With over 400+ exhibitors, 200+ conference speakers including 125 educational hours of industry-leading presenters, and 100,000+ attendees, this year’s RAPID + TCT show was a highly anticipated event. With California as a whole being the largest manufacturing producer in the United States, there were a multitude of West Coast small businesses, students, scientists, innovators, makers, and general 3D Printing nerds alike all centered in the City of Angels to learn about the latest technology in the Additive Manufacturing space.

Familiar groups like Women in 3D Printing, Stratasys and the 3D Printing Nerd all hosted fun, rooftop karaoke sessions and happy hours following the first few nights of the conference. There was a noticeable increase in presence from Asian manufacturers as well, given the proximity to Eastern countries for overseas exporting. Additionally, the influence of Hollywood and the film industry was on full display, with a variety of booths and showcases displaying movie props, figurines, and full life-sized prints for recognizable American pop culture references throughout the conference halls.

Faster, smarter more affordable, desktop 3D printers

A decade ago when Netflix launched the 3D printing documentary “Print the Legend”, Desktop 3D printers were thought of as nothing more than an inexpensive means to produce plastic prototypes. Fast forward to 2024, and we now have a large emergence of Desktop 3D printing companies producing quality products for the casual hobbyist all the way up to Fortune 500 Design & Engineering companies – with machines becoming faster, quieter, more affordable, and a wider envelope of material selection.

Companies like Bambu have gained a ton of momentum in more recent years, especially within the maker and retail consumer market. This year, Bambu and a variety of other maker-centric brands with large show presence in heavily-trafficked areas ambition to cater to the masses that were in attendance.

Creality, UltiMaker, Raise3D, and many more FDM (FFF) 3D Printing OEM’s all had their printer heads buzzing in booths showing off just how far servo systems, material science, and print processes are exceedingly fast, efficient and accurate for a low barrier to entry of capital investment for most. Similarly, there were a variety of polymer material companies representing their various types and grades of 3D printing spools and powders.

With the hobbyist 3D Printing companies creating economies of scale, there’s a noticeable uptick in high schools, colleges & universities adopting Additive in their curriculum for Mechanical Engineering, CAD Design, and other Manufacturing-centric areas of study. It’s been great to see more and more students and teachers attend RAPID compared to years past.

Read more on the topic: The “fall and rise” of desktop 3D printing (Jan/Feb edition of 3D ADEPT Mag, PP 12-15)

Volume production Additive Manufacturing (Colibrium)

Bearing the newly branded name, Colibrium Additive (a GE Aviation Company) made its splash for the first time at this year’s show. Shaun Wootton headed up the name change after extensive research and consumer studies: “While the branding is the same, we’re still the disruptor we’ve always been in the space. Being an educator, giving back to universities and educational institutions, and continuing to disrupt the industry. The fundamentals remain the same, our ties to Aviation, advancements in Metal Additive systems, and educator for future generations to come.”

Wootton later went on to explain “Collaboration and Equilibrium” was the inspiration behind this universal branding that was chosen after.

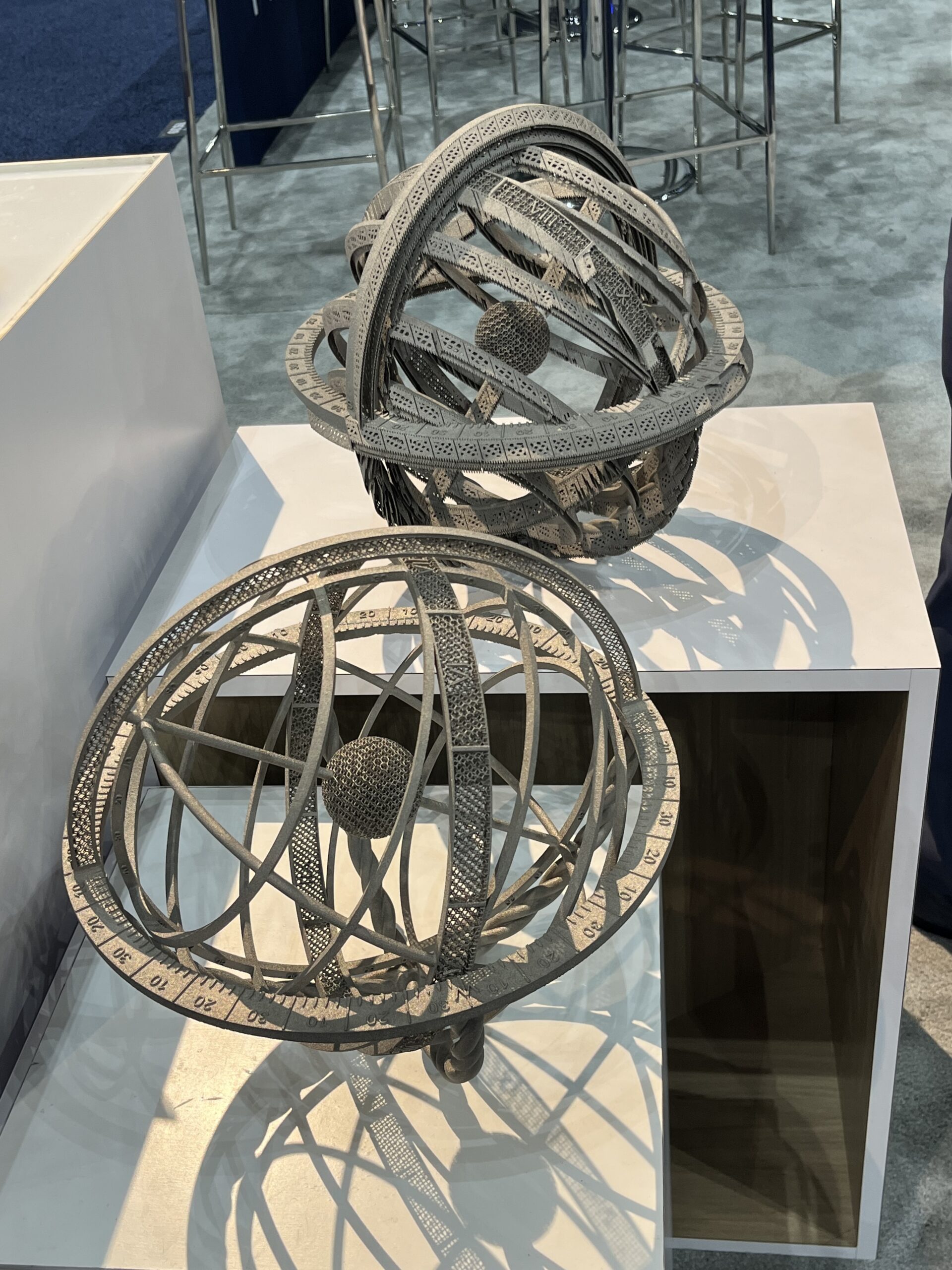

Collibrium had a number of parts on display (as shown above) to showcase their PointMelt technology, which enables things like support-less prints, eliminates the need for a build place, and plots layers with points instead of traditional layer lines. For electron beam melting (EBM) process control, this means a multitude of improvements in quality control, design possibilities, cost efficiency, and more. “With our newer technology, we can manipulate powder size, laser power, layer thickness, infill and others to make for a more efficient print and lower cost run,” Dan Frydryk, Sr Engineering Manager,explains. “By tweaking just the layer size, we can get very detailed with how our prints will perform all by just dialing in or out certain aspects of how we want the part to look.”

The spheres (shown above) are just a small example of the improvements in print speed and quality in more recent years. Now with PointMelt, the need for support is far less than before. Colibrium also showcased their well known Aerospace-certified and medical grade parts (as shown on the left) at the show this year.

Continued expansion of materials (Lithoz)

Ceramic 3D printing was once a far off thought, but is now being brought fruition in the Additive community with advancements in hardware and material technology.

Initially AM was used only with cheaper polymer materials such as PLA, ABS, and ASA. As the technology became widely adopted, came the emergence of Metal 3D printing with powder-bed and laser-sintering technologies. The next giant leap in material science with 3D printing is likely in the realm of being able to additively manufacture high quality ceramic components.

Norbert Gall of Lithoz explains “Ceramics is the next step in the Additive Manufacturing revolution. It offers immense control under extremely hot and cold conditions, while maintaining part resolution and fine features for a variety of applications and component sizes.”

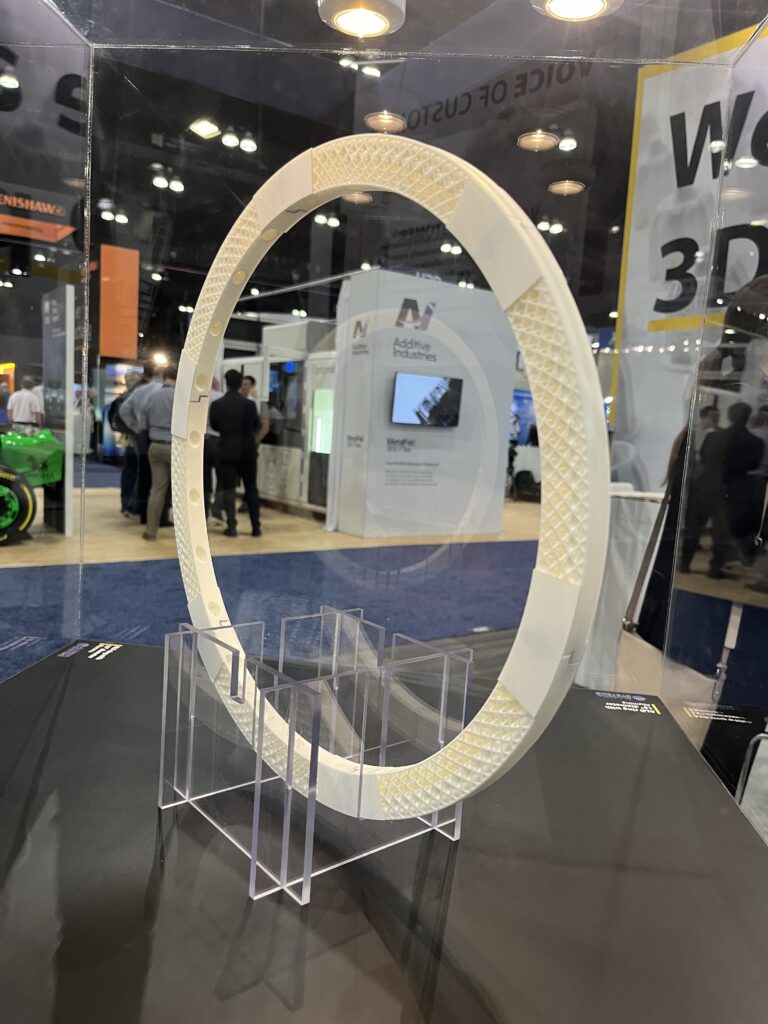

Lithoz showcased a very large, circular part (as shown below) which was all printed in one batch.

“We’re continuing to push the boundaries of what can be done with Ceramic 3D Printing, and are some of the only ones on the market doing it today,” explains Gall. “In addition to handling extreme temperatures, our ceramic chemical makeup also allows for extreme corrosion resistance against a variety of harsh chemicals a given component might encounter in the real world.”

One of the most impressive small parts displayed came towards the end of my time with Gall, which was eye-catching, to say the least. These components represent the breadth and depth of their printers capabilities, and portfolio of applications from in-body medical device parts from aerospace, consumer packaging, and more.

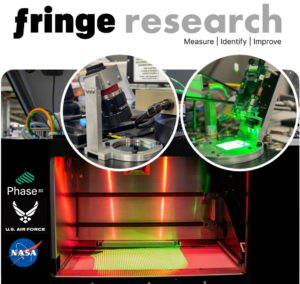

Quality / Traceability (Phase3D)

While it’s been an exciting time to see the Additive Manufacturing community grow up and mature, there’s still a lot of moving parts to consider, especially when it comes to quality control and part traceability. With the recent announcement on fringe research with the Air Force and NASA teams, Noah Mostow of Phase3D believes digitizing quality control is the next logical advancement for taking Additive Manufacturing and part qualification to the next level.

“This year’s RAPID is all about quality. Our system is helping a variety of powder-bed processes by verifying the accuracy of each individual layer all throughout the printing process. This is huge for any manufacturer that’s needing to qualify their parts, but produce detailed reporting of the entire component, layer by layer.” Phase3D demonstrated its In Situ Porosity Prediction Software for Laser Powder Bed Fusion (LPBF) Additive Manufacturing.

Along with Phase3D, there were a variety of hardware & software vendors at the show offering specialized solutions to address QA and QC specifically. Whether it was your 3D scanning, metrology, and measuring equipment, to software-enabled digital tools to automate processing and qualifying parts. Lumafield was another returning exhibitor, showcasing their 3D CT Scanning technology for footwear and a variety of athletic applications.

Increased attention on post-processing capabilities

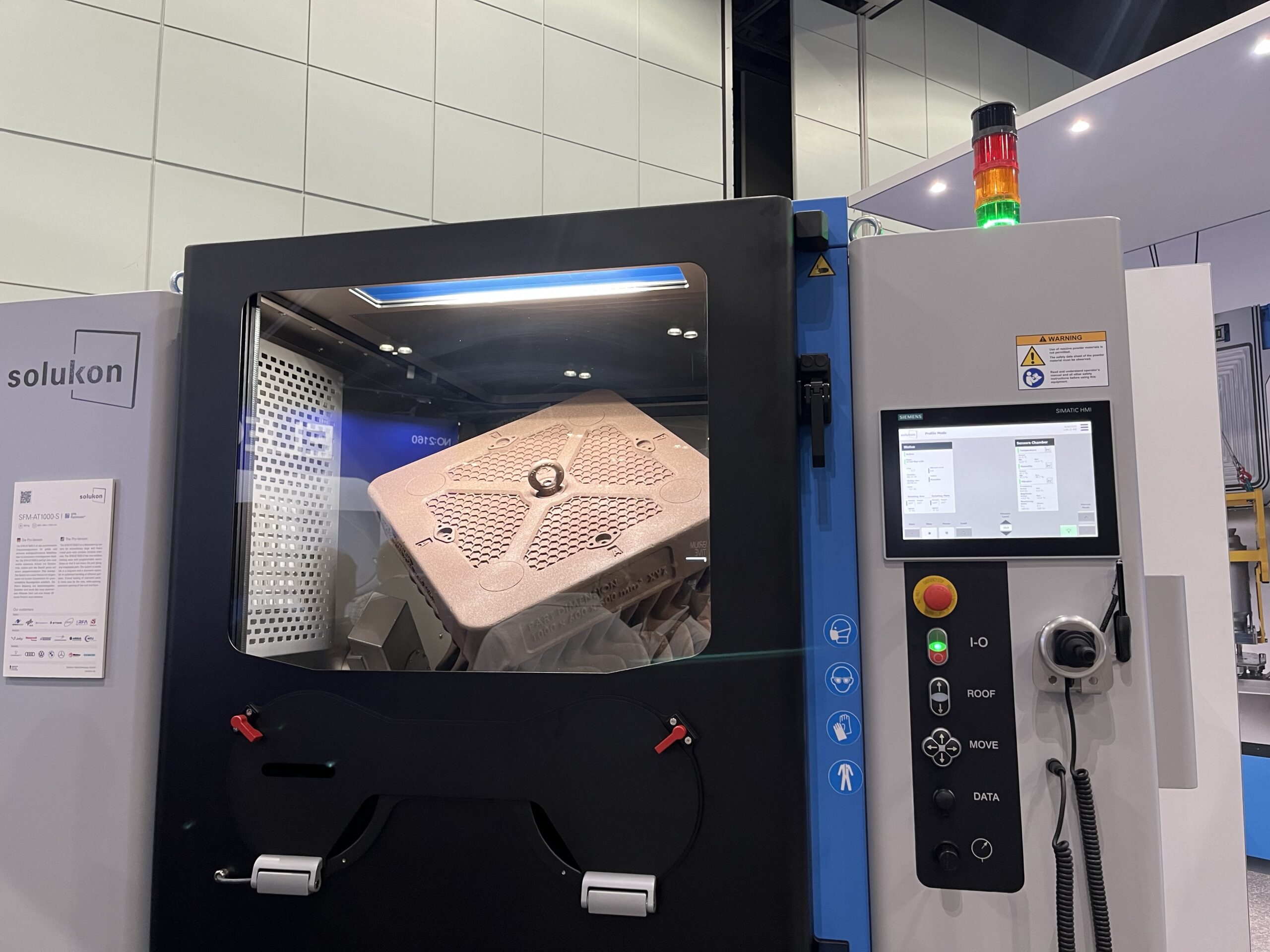

While the dream of AMis simply loading a CAD file and just pressing go, the reality is that there’s often a much needed intervention of post-processing and after-print treatment that’s involved for the majority of 3D prints. Organizationslike Solukon are addressing just that with their automated depowdering systems.

Marina Haugg of Solukon was at the booth this year showcasing the SFM-AT1000-S; a large format automatic depowdering system for parts of up to 1,000mm and 800kg. “While many focus on all of the features & capabilities of the 3D printers themselves, it’s crucial to not forget about the post-secondary operations that are done post-print,” Haugg explains. “Our systems are geared towards OEM’s and end- users in a high-volume production environment and are looking to automate the way they handle metal (and plastic) components once they’re off the print bed.”

For 10 years now, this German-based solutions provider has engineered a variety of systems to work with large, complex, and often hazardous materials for industries that demand highly precise and accurate 3D printed components. These industry-grade systems fair well especially with titanium, nickel alloys, aluminum, and other reactive metals.

Star of the show (nTop + Cobra Golf)

Without a doubt, the busiest attraction and eye-catching demo had to be the metal 3D printed golf irons designed using nTop software in collaboration with San Diego-based Cobra Golf. Ryan Roach of Cobra headed up the design innovation that is taking the golf industry by storm through the help of nTop’s AI-enabled topology optimization design & analysis software.

Allowing for variable wall thickness, hollow internal channels, and complete customization; Roach explained the design thought-process in a keynote presentation on Day 2 of the show. nTop’s CAE software has been utilized in industries beyond golf, spanning heavily into aerospace for heat exchangers, and other commonly 3D printed components for rockets, aviation, and more.

nTop showcased their irons alongside Cobra Golf at the RAPID show the only logical way; by allowing attendees to put them through the test in a series of 3 shots on a golf simulator. As an avid golfer myself, I can attest to the light-weighting aspects of this club, in addition to the cushiony feel of the ball coming off the face of the club. It seemed to be easier to swing, and was more forgiving at times compared to traditional nickel or forced aluminum clubs on the market today.

Aside from the amazing weather, inviting industry celebration events each night, and insightful minds; the 2024 RAPID + TCT show was definitely one to remember. In just a decade’s time, it’s been truly an experience to see 3D printing transform from a novelty rapid prototyping methodology to a full fledged force in the industrial manufacturing economy worldwide. While there is still much room for advancements between hardware and software companies alike, we’re sure to see continued investment and increased attention to this ever growing sector.

Next year’s RAPID is just 10 months away, and will be set in Motor City USA; Detroit, MI with anticipation of various Automotive-centric themes and displays to come. We’re excited for Formnext coming up in November and beyond, see you next year in April for RAPID+TCT 2025.

Read more news on RAPID+TCT 2024 here.

This article has been written by Will Kruspe. Featured image, courtesy of RAPID+TCT 2024, Instagram.