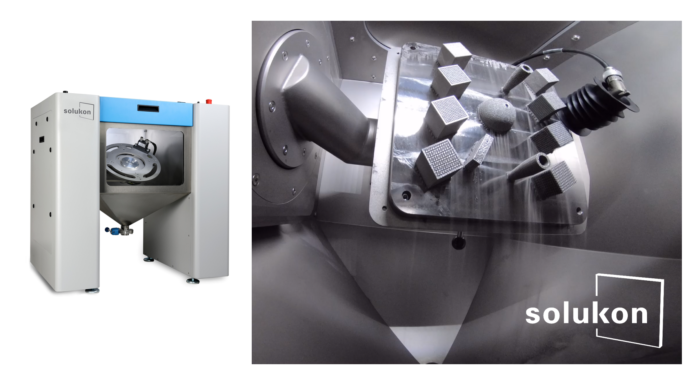

One of the most widely known automated depowdering systems developed by Solukon is the SFM-AT800S solution but let us not forget that the company also has an entry level machine that it has been improving since day one. This solution, the SFM-AT200 system is the one we saw at many industry events or even in a webinar.

Today, the company announces it has further improved the user experience of this machine, by integrating a new frequency excitation.

As a reminder, this depowdering solution is based on the company’s Smart Powder Recuperation Technology (SPR®) and enables the removal of powder by part rotation and controlled vibration in a safe & controlled atmosphere. With a small footprint, the machine fits perfectly the removal of powder for small and medium-sized metal parts. Furthermore, Solukon explains that since the process chamber can be inerted within minutes, it makes the machine a great fit for medical parts with lattice structures.

Despite these advanced features, some complex medical parts with narrow internal channels or porous structures may still retain powder residues, hence the importance of a new ultrasonic excitation.

The company explains in a press communication that electric frequency excitation in the ultrasonic range makes the powder “flowable”. As a result, it only takes a few seconds for the powder to flow out of these small channels. Add to that the rapid inertisation of the machine, the operator can obtain clean and reproducible parts with no efforts.

Results after first testing of the new frequency excitation

One of the medical companies that has been using AM technologies since its creation, including the SFM-AT200 from Solukonis the Swiss m4m Center. The Switzerland-based center isa technology transfer center that has dedicated its core business to medical 3D printing. Whenever it is possible, the company does not miss a chance to provide key insights into the way it uses AM technologies and the way these technologies impact the healthcare industry.

For the testing of this new feature in Solukon’s entry-level machine, the technology center has supplied some medical parts. In compliance with the American standard ASTMF33F, these parts feature extremely fine internal channels and cavities, making them ideal for testing frequency excitation under real conditions.

According to Nicolas Bouduban, CEO of Swiss m4m Center, “frequency excitation further shortens the already short process time of the SFM-AT200 when cleaning medical components. Now, powder flows out of lattice structures, too. Automatic depowdering with the SFM-AT200 is a real door-opener for validated postprocessing.”

Commenting on this frequency excitation, Andreas Hartmann, CEO and CTO of Solukon, states, “Solukon is keen to support MedTech with depowdering solutions. Solukon systems depowder in a standardizable and reproducible way and pave the way for holistic process chains in MedTech.” “With the new frequency excitation, we are taking another important step and can now also completely depowder particularly small openings and porous structures of medical components,” he adds.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com