TU/e has been one of the first players that decided to explore construction 3D printing in the Netherlands. What was the focus of the research at that time?

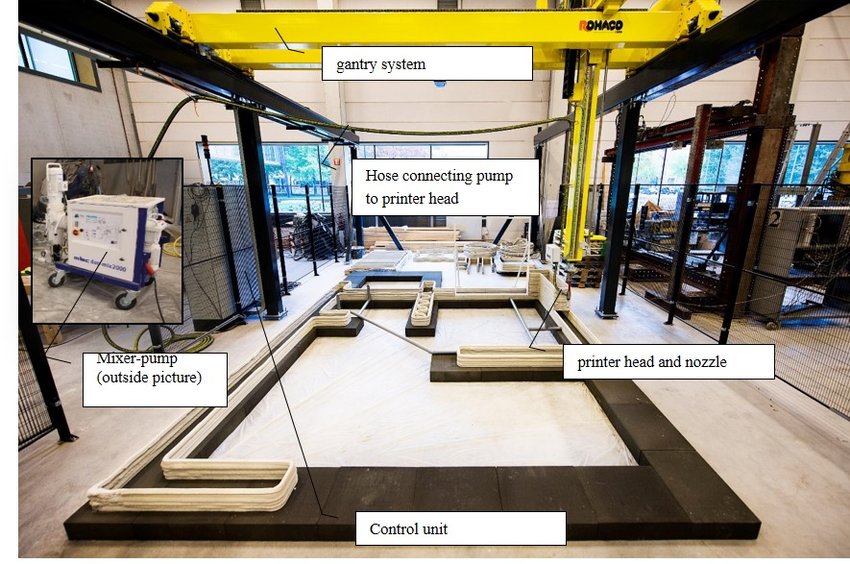

In the very beginning, the focus was on the printing system – the concept of a machine that could print big parts for bridges, houses. The biggest priority then was to guarantee buildability, preventing collapse, for the height required for these elements.

And how far have they evolved today?

The research went a long way since then, with the study of the reinforcement, real-time control of the printing system and the development of new mixes. The materials used in our 3D printer have evolved from a commercially available cement mortar to new materials (sustainable and functional). We are now developing new compositions that contain added functionalities – self-sensing, self-healing, as an example. A top priority now is to reduce the cement content and move to sustainable binders. Another priority is to increase the aggregate size, shifting from a mortar to concrete.

There are a variety of 3D printing methods used in construction today, with the main ones being extrusion (concrete/cement, wax, foam, polymers), powder bonding (polymer bond, reactive bond, sintering), and additive welding. What are, according to you, the ones that have proved their worth?

For now, we use mainly the extrusion process and I think that for mortars this is the most reliable and the one that shows good potential for scaling up. Powder bonding also proved its worth but I am more sceptical about the potential for applications at the industrial scale, on-site, for example.

As part of TU/e’s research projects and even in your studies, there has always been a key focus on concrete. Why this material? What advantages does it bring that others do not have?

In the past, the focus was on concrete, more due to practical issues, however, concrete is not the focus of my research. I am the PI (leader) of two projects funded by NWO, the Dutch research council, which aim precisely at creating compositions that are sustainable and circular. My research focuses on finding alternative binders and developing smart materials for 3D printing.

What are the challenges that may arouse in developing fully customisable 3D printable materials for construction?

[These are challenges that will be further developed in the upcoming panel dedicated to the hidden complexities of construction 3D printing.]

- The adequate control of the fresh properties, pumpability, extrudability and buildability

- Finding alternatives to cement that are equally low-cost and abundant

- When working with alkali-activated materials, joining the activation step with the printing process is a complex task

You will share your expertise in the upcoming days in the next additive talks session dedicated to the hidden complexities in construction 3D printing, alongside PERI’s Head of 3D Construction Printing Dr. Fabian Meyer-Broetz and COBOD’s cofounder & Head of Americas Philip Lund-Nielsen. Are there any current projects you are working on, that you would like to share upfront?

I am currently leading two consortium projects [that I may further develop during the panel]

- Additive manufacturing of functional construction materials on-demand – Funded by NWO under the programme Materials NL: Challenges (project number: 17895).

- Additive manufacturing of sustainable concrete for zero-energy buildings – Funded by NWO under the programme High Tech Systems and Materials (project number 17967)

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com