Solukon adds new feature to its entry-level automated depowdering system for medical 3D printed parts

One of the most widely known automated depowdering systems developed by Solukon is the SFM-AT800S solution but let us not forget that the company...

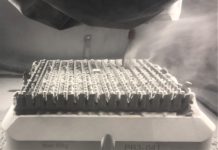

Digital Metal® launches Automated depowdering for metal binder jetting

Digital Metal® has recently unveiled an automated depowdering machine of metal binder jetted components. The announcement follows the release of pure copper in the...

Here is AM Solutions’ new media type for post processing of 3D printed thermoplastic parts and it is all about better surface finish.

AM Solutions, the AM brand of Rösler, has developed a new media type for post processing of 3D printed thermoplastic parts produced with the...

Nexa3D releases xWASH, a post-processing machine for 3D printed parts

Nexa3D has just released a new automated washer that works exclusively with its sustainable xCLEAN washing detergent. The announcement follows the recent financing round...

Solukon and Festo to explore how far they can push the level of automation for depowdering of 3D printed parts forward

Solukon and Festo joined forces in a development project to enhance efficiency when it comes to the depowdering of laser-melted metal parts. An intriguing...

Alfa Romeo Racing ORLEN to enhance post-processing tasks in AM with three S1 systems from AM Solutions

AM Solutions, the additive manufacturing brand of Rösler, has just announced a new collaboration with Alfa Romeo Racing ORLEN.

The motorsport company aims to boost...

Solukon expands distribution network in the UK, Ireland, and Canadian AM Markets

Machine Manufacturer Solukon has expanded its business activities in the UK, Ireland and Canadian Additive Manufacturing (AM) markets.

Since the beginning of the year, the...

CIPRES GmbH on the complexities of colouring for 3D printed parts and the opportunity to work with other AM solutions’ providers

Over time, I came to realize one thing about those who are passionate about Additive Manufacturing. When they are working for a leading company...

Wematter unveils new water-jet cabinet that post-processes 3D printed parts with water and compressed air

Since it emerged from its stealth mode with the release of its Gravity SLS 3D printer, Wematter has not been resting on its laurels....

Oceanz and AM-Flow deepen their collaboration for Sorting and Picking 3D Printed Parts automatically

Last year, when the pandemic was at its peak, some companies had to slow down their activities and refocus on some internal projects while...