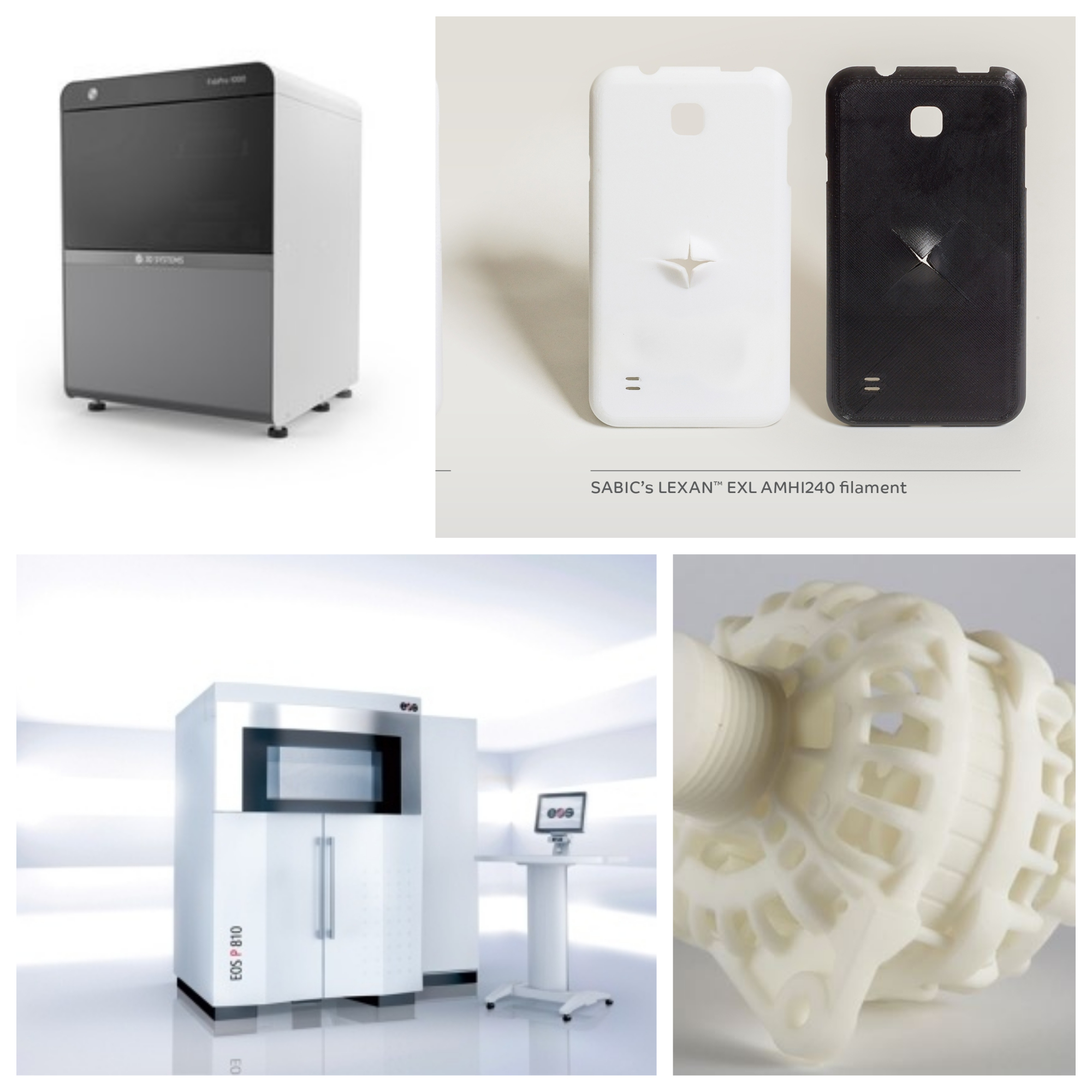

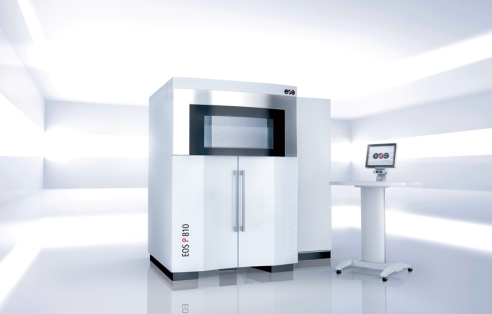

EOS P 810 polymer industrial 3D printing platform and HT-23 material

EOS has launched the new EOS P 810 polymer platform intended for the production of ALM material HT-23. The material has been launched with the help of Boeing and thanks to the fact that it is a high-temperature polymer material, it addresses industry requirements for demanding high-performance parts. Customers of the aerospace industry are those who can benefit the most from this solution.

Technically speaking, “HT-23 is the first carbon fiber-reinforced PEKK material that can be processed on EOS systems, as such offering isotropic part properties. Parts additively manufactured with this material offer high strength, low weight and are capable of withstanding high temperatures. It is the first high-performance material with a low refresh rate of 40 percent, as such also contributing substantially to reduced costs-per-part.”

During the event, visitors will also discover EOS P 810. Developed for the aerospace industry, with a build volume of 700 x 380 x 380 mm and two 70-Watt lasers, the system enables the production of large structural parts and helps its users to increase their productivity.

Roboze to add SABIC’s new polycarbonate

SABIC’s new polycarbonate filament for FFF is capable of high impact resistance and ductility at low temperatures (up to -30 ° C). Useful in the aerospace, consumer and automotive industries, the material distinguishes itself among those of the same range by the fact that it delivers up to four times better notched Izod impact at room temperature, and up to three times higher at -30°C, depending on printing orientation. It will now be available with Roboze One+ 400.

PA612-GB 3800 is ultra-high resistant to shocks and vibrations

Prodways Technologies and A. Schulman have unveiled the new PA612-GB 3800 powder. Integrating an ultra-high shock resistance, the material enables the 3D printing of parts for the transportation industry or any moving assembly such as automotive fuel tanks or all kinds of industrial pump body units.

The PA612-GB 3800 powder matrix was specially designed to withstand very high temperatures without distortion. This feature allows the development of a vast number of potential applications, specifically for the transportation industry, including train ballast systems, which need to withstand vibrations and high temperature stress caused by braking systems.

3D Systems comes back with its platform Figure 4

3D Systems will showcase its platform Figure 4. Unveiled last year, visitors can discover the parts ‘Production” and “Standalone” of the platform which highlights part print speeds up to 65mm/hr, with prototyping speeds of up to 100 mm/hr.

“The Figure 4 platform delivers part accuracy and repeatability, with Six Sigma repeatability (Cpk > 2) across all materials. The combination of speed and accuracy complemented by a light-based UV curing process that takes minutes versus hours with heat-based curing processes.”

Via the digital molding option, Figure 4 could be a complementary process to traditional methods.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com