It doesn’t feel altogether too long since TCT 3Sixty closed its doors last year, and that’s because it hasn’t been; 2021’s show took place in September, and this year, the show was held from June 8th to 9th at Birmingham’s National Exhibition Centre (NEC). One would be forgiven for thinking that a 9-month space between shows would mean there wasn’t enough to talk about, but that certainly wasn’t the case and from approaching, it was clear, it was back in 2022 with a bang.

Boasting over 150 exhibitors and over 70 speakers across three stages, TCT 3Sixty’s atmosphere was buzzing with spaces for forums, booths for exhibitions and displays across the hall.

Throughout the show, exhibitors and attendees told 3D Adept Media how surprised they were to see such large volumes of attendees, even comparing the size of the crowd to 2021’s event which still drew in reasonable numbers. This theme of cautious optimism continued as the crowds grew; if the buzz at TCT 3sixty is anything to go by, the next 12 months look extremely promising for the additive manufacturing industry in the UK and beyond.

The demographic

Touted as an event in which businesses could attend to help “discover their additive manufacturing strategy”, the makeup of exhibitors was varied. Resellers and distributors were the first to make contact, with eye-catching displays from official resellers such as Additive X and SYS Systems Limited, who proudly displayed all five 3D Printing technologies Stratasys offers, including the latest Origin One and demonstrating the accuracy of the outputs that can be achieved with its Programmable PhotoPolymerization technology.

Also exhibiting were a number of suppliers to the additive industry; BOC exhibited their cleaner, fastest gases, JTT Cleaning Machinery showcased their mobile 3D Printer cleaners and Quill Vogue displayed their range of 3D post processing systems designed to rapidly remove a range of support material from 3D printed objects.

Manufacturers took up stage in the central part of the hall, with up-and coming brands such as Dyze Design and Construct 3D exhibiting as well as established brands such as Caracol, CDG and Voxeljet, whose high-speed sintering (HSS) technology display of serial polymer and large-scale metal casting solutions drew attention.

Despite Rapid News Group (owners of TCT Group) Chief Executive, Duncan Wood emphasising the critical point the additive manufacturing industry is at in the UK, projected to be worth £3.5 billion by 2025, 3D Adept Media were pleasantly surprised to learn that the majority of exhibitors and companies involved in TCT3Sixty were international businesses, trading and operating in countries across the world.

Key Themes

Metal 3D printing generally was a talking point throughout the event, and Dr Mark Prince of Aston University kicked off the event with a keynote on how to bring additive manufacturing to work, nicely setting the general tone for the event. Part of this, Prince said, was a need to focus on materials, questioning whether the industry truly requires innovation in the metal area at all considering the sheer strength, cost and agility of materials already accessible.

Despite this, numerous attendees told 3D Adept Media that the amount of metal 3D printer manufacturer in the room and on the various stages was refreshing to see and a clear indication of growth in the industry.

Xerox Elem Additive showcased their proprietary liquid metal printing technology and compared and contrasted their liquid metal vs powder bed fusion on the Introducing stage.

As if to confirm the continued interest in metal 3D printing, WAAM3D officially launched its RoboWAAM metal 3D printing platform at the event, promising to take ‘the production of large format 3D metal additive printing to the next level.’

The Digital Warehouse

Software and tech companies were in full force at TCT3sixty and 3D Adept Media had the chance to hear from and talk with a number of industry experts in this area.

Nicholas Parry, Head of Projects at Authentise (data-driven workflow management system business), summarised this perfectly in a panel delivered on the Introducing stage, "The role of software and automation for quality assurance in additive manufacturing goes beyond simply integrating toolsets, to include all the relevant, practical, processes activities and people that impact what goes out the door."

Materialise, long-standing manufacturing and provider of innovative software solutions, who boast the biggest 3D printing facility in Europe, made it very clear to 3D Adept Media that the future of the additive manufacturing industry lies within unlocking the full potential of the digital warehouse.

Not only does this have the added benefit of supporting businesses achieve their sustainability targets, the digital warehouse can relieve increasing pressure on the supply chain, saving time and money spent shipping parts around the world. The key to moving forward, Materialise says, is through education – a recurring theme from indeed, the majority of exhibitors and speakers.

The supply chain, the recent disruption and how additive manufacturing can help to bridge the gap was another regularly discussed topic, especially in the TCT Global Perspectives session on the North Stage.

Todd Grimm, T.A. Grimm & Associates, Inc gathered three perspectives from across the world in this forum session, moderating views from the audience and panel of experts: Dr.-Ing. Wilderich Heising, of Boston Consulting, Pantea Khanshaghaghi of Equinor and Jennifer Johns, Reader in International Business at the University of Bristol.

Transformation was highlighted in this session, with businesses asking experts if they could pinpoint the correct time to transform their business and adopt AM. The response from the panel of experts was that generally, there is a crisis point that acts as a catalyst for the transformation, such as the supply chain disruption, but it’s now time to find out if your competitors are utilising the latest technologies and catch up.

In this session, Khanshaghaghi (that you may have already read in this feature about Equinor’s Additive Mindset) listed the three c’s of additive manufacturing; customer, competency and competition. With a renewed focus on these things, the industry can thrive. Johns focused on the role of AM in the economy, encouraging a focus on resilience and sustainability. Heising encouraged the AM industry to concentrate on value and work out how to connect the dots and major players of the industry in order to unlock its full potential. All three, reiterate the opportunities for 3D printing to overcome supply chain challenges.

Focus on Education

One interesting theme that ran throughout the whole TCT3Sixty event was the importance of education in the successful levelling up of the additive manufacturing industry.

Generally, the event was geared towards businesses and organisations, encouraging them to implement their own AM strategy. In forums and keynotes across the two days, a genuine commitment to training, up-skilling and the development of employees was repeatedly and widely recognised as a priority, with lack of technical competency generally regarded as one of the top three blockers in the advancement of the industry.

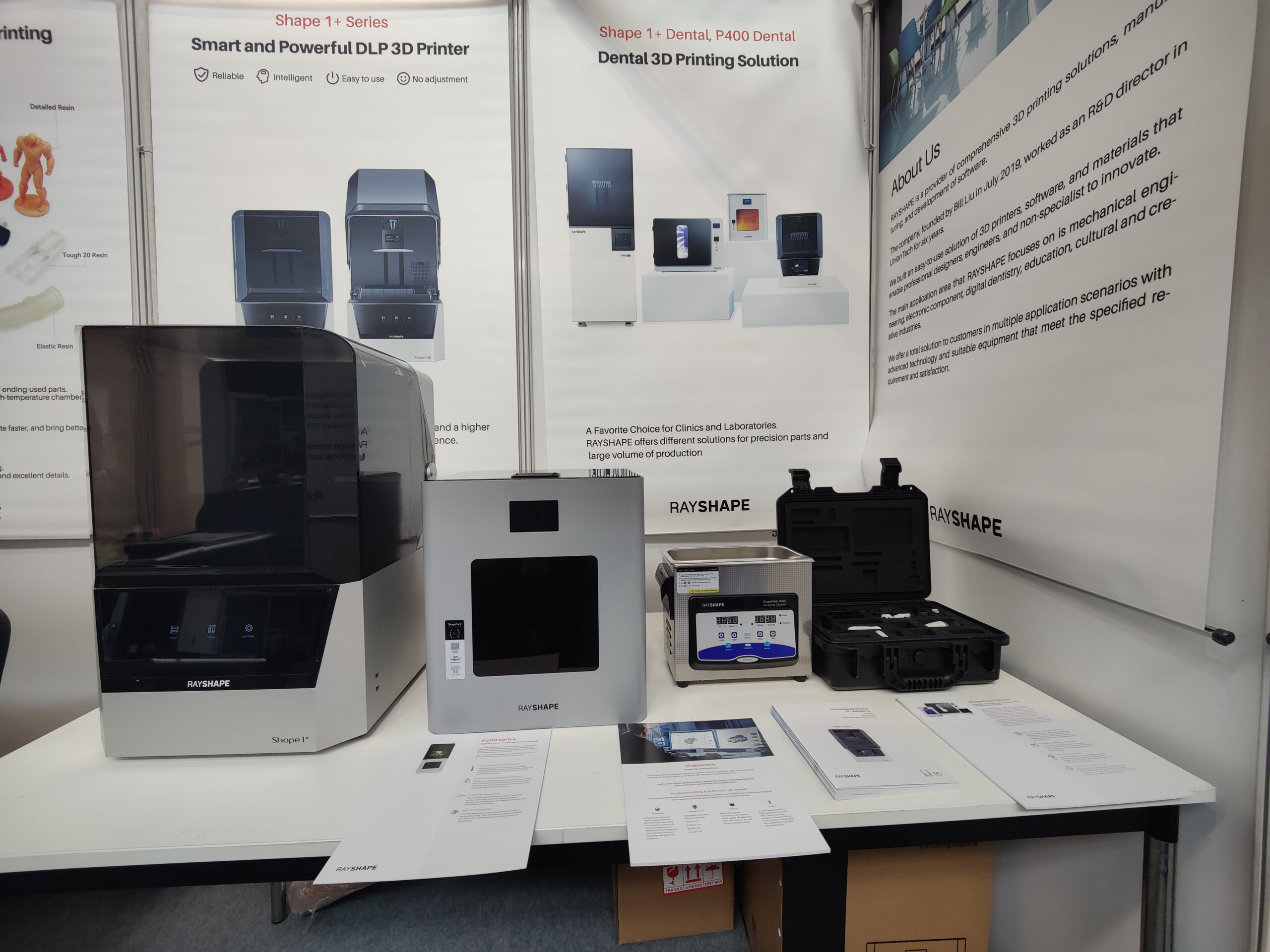

The medical and orthodontic industries were at the heart of AM players’ concerns, with RAYSHAPE introducing their professional and industrial-grade 3D printer solutions for the dental industry. Interestingly, RAYSHAPE talked to 3D Adept Media about their online university, dedicated to educating dental labs on how to achieve the best quality in the shortest amount of time.

4D Biomaterials’ exhibition stand was a constant flurry of activity, as they showcased their 4DEGRA material which would enable interesting medical 3D printing applications such as implantable medical devices. It enables controlled degradation, which means nothing harmful is left behind in the body. Available in standardised and bespoke ‘Technical Grades’ (T series), the resin-ink can already be used in research and development projects.

Perhaps even more noteworthy were the number of educational institutions and providers present at this year’s event, with exhibitors commenting on how many universities, secondary and even primary schools in attendance.

Some interesting educational attendees included:

- Aston University’s Advanced Prototyping Facility (APF) that seeks to assist businesses improve awareness of the opportunities available through 3D Printing.

- The ATSM Additive Manufacturing Center of Excellence, established to conduct strategic research and development and advance AM standards by offering training, proficiency testing and certification.

- The CREATE Education Project, committed to supporting educators, educational institutions, outreach and community programmes to use and embed technologies easily.

- The University of Central Lancashire, which offers employment-focussed manufacturing courses in manufacturing engineering and additive manufacturing, using their state-of-the-art manufacturing Engineering Innovation Centre displayed their drone printer.

Long-term attendees of the TCT3sixty will know that TCT’s commitment to education is nothing new; this year TCT’s Inspired Minds returned for the first time since the pandemic. In collaboration with The CREATE Education Project, TCT Inspired Minds works to provide students access to a variety of technologies and training relating to additive manufacturing (AM). This year almost 100 students attended the event and spent time learning in a classroom within the show. They took part in 3D printing workshops and got the opportunity to be inspired into STEAM careers by gaining insight from industry experts.

Although education is always a key theme in any exhibition, let alone TCT events, the scale of representation and interest in education, training and certification this year created a buzz around the hall, with a number of exhibitors telling 3D Adept Media it was a promising sign that the UK’s interest and enthusiasm for the additive manufacturing industry is finally catching fire.