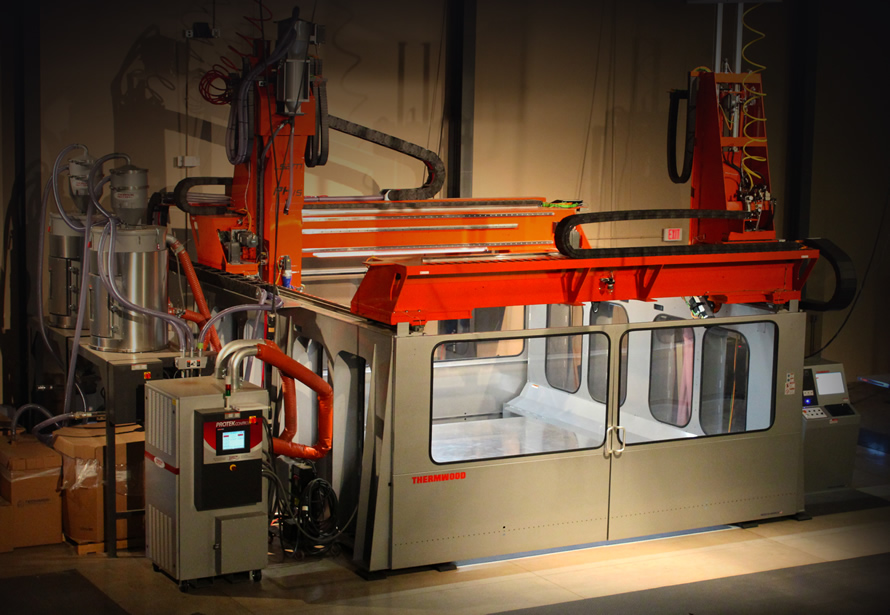

It’s a one-ton machine and a half-toolhead that Thermwood updated. In addition, thanks to a CNC milling toolhead, one can perceive a hybrid approach to the building of two gantries.

Its use

Called LSAM, the build volume of this machine is 10 ft x 5 ft x 100 ft. With a speed of 5 feet per second for the toolhead, it is designed to build large parts from thermoplastic materials.

LSAM machines could manufacture “industrial tooling, masters, patterns, molds and production fixtures for a variety of industries including aerospace, automotive, foundry and boating.”

LSAM machines could manufacture “industrial tooling, masters, patterns, molds and production fixtures for a variety of industries including aerospace, automotive, foundry and boating.”

3D printing in advanced materials

The company explains it has already 3D printed “composite tooling masters from 20% Carbon Fiber filled ABS, and has printed actual autoclave tooling from both 50% Carbon fiber filled PPS and 20% Carbon Fiber filled Ultem using this print head.”

The truth is that combining 3D printing and thermoplastics very often involves high temperatures and this goes for the build plate as well as the extruder.

The LSAM then changes the deal with its cooling process hence the thermographic monitoring system to monitor the temperature of the printed parts and allow a better control of the fans.

A partnership already signed with the US Marines Corps will allow people to discover the machine’s potential very soon.