Home =

Thermwood - search results

If you're not happy with the results, please do another search

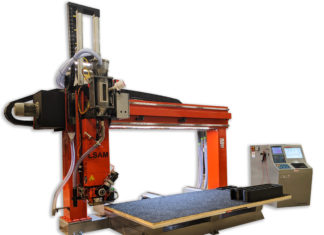

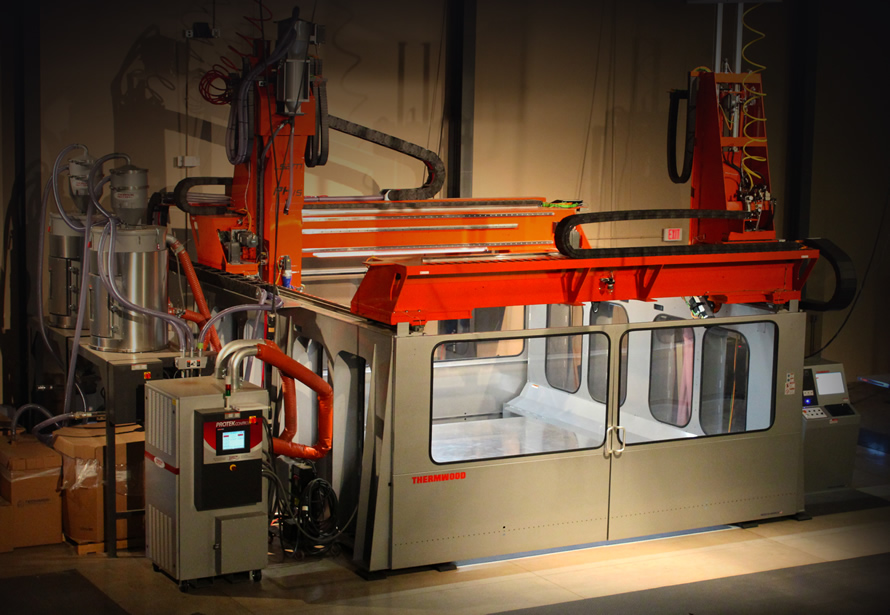

Thermwood completes first LSAM 1010 3D Printer with Fixed Table

From moving table to fixed table

Thermwood unveils the first of a new type of additive print and trim system, the LSAM 1010.

The announcement follows...

Back to basics: “print only”, the ultimate goal of Thermwood’s new LSAM system

A wide range of entry-level 3D printers exists for desktop 3D printers, but the market is not that much fulfilled for those who would...

LSAM: Thermwood ensures automated print temperature control and enhances fusion between layers

In the January-February issue of 3D ADEPT Mag (Focus on YOU Series – pp 18-21), Thermwood told 3D ADEPT Media that one of the...

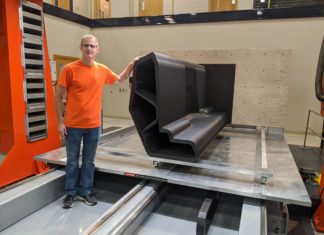

Thermwood reveals a New Approach to 3D Printing a Yacht Hull Mold

Thermwood recently 3D printed several sections from a 51-foot long yacht hull mold to demonstrate how only a single mold may be needed for...

New approach validates Thermwood’s Large Scale Additive Manufacturing capabilities

Among the companies that can pride themselves on developing a true Large Scale Additive Manufacturing (LSAM) is Thermwood. The secret behind the company’s methodology...

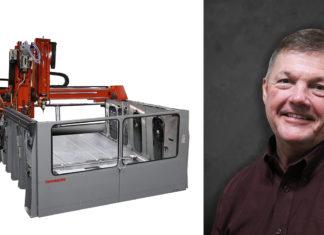

Dennis Palmer on the possibilities of Thermwood’s Large Scale Additive Manufacturing

Another company that positions itself in the large format 3D printing segment is Thermwood. With over 50 years of experience in conventional manufacturing processes...

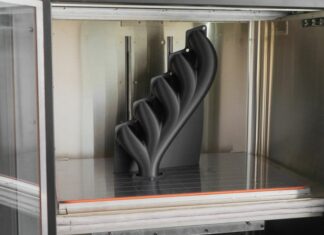

Thermwood’s large-scale additive manufacturing machine improved

It's a one-ton machine and a half-toolhead that Thermwood updated. In addition, thanks to a CNC milling toolhead, one can perceive a hybrid approach...

How does LSAM advance tidal energy manufacturing? New project shows how.

Tidal energy manufacturing involves creating components for various energy extraction technologies, such as tidal barrages, which are like dams, and tidal stream generators, which are like underwater...

AON3D claims to cut print times up to 54% with physics-based slicing

Remember when we told you that two critical factors drive efficiency in manufacturing: production throughput and workflow integration? Well this is not only the case for large-scale...

Vittori, Totum 3D, and ShapeUp Studios plan to use AM for hypercars, eVTOL, and electric jet programs.

Vittori’s roadmap is packed with projects that involve the use of additive manufacturing for hypercars, eVTOL, and electric jet programs. The company that engineers...