Knitting machines have always been known as devices that can create knitted products in a semi or fully automated fashion. As technology evolves, techniques of improvements of this device show that a computational approach can transform 3D meshes created by standard modeling programs into instructions for a computer-controlled knitting machine.

So, thanks to Carnegie Mellon University researchers, it is possible to turn digital 3D models into knitted objects. The technology is in fact a software program that requires a computer-controlled knitting machine, that would create all types of customized 3D printed toys.

This software can make you think at Kniterate, the computerized knitting machine that enables its users to automatically transform their digital designs into knitted clothing. An innovation that combines both 3D printing and domestic knitting machines from the 1980s.

Back to our concept…

According to researchers, their method enables novice users to fabricate 3D surfaces on an industrial weft knitting machine.

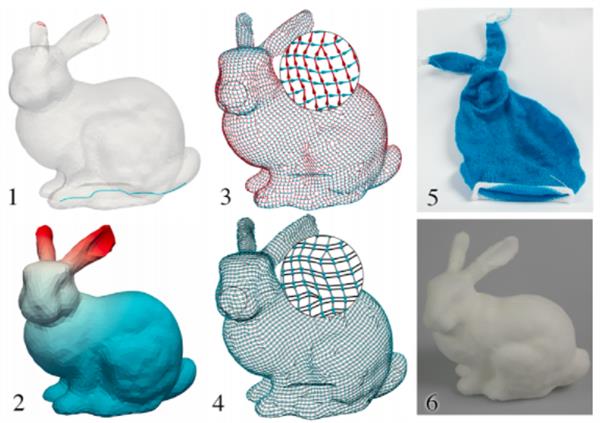

Their software can distinguish problems that the knitting device might encounter with the design based on the models’ mesh. Users can therefore avoid failed knits or potential jams with the knitting machine.

After generating knitting patterns, the latter are thereafter sent to a computer-controlled knitting machine which creates a knit “skin” of the object. Users can fill the knitted object in order to obtain the expected 3D form.

The creators of this software affirm the technology can be used to create traditional plush toys (example: teddy bears).

“Knitting machines are as robust and repeatable as 3D printers, but—until now—they have not enjoyed the same popularity,” we can read in the research paper. “We believe this deficiency stems from the lack of easy-to-use software and consumer-level hardware…This paper provides an important addition to the software landscape. By automatically producing machine knitting instructions from 3D models, our system makes these machines as easy to control as 3D printers.”

For further information, follow us on our social media and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

[dg new_window=”true” columns=”3″ attachment_pg=”false” paginate=”true” ids=”10947,10004″]

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});