Founded by Janne Pihlajamäki seven years ago, miniFactory manufactures 3D printers. The company is based in a small country which has a population of roughly 6 million; an area where, according to our resource person, additive manufacturing does not move at fast pace as in bigger European countries.

Nevertheless, as every company in this industry (at least those who survived the first years during which additive manufacturing was not yet considered as a disruptive technology for various industries), miniFactory experienced several stages of development.

Over time, the company’s business model has taken shape and has evolved with market realities and today’s some of these market realities concern polymers. What is intriguing with these materials is the fact that, having the right polymer for a specific application is not enough, the key to successful manufacturing using polymers relies on the perfect match between a specific polymer and a specific industrial 3D printer. That was the challenge of miniFactory.

In this #OpinionoftheWeek, Olli Pihlajamäki tells us more about how they overcome this challenge.

A few words on Olli Pihlajamäki

Olli Pihlajamäki is one of those employees who bears the company’s values in his DNA. It was a kind of duty for him to give a helping hand here and there as the brother of the founder. He had to learn from scratch before his official appointment to the position of Sales and Marketing Director.

His point of view today is therefore the one of someone who perfectly knows the company and what it is capable to achieve for the market.

Tell us more about the company and what raised your interest in polymer materials

With 3D printers available in 400 schools and in over 500 companies in Finland, every 3D printer we have designed so far has been made based on customers feedback.

miniFactory has designed 5 3D printer models in total. An analysis of the consumption habits on the market raised our interest in ultra-polymers. And that’s how we started to develop an industrial machine that might be perfectly compatible with these materials.

There are so many families of polymers but miniFactory focuses on three main types of materials: ULTEM, PEKK, PPSU and PEEK. Why this emphasis on these materials?

This focus is due to the mechanical properties we want the printed part to have. Simply put, these polymers integrate high-performance properties, which means higher heat deflection, mechanical strength and chemical resistance properties compared to engineering polymers.

Furthermore, these properties enable to meet requirements of various and demanding industries.

At the technical level, it should be noted that every polymer has a glass transition temperature (Tg), during which it stays in structural relaxation and polymer chains are oriented randomly. High performance polymers are processed within the temperature range 145°C – 220°C (Tg) in the heated chamber.

A miniFactory 3D printer on the other hand has a heated chamber that might reach up to 250°C, which allows the production of dimensional accurate parts using these polymers.

When asked if there is a simple way to differentiate those materials, Olli Pihlajamäki explained us that polymer materials share some similarities such as their inherent flame resistance, their mechanical strength or even their chemical resistance. However, every polymer integrates specific properties that make it the ideal option for certain applications and communication comes into play to draw these differences. As a matter of fact, two polymers can provide mechanical strength properties to parts but they will not provide them at the same degree.

What advantages do they provide in an AM process compared to other types of materials?

First, these high-performance polymers are compatible with FFF technology. Parts manufacturing could be complex, especially when dealing with integrated features in the process that aim to make 3D printing a reasonable choice.

Furthermore, the truth is that a specific part that has been designed and produced using traditional manufacturing is not necessarily cost-effective when using additive manufacturing. However, the main reason that explains the choice for polymer 3D printing is the fact that raw material prices for these polymers can be 10-30 times more expensive than basic engineering polymers. This is due to high melting points and glass transition temperatures of polymers which are not easy to process in traditional manufacturing processes.

In injection moulding for instance, the mould needs to be heated, and this requires time and money. CNC machining on its side remains an expensive option given the higher price of raw material.

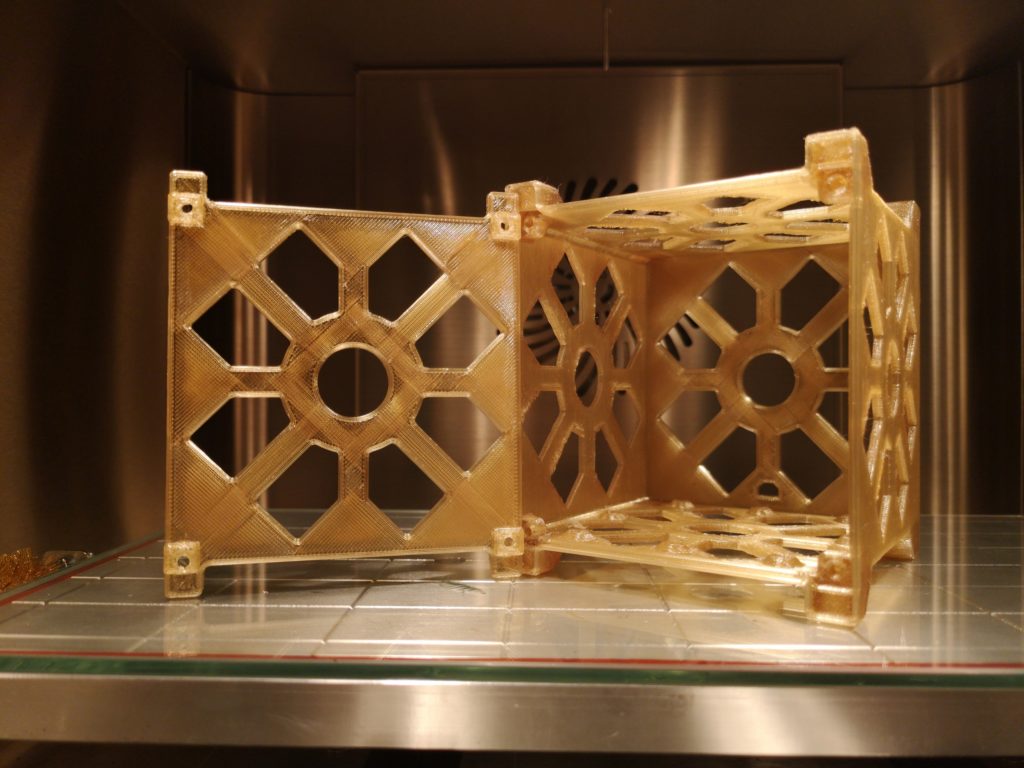

The cubesat is printed with PEKK-A, a material produced by ARMOR Group

For all of these reasons, professionals opt for 3D printing to produce end-use parts and in most cases, the latter are basic brackets, frames, seals, ducts etc. The cost of raw material and the cost of traditional manufacturing methods make 3D printing, a cost-effective choice for companies. Therefore, with more complex or bigger parts, much more money can be saved.

R&D divisions of companies increasingly focus on polymers and yet metallic powders seem to represent a bigger market share in the AM industry. How do you explain that?

I truly believe that there is a place for every material and every technology on the market. There is a wide range of applications where metal AM is not able to replace polymers and the reverse is true.

In many structures and machines, weight is the biggest challenge and companies are trying to overcome that. In these specific cases, polymers play a key role to improve manufacturing.

Some polymers can also reduce maintenance leading to more uptime and lower costs. Moreover, since they withstand high temperatures and harsh chemicals, they are able to match thermal expansions of metal.

What are the different geographical and sectorial markets that MiniFactory targets? What will be miniFactory’s strategy to further penetrate the market?

Throughout the year, our main target will be to build up our distribution network in Europe and Asia. This year will definitely be a great one for us: in addition to ongoing discussions to make our products available in other European countries and in Asia, the first batch of our next machines has been sold out before the production actually started.

During the next few weeks, we will unveil our authorized partners in Europe (the first one being MakerPoint in the Netherlands) and we will further a close cooperation with material producers such as SABIC, KIMYA, ARKEMA, VICTREX and SOLVAY.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});