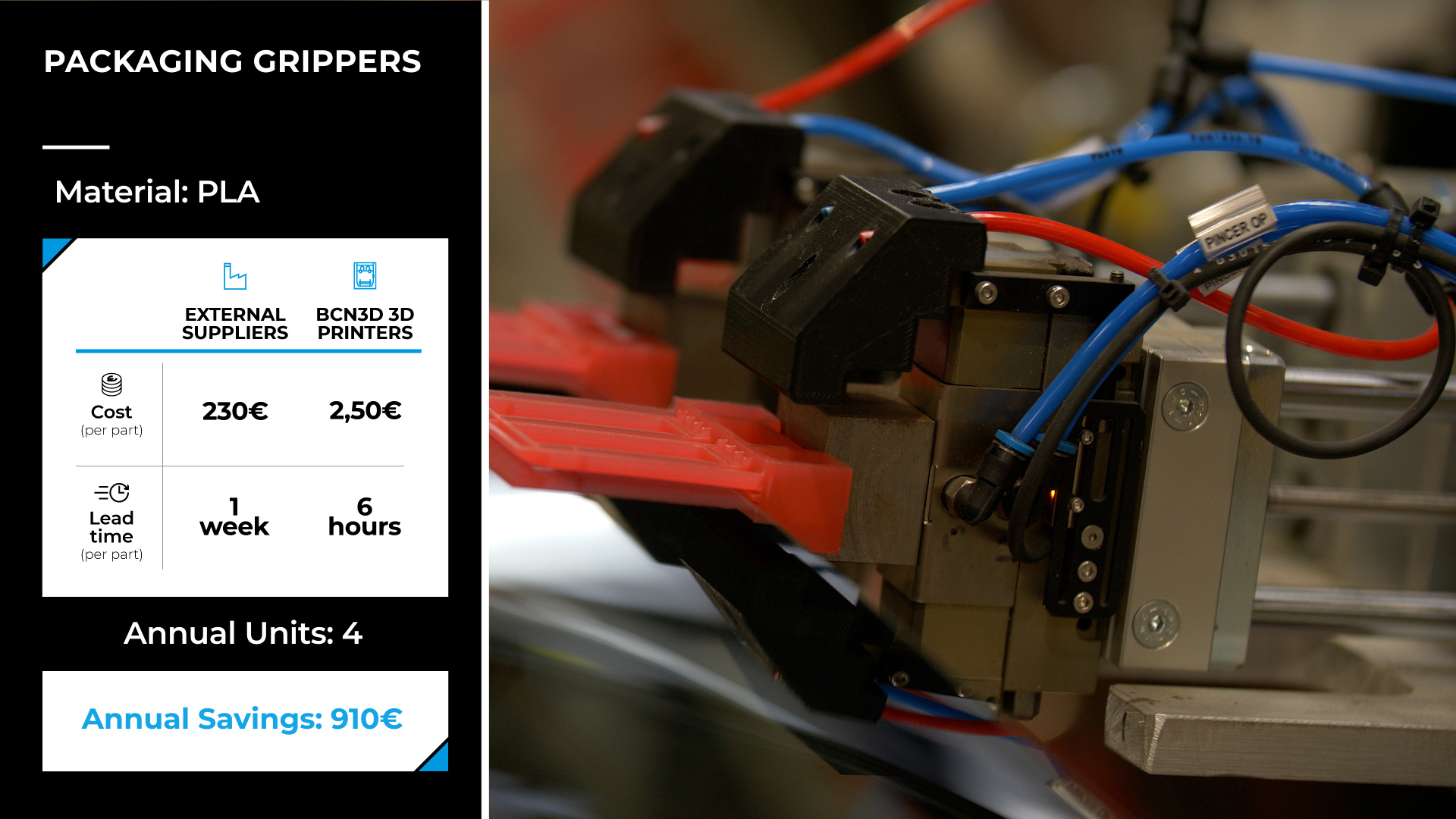

In this specific case, the contract manufacturer fabricates 3D printed tooling with automated lines, that leads to significant improvements in terms of time and costs.

Machine manufacturer BCN3D explains that Saint Gobain integrates additive manufacturing into tooling that facilitates the production of rear and side panels for vehicles. The process begins with a fully automated robot line: the glazing is cut to shape, the sides are smoothed and designated aesthetic details are added. The glazing is then collected and placed in an oven to create the curves. Fresh from the furnace, the glazing is checked for dimensions and quality, and then sorted into pass or fail for manual checking.

To do so, the engineering and operating teams at Saint-Gobain have been using several BCN3D Epsilon W50 series printers and Smart Cabinets ideal for the production of new prototypes.

The incorporation of this additive manufacturing technology has since enabled Saint-Gobain's Spanish plant to save around 170,000 euros and reduce its lead times for tooling by 93%. The 3D printed parts take the form of tools, jigs, and fixtures all the way through to quality control, the company reports.

"At Sekurit we have been manufacturing automotive components for 90 years. Thanks to 3D printing, we have experienced a significant cost reduction and a faster workflow adapted to our needs in the manufacture of tooling and tooling since we incorporated this technology compared to external suppliers we used in the past," explains Angel Salas, Saint-Gobain's maintenance engineer at the Barcelona factory.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com