It is as if it was yesterday that Kevin Han, CEO and founder of AON3D, told 3D ADEPT Media that improving the mechanical properties of a part is both the biggest opportunity and challenge the industry faces today; a challenge that the Canada-based 3D printer manufacturer has been working on as it releases today a new industrial 3D printer.

Named AON M2+, the high temperature 3D printer comes to provide new manufacturing opportunities through increased materials accessibility. “End-use part properties define how businesses can benefit from 3D printing,” said AON3D CEO Kevin Han. “The AON M2+ was designed by our team of material scientists to take full advantage of current and future economical thermoplastics, carbon fiber composites, and high-performance polymers like PEEK, PEKK, and ULTEM™.”

What I like about AON3D’s journey is that the company started as a 3D printing service provider. Therefore, the team is developing new products based on their experience as users of the technology. Their focus on improving industrial FFF 3D printing aims to address the limitations in terms of build volume, costs and materials that several users often meet with other 3D printer configurations.

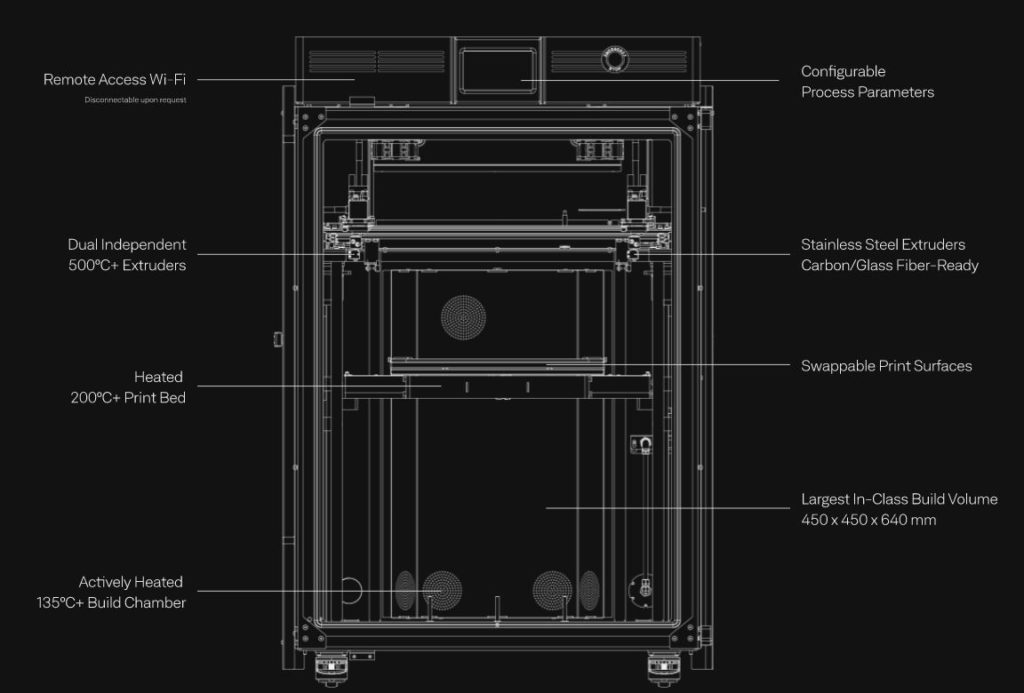

They explained in a press communication that the AON M2+ delivers high-end features and advanced material capabilities to the mid-market customer without sacrificing hardware quality. Dual independent extruders (500°C), a massive actively heated build chamber (450 x 450 x 640 mm), configurable process parameters, and ungated access to thousands of material options provide unlimited end-use printing opportunities. The AON M2+ can print materials that possess: higher strength to weight ratio than aluminum, chemical/hydrocarbon resistance, biocompatible/sterilizable properties, thermal resistance above 250°C, and more.

“Our goal is to unlock AM applications across value chains and beyond just prototyping,” said AON3D Chief Product Officer Randeep Singh. “Materials and final part properties are leading those initiatives.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com