Following the investment in its fifth additive manufacturing system, Nexxt Spine is now able to share a few advancements of their activities.

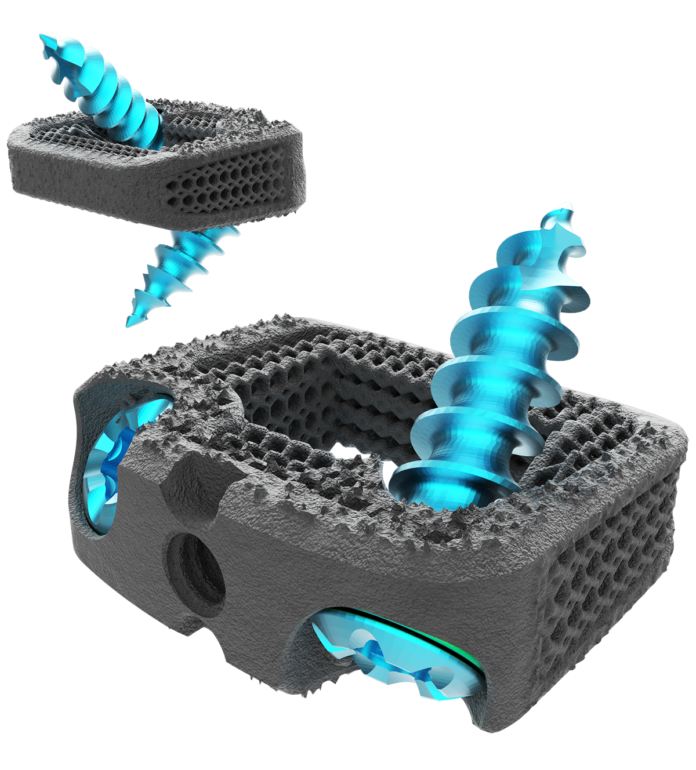

The specialist of spinal solutions has been granted FDA 510(k) clearance of the NEXXT MATRIXX® Stand Alone Cervical System. According to the company, the system encompasses the cutting-edge design and surgeon friendly precision distinct to the NEXXT MATRIXX® brand of 3D printed porous titanium interbodies using GE Additive’s Mlab printer.

The NEXXT MATRIXX® Stand Alone Cervical System

Designed to be used as an adjunct to fusion at one or two contiguous levels (C2-T1) in skeletally mature patients, the Stand-Alone Cervical System will help patients that suffer from the treatment of degenerative disc disease. It should be used with the bone screw fixation provided and requires no additional fixation.

“This enhancement of the NEXXT MATRIXX® portfolio was the next natural progression for Nexxt Spine,” states President Andy Elsbury. “With patient care always top of mind, we strive to develop end products that surgeons prefer and hardware patients can count on. Our Stand Alone Cervical is no exception and will showcase the propensity of NEXXT MATRIXX® technology to facilitate the body’s natural power of cellular healing for fortified fusion.”

The AM trend in spinal solutions

The increasing adoption of additive manufacturing into the spinal industry has enabled increased complexity of implant design and patient-specific solutions for previously unimaginable cases.

Several companies of the industry including IMR, EIT, nuVasive, Stryker, to name a few of them, have been leveraged additive manufacturing for their various solutions. All of them share common goals: optimize bone ingrowth, reduce costs and enable patient-specific solutions.

Direct metal printing being the main technology they leverage; these companies are able to take advantage of a variety of biocompatible materials including several grades of titanium and cobalt-chrome.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com