With the goal of exploring the Solar System, China has successful sent the Long March-5 carrier rocket to the planned orbit. The rocket was designed to bear 25 tons of payload in low earth orbit and 14 tons in geo-synchronous transfer orbit.

With a 5 meters-diameter and four 3.35-meter boosters, the rocket required various manufacturing stages and the utilization of intelligent technologies for its manufacturing.

One of these technologies includes Farsoon’s additive manufacturing for plastic parts. The HT1001P of the 3D printer manufacturer was specifically leveraged to produce a static firing skirt.

Fabricated in 50 separated pieces of 370 x 100 x 125mm before being assembled into a 5000mm-diameter cylinder structure, the static firing skirt delivers a temporary structural medium between the stage and the aft support ring to protect the unlocking device. “It is cylindrically shaped and is fitted with internal and external lift points, facilitating stage handling”, the scientists describe.

Such component is usually leveraged in rocketry circles as part of a “staging process” which requires well-designed inter-stage structure system with functional & durable parts. That’s why, for the manufacturing process, the scientists team opted for the Farsoon HT1001P laser sintering technology and the high performance material FS3300PA.

With a build envelope of 1000 x 500 x 450mm, the machine delivers strength and toughness, and does not require a lot of post-processing for water-proofing when it processes the FS3300PA material.

If Farsoon’s technology is currently being leveraged by an aerospace specialist, it is the first time that we discover its technology capabilities in the Space field, a use case that also reflects AM advancements in China.

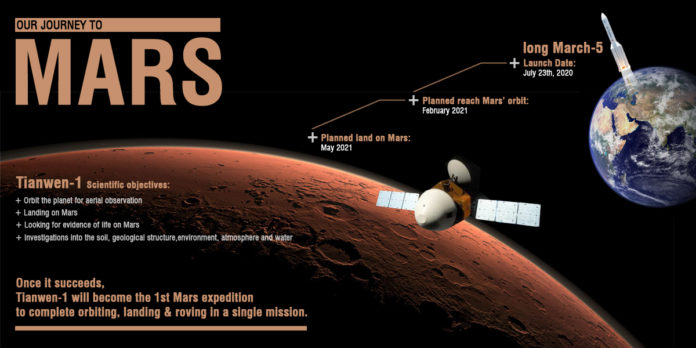

“Tianwen-1 has now successfully carried out its first orbital correction on August 2nd, after travelling more than 230 hours in space and 3 million kilometers away from the earth, according to the China National Space Administration (CNSA)” the company confirmed.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com