Experts from Promation, ModuleWorks, and Multi-Scale Additive Manufacturing (MSAM) Laboratory of the University of Waterloo have explored a new method for manufacturing overhang geometries without the need of support structures.

Promation brings here its expertise in high-quality tooling, automation, and robotic systems. ModuleWorks is a software component provider for the digital manufacturing industry while by focusing on next generation additive manufacturing processes, the MSAM Lab, located at the Department of Mechanical and Mechatronics Engineering of the University of Waterloo in Canada keeps exploring novel techniques to develop advanced materials, innovative products, modeling and simulation tools, monitoring devices, closed-loop control systems, quality assurance algorithms and holistic in-situ and ex-situ characterization techniques.

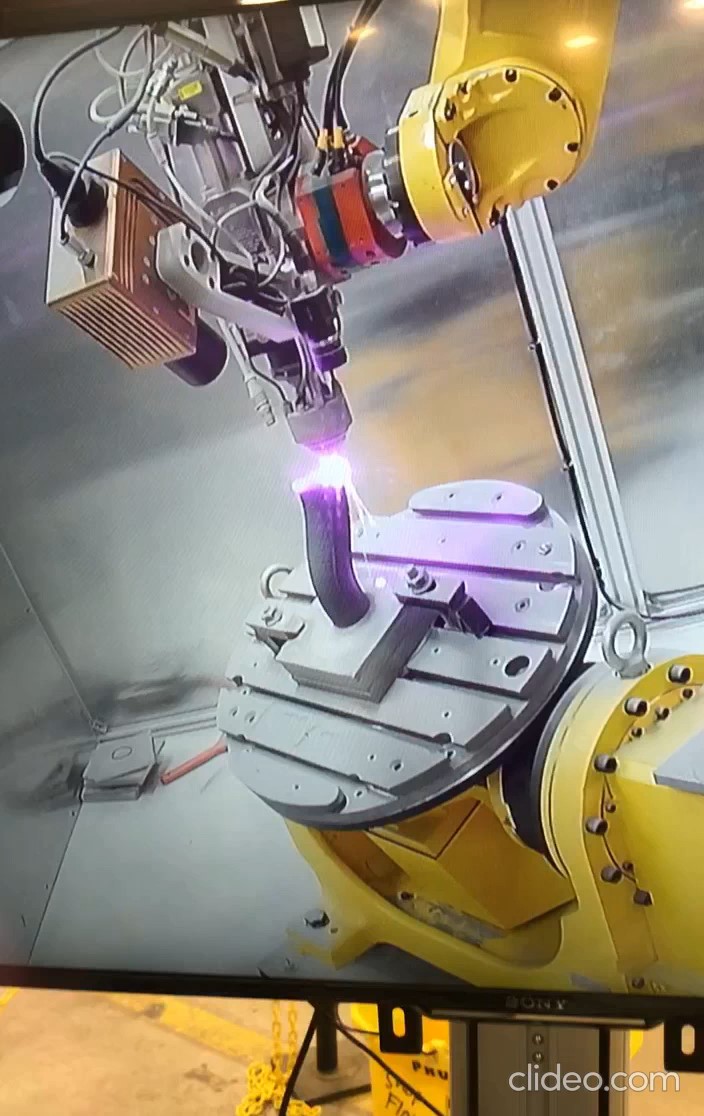

The tests of this project were conducted at the University of Waterloo in Ontario, Canada using Laser Directed Energy Deposition (LDED). By eliminating support structures, the team were able to simplify process planning and reduce waste material.

Parts with geometric overhangs, such as pipes with bends, pose a special challenge for additive processes that deposit material in horizonal layers. To deposit material in the overhang area of the bend, the process needs to incorporate support structures that allow the layers to extend beyond the pipe. This works well enough but incorporating support structures adds time and effort to production planning and creates extra waste material.

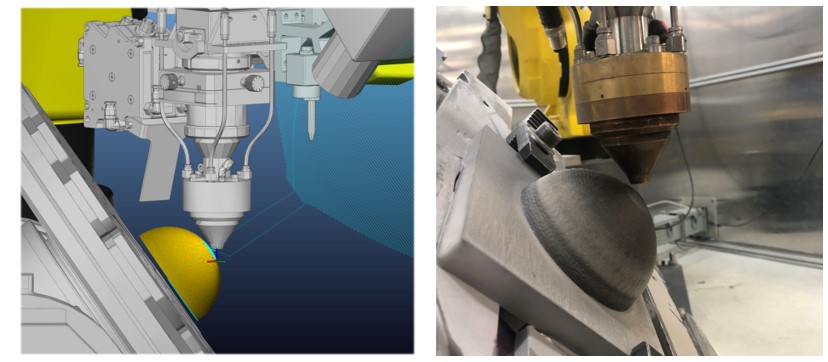

To simplify and speed up the LDED process, Promation, ModuleWorks, and MSAM teamed up to develop a new method that deposits the layers in non-horizontal planes. The printing nozzle is mounted on a 6-axis robotic arm to ensure it always remains tangent to the deposition surface which is automatically tilted using a 2-axis positioner. Applying deposition layers to a tilted surface enables pipe bends and other overhang geometries to be printed without support structures, which simplifies production planning and reduces waste material.

In the laboratory tests, the team used the new method to manufacture a pipe with a 45 degree bend with no support structures.

The new method was also used to successfully print a closed hollow dome.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com