Home =

M1 Basic - search results

If you're not happy with the results, please do another search

heliguyTM optimizes its 3D printed drone parts using AM Solutions’ M1 Basic

heliguyTM is a commercial drone innovator who has integrated Additive Manufacturing and its associated ecosystem of technologies to facilitate agile in-house manufacturing.

With the goal of...

Oerlikon Balzers adds two systems from AM Solutions to enhance surface finishing of 3D printed components

Oerlikon Balzers, a technology brand of the Oerlikon Group, is the latest company that decided to invest in the M1 Basic systems from AM...

Klaus Stöcker Metallbearbeitung leverages mass finishing as an alternative to chemical smoothing for its 3D printed parts

Six years after integrating AM as part of its production portfolio, Klaus Stöcker Metallbearbeitung, a company that initially only provided machining services such as...

The National Manufacturing Institute Scotland leverages AM Solutions’ 3D Printing Post-Processing Solution as part of a research project

Another M1 Basic solution has found a new home in the facilities of the National Manufacturing Institute Scotland (NMIS). The post-processing solution developed and...

3D printing News Round-Up: Sauber Technologies, AM Solutions, Anisoprint, Wematter and Nexa3D

Who has started shipment of its products? Who is working on the development of a new material? And who will distribute what? This edition...

From product design to the “final surface finish”: Rösler delivers automated solutions for all stages of post-processing in AM

Rösler seized the opportunity at Formnext 2019, to officially introduce its new brand AM Solutions, the latest technologies and its new partnership with HP.Indeed,...

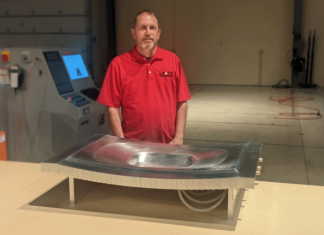

Thermwood continues to demonstrate the viability of its Cut Layer Additive solution – this time with a large aluminum mold

Machine manufacturer Thermwood continues to give users the ability to produce parts with the benefits of the additive process using materials one cannot print...

Software Automation In Additive Manufacturing: Where Are You In Your Journey?

When early users of Additive Manufacturing technologies started leveraging these technologies, the most important aspect, if not the only one, was to determine if...

Unveiling the disguised complexities of Wire-Arc Additive Manufacturing

With a first patent granted in the 1920s, Wire-Arc Additive Manufacturing, short for WAAM, is certainly one of the oldest AM processes that exist,...

Thermwood completes first LSAM 1010 3D Printer with Fixed Table

From moving table to fixed table

Thermwood unveils the first of a new type of additive print and trim system, the LSAM 1010.

The announcement follows...