Home =

Sandvik - search results

If you're not happy with the results, please do another search

Sandvik to exit stake in BEAMIT as part of strategic shift

As part of its latest move to refocus business strategies, Swedish-based Sandvik announced plans to sell off its minority stake in Italian Additive Manufacturing (AM) service provider BEAMIT. In doing so, Sandvik aligns with...

Sandvik unveils a hot-work tool steel for both AM and conventional manufacturing processes

Known for its metal powders & Additive Manufacturing solutions, Sandvik has launched Osprey® HWTS 50, a hot-work tool steel powder with improved printability. Designed for laser-based Additive Manufacturing, it can also be used with...

Sandvik unveils new copper-based alloy designed for AM & MIM

Material producer Sandvik has developed a copper-based metal powder tailored for applications requiring excellent mechanical strength at high temperatures while maintaining high electrical and thermal conductivity. Named Osprey® C18150, this powder is ideal for...

Sandvik unveils 3D printed components in cemented carbide

Materials producer Sandvik continues to expand its portfolio of materials and applications in additive manufacturing. The expert in hard materials has introduced 3D printed cemented carbide developed with a patented process.

Due to their composite structure...

Sandvik and BEAMIT unveil new capabilities for 3D printed components in super-duplex stainless steel

Osprey® 2507 components outperforming several traditional counterparts

With industries such asoffshore- and marine that increasingly require on-demand production of spare parts, a better management of supply chain and a decrease in material waste, material producers...

Immensa Additive Manufacturing Group Partners With Sandvik – Advancing Additive Manufacturing Across The Middle East

Sandvik Additive Manufacturing and part subsidiary BEAMIT establish a strategic partnership with Immensa Additive Manufacturing Group – the leading AM solution provider in the MENA region.Immensa Technology Labs is part of the high-technology Immensa Additive...

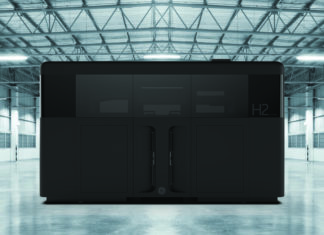

Sandvik becomes a strategic partner in GE Additive’s Binder Jet Program

Sandvik has just joined GE Additive’s Binder Jet Partner Program. Since Sandvik is a materials producer, the announcement might surprise one or two as GE Additive already has a materials company in its additive...

SANDVIK achieves medical certification to safely produce 3D Printed implants

Sandvik’s new powder plant has just received the ‘ISO 13485:2016’ medical certification for Osprey® titanium powders. The Sweden-based metal powder producer will now safely leverage these powders for additive manufacturing applications in the medical...

Sandvik Additive Manufacturing achieves aerospace certification for its new powder plant

The aerospace industry can now leverage Sandvik’s powder plant for titanium and nickel-based superalloys with serenity as it has received the ‘AS9100 Revision D’ certification.

The new plant for gas-atomized powders is based in Sandviken,...

Sandvik and Renishaw to work on the qualification of new additive manufacturing materials

“With our 157-year materials knowledge, our comprehensive range of in-house Osprey® steels, duplex and super-duplex stainless steels, as well as nickel-based alloys and our new titanium powders, Sandvik now offers the widest range of AM...