One of the themes we discuss at Formnext this year is the necessity to have a technology-agnostic approach to additive manufacturing. If this approach is not emphasized by all OEMs, our conversations highlight various levels of the manufacturing value chain that can benefit from it.

Renishaw and Materialise’ collaboration shows one specific angle.

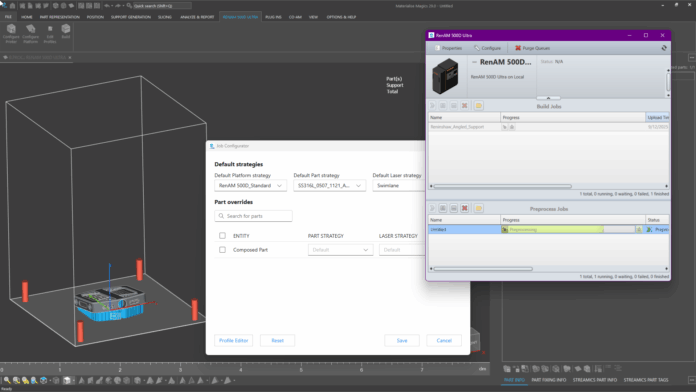

If you remember well, to increase efficiency and productivity for users of the RenAM 500 series of metal 3D printers, the 3D printer manufacturer started working with Materialise last year so that its system users can benefit from Materialise’s next-generation build processor software.

As a reminder, build processors link 3D printers with data preparation software, streamlining the additive manufacturing process from design to print.

This collaboration led to a next-generation build processor: NxG BP. This new processor enables direct export of job files from Magics to Renishaw machines using the QuantAM file format, eliminating manual file handling, reducing errors and saving valuable preparation time.

“We’ve worked closely with users to understand where the bottlenecks are in their AM workflows,” said Ben Diaz, product manager at Renishaw. “NxG BP enables swim lane laser control, integrated inspector tools, implicit modelling support and compatibility with the RenAM 500 series of machines. Ultimately, customers will have a more intuitive and efficient way to get from design to print.”

A key innovation is the Swim Lane feature, which intelligently distributes laser scanning across defined regions of the build platform. By preventing interference between lasers and managing overlap for full fusion, the system enhances part quality and consistency while reducing build times. Customers also benefit from integration with nTop implicit modelling workflows, making it easier to handle complex geometries and prepare jobs more efficiently, a press release reads.

To enhance quality assurance, NxG BP features a built-in Inspector tool that provides real-time verification of laser paths and job setup directly within the workflow. This removes the need to move between different software environments for quality checks. With this data-driven capability, users can detect and address potential issues before production starts. The processor is also fully compatible with the entire RenAM machine family, ensuring that the advantages of this new solution can be applied across Renishaw’s installed base.

We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.