Home =

Spee3D - search results

If you're not happy with the results, please do another search

RusselSmith firmly positions itself as an AM reseller in West Africa, partners with SPEE3D

RusselSmith, an organization qualified by the Nigerian Upstream Petroleum Regulatory Commission (NUPRC) to deploy industrial non-metallic additive manufacturing solutions in the oil and gas industry, and the current unique African company member of AMGTA,...

First look at SPEE3D’s latest metal 3D printer: “TITANSPEE3D”

On the heels of the launch of its on-site metal AM solution, SPEE3D announces the launch of a large-format metal 3D printer. Named TitanSPEE3D, the new 3D printer would provide high design freedom and...

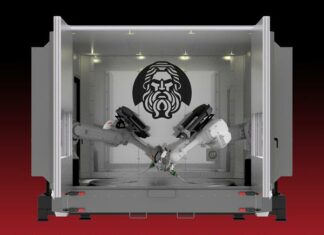

SPEE3D unveils on-site metal AM solution for the defense industry

SPEE3D, Australian metal additive manufacturing company, has unveiled its Expeditionary Manufacturing Unit (EMU), a complete on-site mobile additive manufacturing solution. EMU combines SPEE3D’s expeditionary metal 3D printer, XSPEE3D, with its SPEE3Dcell post-processing and testing...

SPEE3D to develop SUBSAFE manufacturing materials with Cold Spray Additive Manufacturing

The US Navy has chosen metal AM company SPEE3D to develop materials as a part of a Naval Sea Systems Command (NAVSEA) project related to Expeditionary Maintenance and Sustainment that achieve Submarine Safety Program...

Metal 3D Printing: SPEE3D unveils New High Velocity Phaser Nozzle for a wider range of hard phase materials

SPEE3D has developed a new ultra high energy nozzle designed to work with a wider range of hard phase materials. Named SPEE3D Phaser nozzle, it delivers a significant increase in deposition velocity.

As a reminder,...

SPEE3D has developed a new way to 3D print rocket engines

Manufacturing space components is a billion-dollar industry set to experience strong growth in demand over the next five years. However, organisations across the world currently face one common challenge: long lead times for production-ready...

SPEE3D launches a Free-To-Play Metal 3D Printing Game

If you are looking for an entertaining and edifying activity for this week-end, you might want to consider SPEE3DCraft, a free-to-download metal 3D printing simulator game. Developed by Cold spray 3D printer manufacturer SPEE3D, the...

Australian army to leverage SPEE3D metal additive manufacturing for their operations

The Australian army invests $1.5 million investment into a 12-month pilot program of SPEE3D metal additive manufacturing technology.

The Australian manufacturer partnered with the Advanced Manufacturing Alliance (AMA) and Charles Darwin University (CDU) to deliver...

SPEE3D’s technology is now part of FIT Additive Manufacturing Group’s technologies

The original supersonic 3D deposition technology is now part of FIT Additive Manufacturing Group’s technologies. As a reminder, the technology of SPEE3D was originally intended for military and repair applications. In this process, the...

Australian Army 3D Prints and Certifies armored vehicle parts in the field

Remember when we explained that AM can be a good production candidate for expeditionary manufacturing? Well, here is a great example of how expeditionary Metal 3D Printing can improve Defence readiness.

The Australian Army have...