Aleph Objects adds LulzBot TAZ Workhorse 3D Printer to its portfolio

Less than 2 months ago, Aleph Objects released LulzBot TAZ Pro, a desktop 3D Printer that provides dual-material printing and can produce large functional prototypes, manufacturing aids, and print-on-demand parts.

Today, the company unveils the LulzBot TAZ Workhorse 3D Printer that introduces automatic X/Y/Z. The LulzBot TAZ Workhorse Edition boasts a 14% bigger build volume than the TAZ 6. It can process a wide range of materials, including high-heat and high-strength composite polymers thanks to its hardened-steel tool head components. With 360°cooling, the tool head delivers superior overhang and bridge performance.

The FDM 3D printer offers a build volume of 280x280x285 mm and a print volume of 22,344 cm3. Full specifications can be found here.

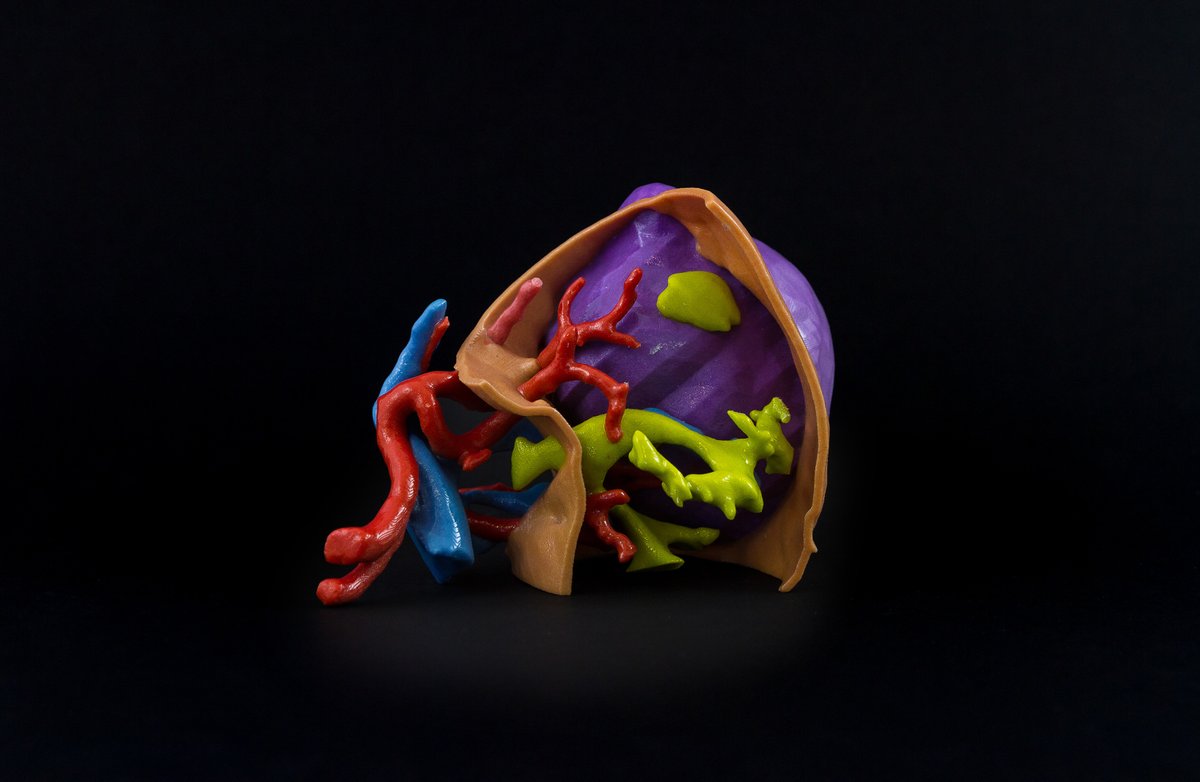

Fluidda and Materialise to improve respiratory care thanks to 3D Printing

Materialise just invested 2.5mio EUR in Fluidda, a Lung Imaging Company that uses artificial intelligence and advanced machine learning to combine low dose High-Resolution CT Scan images with advanced computer based flow simulations.

The experience of Materialise in medical 3D printing is no secret. From 3D printed footwear to 3D printed medical models, the company has made it one of its core sectors of activity. Using Materialise experience in 3D printing, both companies will develop more personalized solutions that can help the growing number of patients suffering from COPD, asthma, and other respiratory diseases.

As part of this new collaboration, Wilfried Vancraen, founder and CEO of Materialise, will join the board of directors at Fluidda.

Integrating Additive manufacturing in the existing U.S. Army supply chain

The National Center for Defense Manufacturing and Machining (NCDMM) with its National Additive Manufacturing Innovation Institute, America Makes and Catalyst Connection collaborate to launch AMNOW, a new program to support additive manufacturing (AM) technology insertion into the existing U.S. Army supply chain.

Valued at $3.7M in funding, the programme is structured as a potentially multi-phase, multi-year contract and will integrate and accelerate the dissemination, transition, and use of cutting-edge AM technologies as part of its initial phase in the U.S. Army.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com