Last year, in July, Linde and 3D Medlab announced their plan to discover how atmospheric conditions could be optimized for the production of complex lattice structures.

For those who do not know them, 3D Medlab is a medical company that designs and produces 3D printed medical devices. The company became a Marle Group company in April 2021.

Linde on the other hand, is a global industrial gases and engineering company. In the AM industry, the company has dedicated its core business to study the role of atmospheric gases for additive manufacturing and provides dedicated services to enhance the impact they have on AM processes.

To achieve their project, Linde developed a new process gas for the optimization of the additive manufacturing of medical components. In this specific case, the expert wanted to improve quality and productivity of advanced thin medical devices made from Ti64.

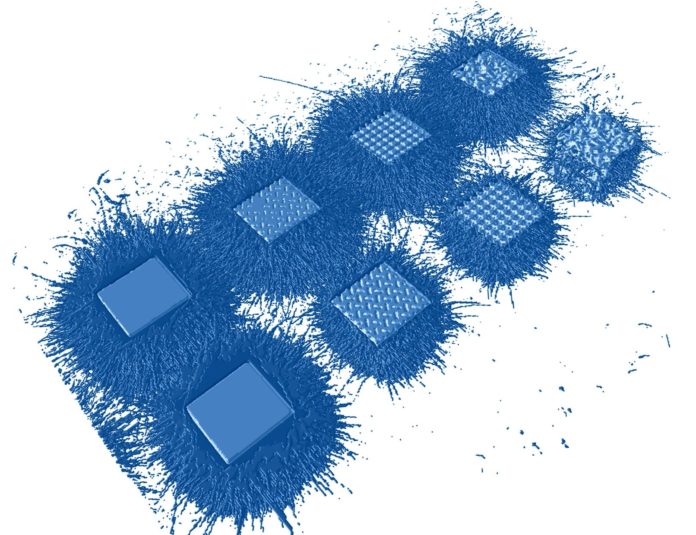

The study – undertaken between January 2020 and March 2021 – investigated the effect of the new process gas on spatter formation and process stability during laser powder bed fusion (L-PBF) of Ti64 lattice structures and their resulting properties. Process monitoring with optical tomography pictures showed that spatter emission was significantly reduced when working with argon-helium mixtures compared to argon alone. Research results have confirmed that Linde’s unique argon-helium gas mixture decreases spatter emissions by 35%, considerably reducing the risk of manufactured defective parts and improving overall surface quality.

“The ability to print reliably repeatable products is key to improving product qualification, which is crucial for the medical industry“, said Sophie Dubiez-Le Goff, Expert Powder Metallurgy for Additive Manufacturing, Linde. “Additionally, from a commercial perspective, printing time is the greatest single cost element in additive manufacturing, but this can be speeded up for thin parts by using just the right atmospheric gas mixture. Linde’s novel argon-helium mix has been developed to do just that and is a major step forward in the manufacture of titanium medical devices.”

Levels of porosity and surface quality are fundamental factors in the quality of mechanical properties of highly intricate parts, by ensuring the finished product is as close to the original design specification as possible and also that fewer metal powder parts can potentially be released into the human body.

“Porosity is the first criteria we look at in terms of defining the quality of an additive manufactured medical device“, said Gael Volpi, Head of Additive Manufacturing, Marle Group. “The results of our joint atmospheric gas study with Linde shows that the right balance of helium to argon in the process gas mixture – and ease of implementation – can make all the difference to both quality of output and productivity.“

The inert gas within the print chamber is a critical element which can affect both part quality and overall production speed, so the study was primarily aimed at assessing the ideal gas mixture to optimize both outcomes. When using argon alone, it was observed during testing that there was a significant amount of spatter – or molten metal particles caused by the laser – splashing against adjacent parts being printed. Spatter on highly intricate parts is undesirable, resulting in less fine quality of part threads. Additionally, the use of pure argon resulted in a level of porosity which Linde and 3D Medlab engineers believed could be significantly improved.

“Higher productivity was not reached at the expense of quality“, emphasized Sophie Dubiez-Le Goff. “On the contrary, thanks to the new process gas mixture being so effective in reducing porosity content by 70% – according to micro-computed tomography analyses – compression properties remained comparable to parts processed with argon only.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com