Not many companies can pride themselves of having a fantastic 2020. DyeMansion is one of them. Thousands of reasons can explain this but there is a very great chance that if they’d had a terrible year, the contagious energy radiating from this team would have turned it into something positive.

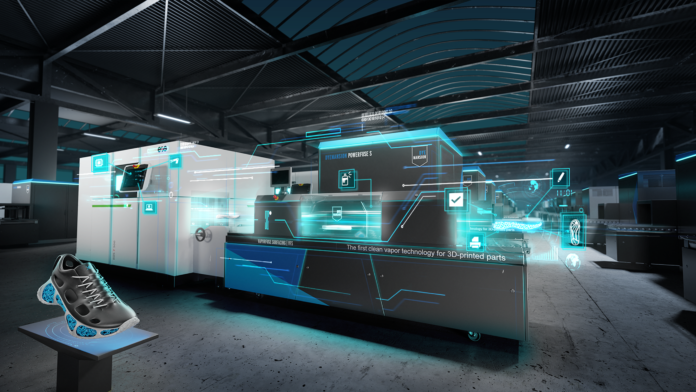

The opening of the US branch in Texas, a fundraising of $14M USD, the launch of beta program for the Vaporfuse as part of the Green Deal call, the “POLYLINE project”, and the “factory of the future” project are some of the things that have made DyeMansion’s year busy – and will continue to keep the team busy throughout the upcoming year.

DyeMansion’s core business is to turn 3D-printed raw parts into high-value products using its Additive Manufacturing finishing systems. To achieve this mission, the company continuously adapts its strategy to current challenges raised by the industry. Needless to say that this year, flexible on-demand production has completed a list of challenges raised by industrialization within industries, hence this focal point in most AM companies’ growth strategy.

In between industrialization and flexible on-demand production

For DyeMansion, these major tasks can’t be accomplished alone hence the new partnership signed with Siemens. With a wide range of trademarks, Siemens is at the heart of several technology developments initiated by both technology providers and users of Additive Manufacturing.

The company’s automation technology is integrated into DyeMansion’s Powerfuse S, and allows for the use of various digital services.

“The automated chain of coordinated production steps from all suppliers, from design and printing to post-processing, as well as end-to-end IT integration, is crucial for high productivity and maximum flexibility. This applies to series parts as well as to a highly flexible lot-size-1 production for individualized products or spare parts,” explains Dr. Karsten Heuser, Vice President Additive Manufacturing at Siemens Digital Industries, and continues: “With the end-to-end digitization and automation solutions from Siemens, we have succeeded, together with our partners EOS and DyeMansion, in creating a seamlessly integrated end-to-end value chain for industrial additive manufacturing with selective laser sintering and industrial post-processing solutions using polymers.”

In practice, what does it mean?

During their press conference, Felix Ewald CEO & Co-founder of the company, lay emphasis on the fact that “industry 4.0” is not a buzzword. Ewald explains that the wordsindustrialization & industry 4.0 have been used for a few years now. A lot has been said about that with very few actions. Industry 4.0 is at the intersection of several fields – as shown in the image below – and it’s important to find a good balance between all of them. “This is not about marketing – Ewald said -, it’s about finding the good balance between automation and industrialization”.

As digitalisation is a key highlight of this partnership between both companies, Philipp Kramer, CTO of DyeMansion outlines the three pillars where they will focus: remote access to the manufacturing platform, digital shopfloor integration thanks to partners like SAP, Link3D, 3YOURMIND, Authentise & Microsoft Dynamics 365, as well as monitoring & data analysis.

“Remote Access ensures fast root cause analysis and problem solving via secured VPN connections. Integrating the physical system to the digital shopfloor enables the communication to MES and ERP systems using the OPC-UA protocol. Completing those pillars, DyeMansion has also developed a real-time monitoring dashboard for the Powerfuse S to observe the system status and sensor data. This sets the basis to use applications in industrial IoT clouds like the Siemens MindShpere in the future” Kramer said.

“Localized industrial post-processing for 3D printed parts”

In few weeks, AM users across the world could request the industrial post-processing of their 3D printed parts via a partner of the German company.

Indeed, the company’s recently launched industrial post-processing platform brings together production and sales partners that will ensure this service in their local region.

Last but not least, sales partners provide complete AM process chains and consulting to their customers for inhouse manufacturing.

“New partners on the sales side are, 3Dees from the Czech Republic and Imagenet based in the Unites States who joined the platform as certified DyeMansion resellers serving local customers in their region. As a complement, DyeMansion’s productions partners serve customers on all continents in a competitive manner every day in the most efficient way. On the production side, new partners are Paragon, Incremental Engineering, Printing Portal and the Digital Manufacturing Centre from the UK as well as Custom Implants and Mausa based in Spain”, the company announced in a press communication.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com