AMPOWER gives key tips to companies that are taking their first steps in Additive Manufacturing & insights into the current market situation

A quick Google search for “additive manufacturing/3D printing & Consultancy” reveals hundreds of companies that provide their expertise to companies that are willing to take the right first steps into additive manufacturing. These consultancy firms are either independent or are part of well-established companies. Given the intriguing and sometimes complex nature of additive manufacturing technologies, all these companies certainly have their place on the market. However, while most of them usually operate in their region, very few actually manage to have a seat on the international stage as AMPOWER does.

The Germany-based startup opened its doors three years ago, with the mission to helping companies integrate AM into their activities.

At this point, AM consultancy which is AMPOWER’s core business should not be confused with 3D printing consultancy. Indeed, while 3D printing is utilized to refer to a technology used for the creation of prototypes, AM on the other hand, lays emphasis on a more in-depth use of the technology by industrials. The term usually implies the production of consistent, quality and repeatable parts by operators.

“We saw many companies on user and supplier side struggle to find support with go to market strategies and qualification issues related to Additive Manufacturing. AMPOWER is closing the gap between technology-focused support from research institutes and high level management consultancy”, Matthias Schmidt-Lehr, Managing Partner tells 3D ADEPT Media.

At that time, companies needed to acquire a deep knowledge about Additive Manufacturing. However, the learning phase of AM usually varies from one company to another. Depending on a company’s investment in the project, it can take several years and might require expensive means. To mitigate these risks and to a certain extent, to reduce this integration time, Schmidt-Lehr and his two partners decided to rely on their experience.

The company then develops key reports and technology studies that encompass key questions companies ask themselves before leveraging AM. These reports give key insights into the various players that operate on this market and their technologies as well as key statistics on the market evolution. With the goal of filling the gap between machine manufacturers and end users, the company quickly expands its offering to reach out the main stakeholders of the supply chain:

“For Additive Manufacturing users, we offer guidance along the implementation process from technology scouting and strategy, training and design to qualification and supply chain setup. For suppliers of Additive Manufacturing systems, materials, and services, we offer market analytics, go to market strategies and support in qualification programs” Schmidt-Lehr completes.

Moreover, just like AM companies greatly rely upon collaborations to develop both their technologies and the market, it should be noted that, a consulting firm like AMPOWER is also uniquely positioned to initiate these partnerships through their technology studies.

Indeed, the company conducts 2-3 highly dedicated technology studies per year (currently Binder Jetting and HIP), and covering these topics is only possible with the support of a solid network.

Key tips to introduce AM within a company and current market situation

As we are moving forward to an Industry 4.0 era that encourages the integration of intelligent production systems and advanced information technologies, companies can easily feel overwhelmed. Added to this, AM is considered to be an essential ingredient in this new movement. This might raise several questions in the management team, questions in terms of workforce competences and even new way of working.

To those companies that are introducing AM into their activities, AMPOWER’s expert first tells that they should keep in mind that this technology is application driven. “The first step is always to learn about the variety of technologies, the potential but also limitations and match the AM technology portfolio with the internal part portfolio. It is very important to create the right mindset for new designs, but also develop a realistic understanding of cost and challenges. Internal communication is a major skill for the technology introduction. Communication towards management, but also towards engineering and production is important to create a stimulating culture”, recommends the expert.

However, with the Covid-19 pandemic, things can change. Consumers’ habits have changed. As countries have reopened part of their economies, individuals and corporations are trying to live with the Covid-19 reality and are settling into a new normal. For the manufacturing industry, efforts and concerns are directed towards other objectives: minimizing the financial impact, the effects on operations and on their workforce.

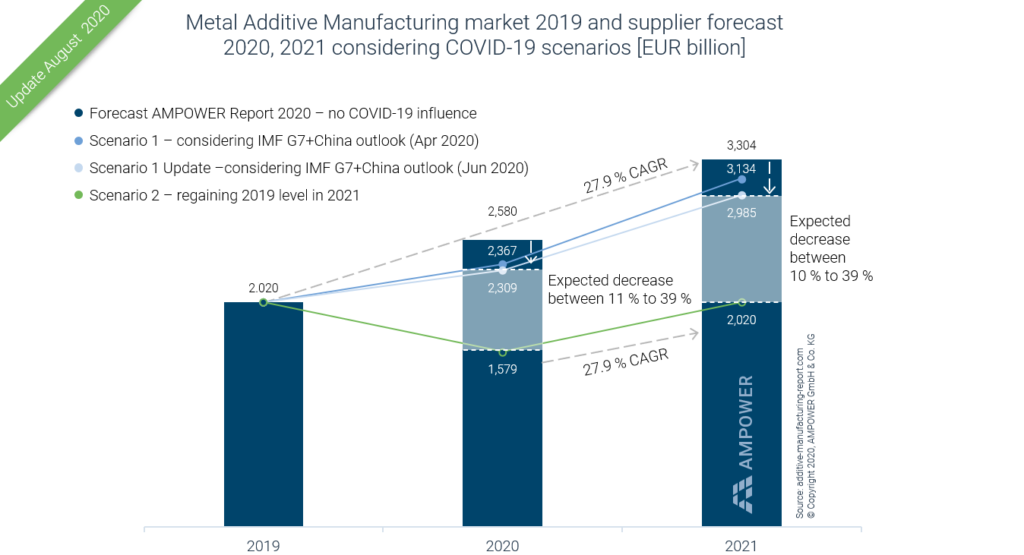

As far as the metal AM market is concerned, AMPOWER has analysed the pandemic’s impact scenarios in 2020 and realized that “the first scenario is based on transferring the expected impact from the International Monetary Fund (IMF) market forecast to the AM market. This leads to a reduced growth of the AM market in 2020. The second scenario is based on the assumption, that we will regain the 2019 market volume in 2021 and 2020 can be marked as a « lost year ». In our 2021 market report, we will find out about the actual impact. Today, we assume, that it will be somewhere between those two scenarios. The AM industry is currently in a situation, where it must prove, that it really adds value. This means that companies must evaluate, if they can earn money with AM technology. It is important, that the supply chain now focusses more on the real value proposition of AM besides nice lattice structures and bionic bottle openers. AMPOWER wants to support companies on this journey and invites everyone to join us on this path.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com