Wood, pellets, resins, powders, filaments…industries can almost 3D print any form of material and the fascinating processes that enable to transform these materials into finished products are also the ones that make the use of appropriate materials so complex. As AM advances, it creates new trends and new complexities that material producers continuously need to unravel. In this series, 3D ADEPT Media asked material producers various questions on different topics that create debate across AM materials users.

3D printing Resins

While the title is not official, it’s simpler to describe the group of machines that work with resin materials as resin 3D printing. There are different types of resin 3D printing processes, each of them having their share of pros and cons. From a manufacturing standpoint, let’s remind that resin 3D printing processes often rely on the principle of photopolymerization; they operate according to a code (or the 3D printer creates a code straight from an uploaded digital model); the material – stored in a VAT – can be UV or daylight resin.

SLA, DLP and LCD are often the most mentioned processes when talking about resin 3D printing, yet other processes are being developed and commercialized – processes such as inkjet 3D printing, Digital Light Synthesis ™ or even the recently launched Viscous Lithography Manufacturing (VLM)TM technology. Interestingly, no matter what resin 3D printing process is, the stake is still the same at the materials level: what does it take to use them in series or industrial production?

First of all, let’s recognize that extraordinary advances in “single-cure”, “dual-cure” resin technology or UV chemistries (which have expanded from various shades of the same rigid, brittle materials to a wider spectrum of properties including rigid, tough resins, and elastomers) have allowed space for innovation. The problem that hinders series or industrial production the most is likely to be the constant comparison with injection molded thermoplastics and what they enable in terms of production. The truth is SLA, DLP or any other types of resin 3D printing technology can achieve different purposes when it comes to manufacturing – not to mention that they are being improved at their own pace and across different features, but this comparison is probably the first argument that prevent industrial users to appreciate their capabilities.

That being said, despite the advancements that are currently being made at the materials level, some resin 3D printing processes themselves are not ready to reach a new stage in manufacturingyet. 3D inkjet printing for instance (a low-temperature, low-pressure process that involves the deposition of liquid materials or solid suspensions), is natively multi-material but it has often been hindered by non-end-use applications. Interestingly, the current developments in resin materials show a focus on both low and high viscosity resins.

Surprisingly, viscosity is usually mentioned as one of the most important rheological parameters that enables to determine optimal processing conditions for FDM and Pellet AM. Just like density, viscosity helps to give information about the material itself. “As a rule of thumb “the higher the viscosity of 3D resins the higher achievable mechanical properties and safety”, Nika Borges, Sales & Marketing Manager for materials producer 3Dresyns says, speaking of resin 3D printing.

In practice, two schools of thought are currently emerging when it comes to viscosity: the small group of people that see the advantages of low viscosity resins for SLA 3D printing and the other one that sees a range of opportunities in high viscosity resins. The role of resin viscosity has been largely explored for stereolithography, where a very low viscosity material is preferred. For Borges, the problem with low viscosity 3D resins, is that they “exhibit inferior mechanical properties, such as poor toughness and mechanical strength. They contain low viscosity monomers, [which can lead to] high toxicity (…).” The materials producer explains that “despite having lower viscosity”, its monomer free and monomer-based 3D resins stand out from the crowd as they“exhibit unique high performance and safety.”

High viscosity resins on the other hand, obviously deliver higher overall mechanical properties and safety.

“A higher viscosity means a thicker resin. This has an effect on the reflux of the polymer and on the movements of the platform. If you know the volume of your 3D model and the density of the material you selected, you can easily calculate the weight of your 3D printed model”, resin materials producer Liqcreate said.

While high viscosity resins contribute in “making ultra-high performance safe materials”, Borges notes that at the production level, “they can be printed in most commercial printers at 25-50ºC after installing a heater.”

Whether we talk about low or high viscosity, we’ll keep in mind that the viscosity of the resin does not depend on accuracy. High viscosity resin does not mean that it is easy to accumulate in the voids of the prints, low viscosity resin does not mean that it is not easy to accumulate either.

No matter what type of materials are used, 3Dresyns currently urges 3D printer manufacturers to develop affordable and reliable bigger printers based on MLCD and DLP technology. At the end of the day, the variability related to each 3D printer can greatly influence the result of the finished product. Taking the example of light power, Borges explains:

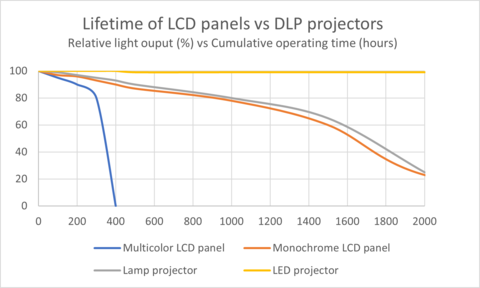

“Depending on the chosen 3D printer technology, its design, configuration, light wavelength, power, its distribution across the vat and the cumulative operating time, the real light power available across the vat for printing may vary significantly, and consequently as well the printing settings for similar printers and even from unit to unit of the same model due to small production differences among units. The following graphs show the typical light output decays vs cumulative operating time of standard multicolor RGB LCD panels, monochrome LCD panels, digital lamp projectors and LED projectors, all typically used in SLA, DLP & LCD 3D printers.

Unfortunately, light power varies and decays vs cumulative operating time. Even different units of the same model, new as supplied, often have 10-15% light power differences, which affect the overall printing results. Additionally, as shown on the graph above, light power decays versus the cumulative operating time of the printer. Light power variability upon usage and lack of light power control over time need to be addressed to promote the 3D industrial revolution. Right now, unfortunately, only few printer manufacturers have addressed these basic problems.

Lack of light power control, monitorization and prevention of its decay are some of the main reasons for frustration, printing problems, variability, or failure. Professional printing requires printers with constant specifications to promote the shift from traditional manufacturing into additive manufacturing.”

Today, the issues of costs and applications continue to enliven discussions across resin 3D printing users.

As far as applications are concerned, advanced users hope to see further developments with photo-curable composite or nanocomposite resins.

It’s currently a Holy Grail to scale adoption of photopolymer-based resins because a great number of photopolymer components’ price depend on their use in the coatings and ink jet industry where they were primarily used. While large volume part production may enable to reduce raw material costs, technologies and service providers could further educate the user on the ability of a technology to create a product whose value is worth a new price.

Composites.

Composites are fascinating materials. For those who are not familiar with composites yet, please note that a composite refers to a thermoset or thermoplastic polymer matrix material reinforced with continuous or discontinuous fibers. Interestingly, those fibers could be carbon fiber, glass fiber, or natural fibers such as jute, flax, aramid or basalt fiber.

As we said in an exclusive feature dedicated to composites 3D printing, when Additive Manufacturing came to composites fabrication, we did not expect this combination to work and lead to the development of some niche, yet interesting applications for the industry.

If these materials have won their place in various applications made possible through additive manufacturing, the best part of it is that, there is a wide range of AM techniques that can actually process them: laminated object manufacturing, powder-bed fusion, VAT photopolymerization and material extrusion (this one including 5 different sub-segments) – each of them featuring its share of pros and cons:

| Techniques | Advantages | Disadvantages | Fiber alignment |

| Laminated object manufacturing | Low cost Parts with high strength can be produced No requirement of support structrues | Higher wastage of materialIt is relatively difficult to build parts with complex cavities | Random fiber orientation Uniform direction of the fiber |

| Powder-bed fusion | Support structures can be removed easilyComposites with higher reinforcement of loading can be achievedFine resolutionPowders that remains unused can be reutilized | Rough surface finishSlow printingNot possible to fabricate composites with long fibersExpensiveHigh porosity in the final parts | Random fiber orientation |

| VAT photopolymerization | Fibers can be aligned randomly Finer resolution | Formation of bubbles takes placeLimited materials can only be used. Sedimentation of fiber in resin Increased resin viscosity with the addition of fibersThe issue with the penetration of UV rays | Random fiber orientationAlong the direction of electric-fieldAlong the direction of magnetic-fieldAlong the direction of layingIn accordance with the fiber pattern of the mat |

| Material extrusion | Easy to fabricateEconomical Multi-material capability Print-heads can be easily modified | Degradation of the nozzleObious layer-by-layer effectAt higher reinforcement loading, nozzle gets clogged. | Along the direction of printing |

Advancing composites AM mainly depends on the partnerships between manufacturers and adopters. According to Regina Pynn, expert at Hexcel, “end users drive the technical requirements, and that’s what flows up through the supply chain to inform what machine and material producers focus on. The tailoring of material properties you can achieve in composites and the differences that build orientation can drive in composite materials, make that link a real driver for innovation.”

That being said, it’s interesting to remember that composites AM opens up new possibilities for lightweighting, when experts are looking to transitioning from metal to polymer. “Lightweighting has been a driver in traditional composites adoption and that trend continues in additive”, Hexcel recalls. Indeed, while strength and stiffness are often mentioned as desired properties delivered when leveraging composites (and especially continuous fiber) with AM, they are not as powerful as the advantage of lightweighting.

“When we’re replacing metallic components with HexPEKK-100, which is an SLS fabricated CF PEKK material, the weight savings for our aerospace customers is as important as the cost savings we bring to the program. Composites also lend themselves to customization of materials properties. Conductivity, flexibility, impact resistance: all these areas affect where a material can be controlled and adjusted in a composites material system”, the expert outlines.

Despite these benefits, composite AM still presents some grey areas when it comes to the opportunities that carbon and glass fiber reinforced polymers (CFRP and GFRP) can enable. Indeed, CFRP (which stands for carbon-fiber reinforced plastic) is lightweight and has low density. It is also extremely conductive and highly expensive which is often considered as a key limitation in several applications.

The glass-fiber reinforced plastic on the other hand (GFRP), has a medium weight and medium density. It is insulative and less expensive.

To open more room for opportunities, Hexcel prefers to focus on new properties composites enable when combined with AM – that one cannot achieve with conventional manufacturing processes. “At this phase of adoption most customers are trading AM versus traditional manufacturing methods. Composite AM has a great advantage when it comes to this competition. Against traditionally metallic components composites can bring properties like EM signal shielding, which we have in our HexPEKK-EM offering, that previously were a show stopped for non-metallic replacement.”

Furthermore, another grey area is the current process around material allowable generation along with machine and part qualification. This process is not specific to composites as it is also what slows down the adoption of AM in general. The truth is, for a great number of AM users – especially those coming from a demanding industry, it’s a real bottleneck to predict all materials allowables for a specific part. Due to the lack of accurate data, engineers and material experts should redesign the ideal material each time or take over the development of AM process simulation to predict as-built material characteristic.

“For many of our aerospace composite customers it’s the current process around material allowable generation along with machine and part qualification, so for Hexcel that has led to us focusing on fleet homogeneity and material allowable work to give the technical community the information they need to design the material without starting at the beginning for each new part. Long term that means leaning more on in-process or post-process verification, like NDI or quality sampling, and less on locking down every specific build detail for every specific piece. You can move a lot faster with adoption if everyone agrees on what good hardware looks like at the end and you’re giving the manufacturing team the ability to change and optimize the process to get there. That feeds greater efficiency, which gives the adopters a broader business case for where this technology makes sense”, Hexcel notes.

Filaments.

3D printing starts with filaments, advances thanks to filaments (and other materials obviously) and is currently in the middle of a revolution thanks to opportunities for more sustainable and local production created by filaments. However, a number of questions continue to raise debate across industries, questions regarding sustainability of materials, certification and metal 3D printing. As far as sustainability is concerned, let’s remember that 3D printing has always claimed to be sustainable due to its reduced wastage in manufacturing compared to other forms of manufacturing like machining. However, the most popular materials have always been carbon-based polymers, which are inherently not sustainable since they are derived from non-renewable resources. When it comes to filaments precisely, some material producers have started highlighting the “green benefits” of their materials.

In reality, they are quite “unclear about how sustainable [their materials] are, e.g. percentage of recycled material, the provenience of the recycled portion, etc. To increase the adoption of sustainable materials in production, customers have to trust that the material is sustainable with good engineering properties and, above all that, it will be reproducible”, Thiago Medeiros Araujo, LUVOCOM 3F Global Product Manager shares.

Characteristics like recyclability and reusability were a trend that came into full force in 2021 as a different approach to sustainability in 3D Printing but mentioning them alone is no longer enough today.

Certification.

The question regarding certification has often been asked by domestic users who needed to ensure that their materials meet an indoor air quality safety standard. In an industrial setting, this characteristic tends to reassure engineers on the quality of the material used for their projects. While certification provides the material a certain legitimacy, Medeiros Araujo draws attention on the fact that it does not necessarily mean that this material delivers “industrial capabilities”:

“Certifying a material per se in 3D printing is not something that adds value, as in most cases, its properties are directly related to the way the material was printed. However, having an independently certified build process has an enormous impact on the adoption of the material as it gives the customer enough confidence and trust to use the material straight away. So, it saves the user not only costs for having the material assessed but it also reduces the time for adoption”.

Metal 3D printing.

Metal-polymer filament extrusion is currently gaining momentum as professionals are continuously looking for affordable metal 3D printing solution.

From a commercial standpoint, this business segment increasingly grows, giving the opportunity to industrial FDM 3D printer manufacturers such as 3DGence to develop machines capable of processing metal 3D printing filaments or to material producers like Nanovia or BASF to develop metallic filaments.

“However, we have to bear in mind that it is not only about producing the metallic filament but providing the customer with the whole structure for further processing of the parts, e.g. de-binding and sintering”, Lehvoss’ expert alerts.

Indeed, at the manufacturing level, metal 3D printing filaments and other materials that contain additives often need to be sintered to increase part density, helping users achieve the full set of high-performance mechanical properties.

Moving forward, one of the main challenges of the industry remains to achieve a “first time right” solution, no matter what material is used. And to do this, it’s important to recall that it’s a stage that can be reached through collaborations between various stakeholders. As Medeiros Araujo said, “each partnership demands a lot of commitment and effort from both sides to make it a flawless experience on the additive manufacturing journey of the customers.”

Notes to the readers

The feature has first been published in the March/April edition of 3D ADEPT Mag. above has highlighted various insights from material producers on topics that currently raise debate across industries. The main opinions shared on this topic are coming from 3Dresyns, Hexcel, and Lehvoss Group. Their representative shares insights into resins, composites and filaments.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com.