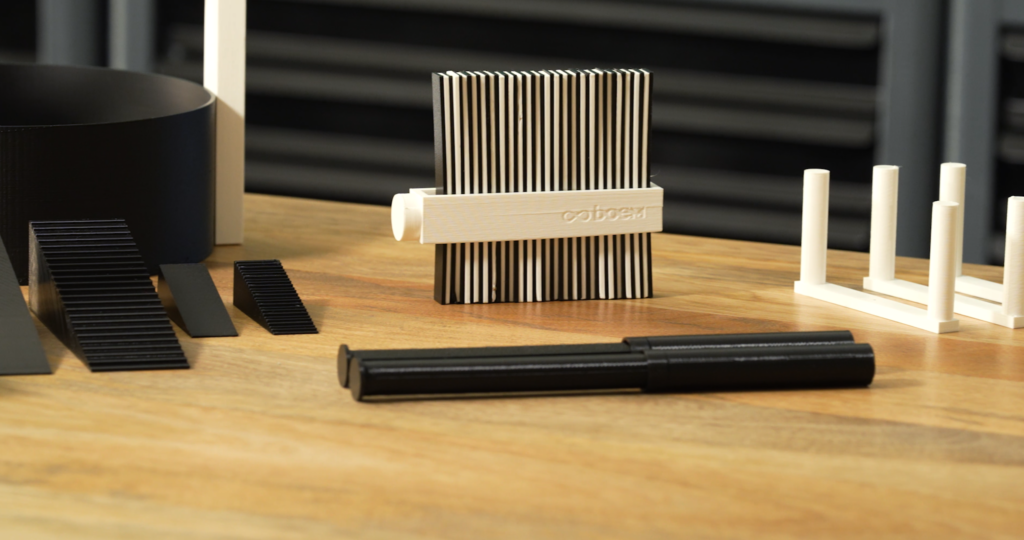

Acknowledged for providing hand tools for the makers, WIESEMANN 1893 has decided to widen the reach of its services by giving more flexibility to its customers. To do so, the Germany-based company has developed ENABLE 3D, a platform that provides customers with 100 digital designs for tool accessories.

The files can be downloaded for free and printed on a customer’s 3D printer. However, the team at ENABLE 3D can also ensure a coproduction and decentralized production approach. Furthermore, another option for those who do not have access to a 3D printer, remains to reach out to ENABLE 3D’s community printing service and submit a request. One of its community members will print out the request with their own 3D printer and send the final product to the customer, at a low cost.

One key item that was crucial to make this platform viable was prototyping – CEO and founder Siskowski and his team describe as a long and slow road.

In the past, the team at WIESEMANN 1893 and ENABLE 3D conducted such tasks through external service providers but the resulting wait times to get simple parts meant fewer options for iterations and much less creative freedom in their designs.

With long lead times and increasing costs, they turned to 3D printing. With their first 3D printer, a MakerBot METHOD X, Manuel Siskowski explains that they saw a shift in product design, where they are able to be much more creative.

“Prototyping is key for us. We focus on quality designs and try to deliver the highest quality possible. To do that, it is crucial to test a lot and iterate quickly, and the MakerBot METHOD X helps us by speeding up that process. It is a great benefit during prototyping because it increases our time to market significantly, while reducing costs”, he said.

For those who do not know, the MakerBot METHOD X is an interesting option for the wide range of production materials from ABS to nylon to carbon fiber composites it can process and its ability to use third-party materials through the MakerBot LABS GEN 2 Experimental Extruder.

“With the LABS extruder, we are very flexible with testing our own materials. With ENABLE 3D, we frequently test with recycled filament, pushing us further along the circular economy challenge. With MakerBot LABS, we are leveraging materials that we have developed in-house on METHOD X,” stated Siskowski. “Primarily, we use 3D printing for product and process quality. But we are now able to test unique materials with MakerBot. We have developed recycled filament from our product waste streams and have integrated it into METHOD’s ecosystem.”

Another benefit of using an in-house printer for the product design team was their ability to monitor and control the prints remotely with MakerBot CloudPrint. Having their own infrastructure of 3D printers to test different iterations and designs for all the WIESEMANN 1893 tools as well as other projects for customers was never more important than during COVID-19. With METHOD X and a skeleton staff on site, they were able to keep the production running even during the pandemic, the company notes.

“With ENABLE 3D, we commercialize and develop additive manufacturing use cases, and all of those use cases focus on the coproduction side of things. In those applications, we have a brand or a designer, and the production is done by the consumer,” said Siskowski. “With the WIESEMANN 1893 brand, we continue to develop different tools and products. But with all our projects, whether it is for WIESEMANN 1893 or ENABLE 3D, we are working hard to close the circular gap.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com