One to watch: Vision Miner’s 22 IDEX V4 3D printer delivers high-temperature performance and production-grade reliability. Here is how.

One of the biggest limitations of desktop FDM 3D printing is that parts often lack the mechanical, thermal, and chemical properties required for demanding...

Focus | From print to pour: Choosing between wax and resin for jewelry casting patterns

For those new to or working outside of this creative sector, note that in jewelry casting, a pattern refers to a model, typically made of...

Customization at scale: Meeting consumer demands through additive manufacturing

With nearly 37 million consumer product parts 3D printed in 2023—a 7 million increase (+23%) compared to 2022—the question of whether the consumer goods...

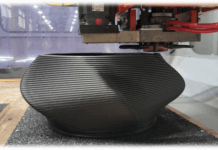

FOCUS | Evaluating production throughput and workflow integration with Thermwood’s LFAM

Two critical factors drive efficiency in manufacturing: production throughput and workflow integration. Yet, these elements are often evaluated in isolation. While that approach may...

FOCUS | Designing for depowdering: Optimizing 3D printed parts from the start

We’ve often preached the benefits of DfAM (Design for Additive Manufacturing) in terms of lightweighting, topology optimization, and part consolidation —but one critical aspect...

3DCeram Sinto on why specific technical ceramics are best suited for large, 3D printed space parts

— And how CERIA helps achieve the minimum number of iterations during manufacturing. 3DCeram will be exhibiting at Formnext, in Hall 11, C68.

Five years...

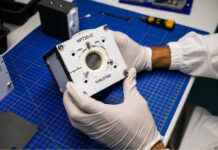

Empowering medical device manufacturers with competitive advantages to deliver the new generation of PEEK spinal implants

Additive Manufacturing unlocks PEEK’s full potential for spinal cages, but overcoming the limitations of traditionally machined implants is key. This article explores how 3D...

Why ceramic 3D printing excels for fabricating earmoulds, and where does the opportunity lie?

If you’ve ever struggled to pick out a friend’s voice in a crowded room, imagine how much harder it is for someone with hearing...

Reducing delivery times by up to 75% with a decentralized, IP-secure remote spare parts printing solution

It’s no secret that Additive Manufacturing (AM) has long been hailed as the holy grail of spare parts management across several vertical industries. In...

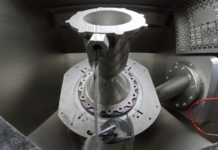

How can a 0.01% design improvement in 3D printed parts help save up to $240K/day in the semiconductor field? Lithoz discusses.

“ALD rings are not necessarily the leading application of Additive Manufacturing (AM) in the semiconductor industry, but they are the most innovative,” Johannes Homa,...