Remember Supernova – the company that debuted on the AM market at the beginning of this year with the goal of accelerating the development and commercialization of its Viscous Lithography Manufacturing (VLM) solution?

It has announced the establishment of a business unit that will focus on 3D printing of energetic materials. Named Supernova Defense & Space, the business unit aims to enhance the capabilities of parts in critical applications like Solid Rocket Motors (SRMs), which play a pivotal role in the development of hypersonic platforms.

Needless to say the VLM technology will be at the heart of the manufacturing process. As a reminder, the lithography-based AM process uses a transparent film to transfer high-viscosity materials onto a build platform, where they are cured by light to form 3D printed parts. Unlike conventional processes which require low-viscosity resins, VLM can handle materials with up to 100 times higher viscosity, which benefits from longer oligomer chains in the formulations, resulting in superior mechanical properties.

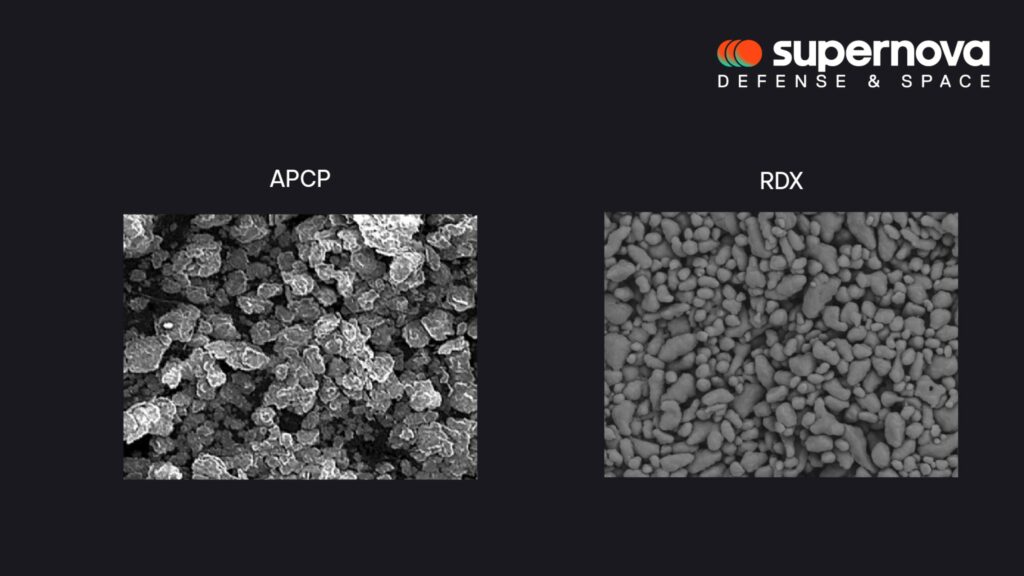

Energetic materials are compounds capable of rapidly releasing significant amounts of energy through chemical reactions, commonly used in propellants and explosives. While military-grade formulations, such as APCP (Ammonium Perchlorate Composite Propellant) and RDX (Cyclotrimethylene trinitramine), can be reliable, their formulations (which can include solid loads exceeding 80%) are not compatible with standard AM technologies. Not to mention that traditional processing techniques, ranging from casting to extrusion, impose severe geometric limitations.

The team at Supernova confirms their technology can address these limitations by processing formulations with over 88% solid load. In addition to the well-known benefits of AM, the VLM process can deliver stable and homogeneous component properties – starting from a uniform particle dispersion, with isotropic layers, and ensuring the absence of air gaps; and on-demand and on-shore production on the other hand.

The team at Supernova confirms their technology can address these limitations by processing formulations with over 88% solid load. In addition to the well-known benefits of AM, the VLM process can deliver stable and homogeneous component properties – starting from a uniform particle dispersion, with isotropic layers, and ensuring the absence of air gaps; and on-demand and on-shore production on the other hand.

The initial applications identified to benefit from these value propositions include Solid Rocket Motors (SRMs), where the goal is to enhance combustion efficiency and develop custom thrust profiles; explosives, aiming to increase detonation performance in application-specific designs such as shaped charges; and bullet grains, with the objective of achieving higher velocity and reducing weight.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com