With the increasing number of small satellites launches that are popping up, one starts to understand the crucial role of additive manufacturing in the future of human space travel. With the goal to further advance this field of application, organizations and research institutes keep exploring new applications in the field.

In this vein, researchers from MIT have developed an entirely 3D printed nanosatellite thruster by combining 3D printing and hydrothermal growth of zinc oxide nanowires. Interestingly, unlike other thrusters, this one would produce pure ions from the ionic liquids used to generate propulsion.

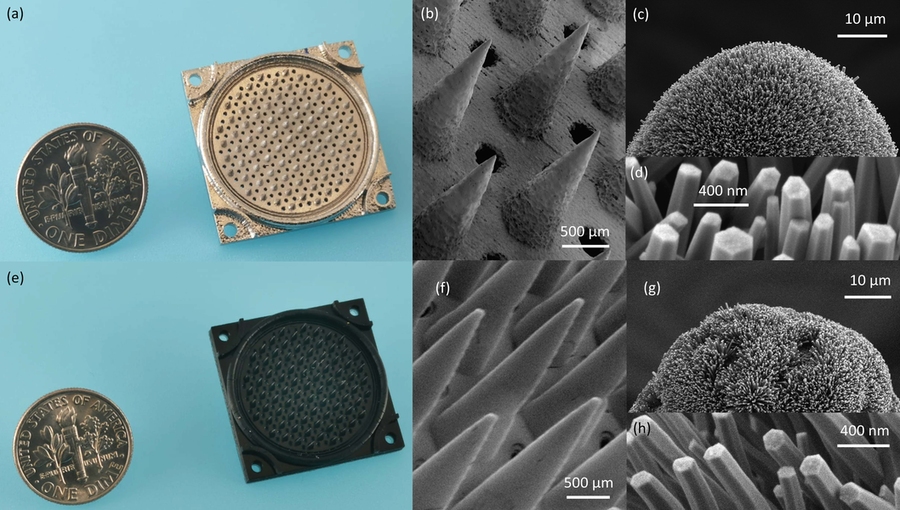

According to Luis Fernando Velásquez-García, principal research scientist at MIT’s Microsystems Technology Laboratories (MTL), “the pure ions make the thruster more efficient than similar state-of-the-art devices, giving it more thrust per unit flow of propellant. The thrust provided by the device, which is about the size of a dime, is minuscule. The force can be measured on the scale of a few tens of micronewtons, a thrust about equal to half the weight of one of the sesame seeds in a hamburger bun. But in the frictionless environment of orbit, a CubeSat or similarly small satellite could use these tiny thrusts to accelerate or maneuver with fine control.”

How does it operate?

The miniaturized thruster operates electrohydrodynamically, producing a fine spray of accelerated, charged particles that are emitted to produce a propulsive force. The particles come from a sort of liquid salt called ionic liquid.

In the MIT design, a 3D-printed body holds a reservoir of ionic liquid along with a miniature forest of emitter cones coated with zinc oxide nanowires hydrothermally grown on the cone surfaces. The nanowires act as wicks to transport the liquid from the reservoir to the emitter tips. By applying a voltage between the emitters and a 3D-printed extractor electrode, charged particles are ejected from the emitter tips. The researchers experimented with printing the emitters in a type of stainless steel as well as a polymer resin.

The researchers were able to detect the pure ion jet using a technique called mass spectrometry, which can identify the composition of particles based on their molecular mass. Typically, an electrospray produced from ionic liquids would contain ions plus other species made of ions mixed with neutral molecules.

The pure ion jet was a surprise, and the research team still isn’t entirely sure how it was produced, although Velásquez-García and his colleagues think the zinc oxide nanowires “are the secret sauce,” he says. “We believe it has something to do with the way the charge is injected and the way the fluid interacts with the wire material as it transports the fluid to the emission sites.”

Producing a jet of pure ions means that the thruster can utilize more efficiently the propellant on board, and propellant efficiency is key for objects in orbit because refueling satellites is rarely an option, he explains. “The hardware that you put into space, you want to get many, many years of use out of that, so I think it’s a good strategy to do it efficiently.”

Electrospray designs can have many applications beyond space, says Velásquez-García. The technique “can emit not just ions, but also things like nanofibers and droplets. You could use the fibers to make filters, or electrodes for energy storage, or use the droplets to purify seawater by removing brine. You could also use electrospray designs in a combustor, to atomize fuel into very small and fine droplets.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com