For metal 3D printing processes, production costs of a build structure are often fixed, regardless of the number of parts it contains. For a process like HP Multi Jet Fusion, print build structures can be filled with the same quantity, size and shape, or with different characteristics. Therefore, by optimizing the parts that constitute the structure, it is possible to reduce the unit production costs.

How do we ensure that?

Italian 3D printing service provider Weerg has developed a product for high volume production customers, such as professional, service and industrial customers, who can now purchase a 3D Build unit.

The 3D printing and CNC machining service providers that work with HP Multi Jet Fusion model 5210 3D printers in its facility said that the economic advantages of this system are related to the use of nesting.

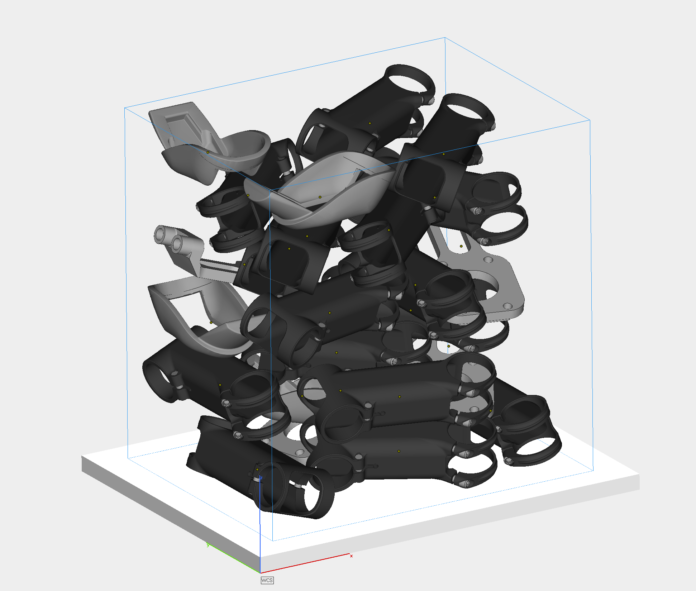

The latter facilitates the assembly of several parts by optimizing the content of the structure.

“To ensure optimal nesting, which in theory could also be done manually with a considerable expenditure of resources, we recommend the use of specialized software, among the many available on the market”, explains Matteo Rigamonti, founder of Weerg. This type of software automatically shifts and rotates a set of 3D pieces within the structure to minimize empty space and optimize the quality and quantity of the printed parts. The user can also use the software to specify the number of parts and the minimum distance between individual parts.

“The highest benefits are achieved when nesting is used to fill the full capacity of the Build 3D”, continues Rigamonti. The 3D Build technique proposed by Weerg allows 3D printing with HP MJF technology in three different materials: Nylon PA11, Nylon PA12 and polypropylene. “Since its recent launch, this new service has raised particular interest among companies that need to produce quantities in excess of their production capacity by outsourcing surplus, or that are dealing with momentary overwork or machine downtime”, says Rigamonti. “The success of this formula also derives from the extreme ease with which customers can perform nesting, sending us the 3D file of the structure with the guarantee that delivery will be made within 3 working days”.

For those who may not know, the term “nesting” comes from the English “to nest”, which means to interlock and indicates an organizational technique designed to make production more efficient through the virtual pre-positioning of elements, which are interlocked with each other as in nests. To date, Weerg states that its 3D Build service uses HP MJF technology, which guarantees industrial performance in terms of quality, productivity, and delivery times.

“To develop this service, our R&D department carried out many simulations”, explains Rigamonti. “If users who buy the structure take advantage of its full capacity through optimal nesting, they can benefit from savings of up to 60% compared to what they would have spent on producing the parts individually”.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com