Today, interesting announcements draw our attention regarding 3D printing in the communication sector, the aerospace and automotive industries and the fashion industries.

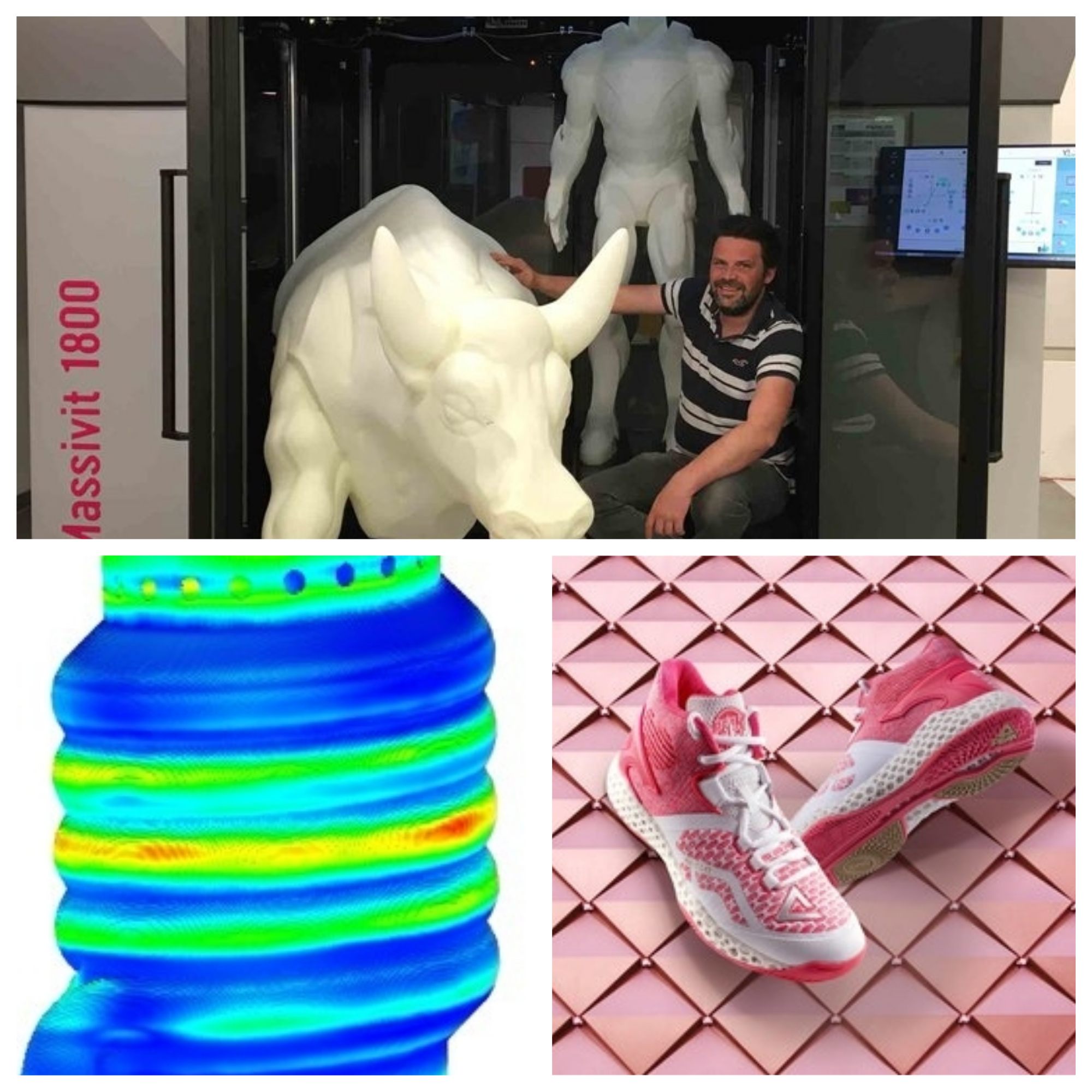

Massivit3D in Benelux

Massivit3D, provider of 3D printing solutions for the communication and visual sectors announces its arrival in Benelux. Digital Dot, supplier of technical support, consumables, software and super-wide format printers within Benelux, is the company that will be in charge with providing customers Massivit’s 3D printers.

As a reminder, Massivit offers two main products: the 3D printer Massivit 1800 whose capacities have already been proven through various examples: winter sports gear, festival’s attraction or even visual communication.

In addition to this solution, the company recently unveiled a new 3D printer: the Massivit 1500 Exploration 3D Printer, also intended for visual communication applications.

With the first Massivit 1800 available in the Benelux region via Digital Dot, the manufacturer can not only provide customers with a full on-site workflow demonstration but can also help them access the technology and discover the multitude of larger-than-life visual communication applications achievable.

Welcome Massivit!

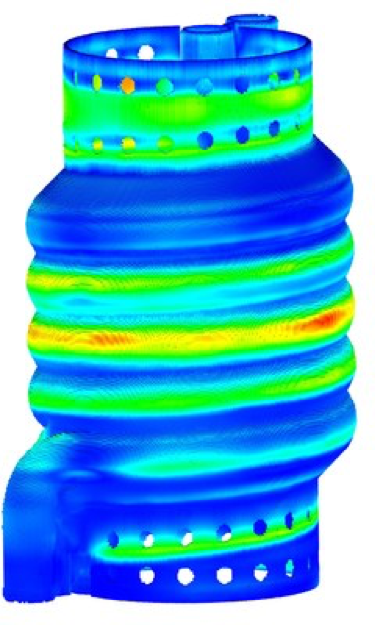

ANSYS 3D printing Solutions in the Aerospace and Defense, Biotech and Automotive Industries

To put it simply, Ansys is a software specialist, especially in Pervasive Engineering Simulation. Therefore, the software of the company plays a key role in the implementation of various activities: drive a car, touch a mobile device, wearable technology…

Today, the company offers two solutions, ANSYS® Additive Print™ and ANSYS® Additive Suite™ for metal additive manufacturing.

It is no more a secret; metal additive manufacturing is the most important market within the 3D printing world. Ansys’ solutions would enable to print lightweight complex metal parts successfully the first time and analyze microstructure properties and behavior. According to the company, customers could quickly test their product designs virtually before printing a part. Therefore, the part will be validated at the design stage before turning on the printer, which might be interesting because it reduces the cost of physical trial and error.

Users will then be able to reduce the cost of additive manufacturing by limiting design constraints, reducing waste and shrinking print time.

Peak’s first 3D printed volleyball shoes

The sports brand is always surprising with innovations. After the Future I and its 3D printed basketball boots, Peak unveils the first 3D printed volleyball shoes.

Speaking about volleyball, players of this sport know that it requires “upward momentum”, whether it’s passing, saving, serving or even spiking. Peak decided to focus on these jumping movements and after collecting data of several volleyball players and taking into consideration their needs, the manufacturer builds a new shoe using 3D printing technology.

“Through the use of SLS laser technology and a more lightweight and flexible TPU powder printed on the bottom of the shoe, Peak created superior cushioning performance. The beauty and performance of this collection of the world’s top 3D volleyball shoes announced the success of Peak in the development of volleyball sportswear.”

As Xu Zhihua, CEO said, “Innovation is the basis for Peak to go international”.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com