Remember when we explained that post-processing in additive manufacturing of medical parts is a matter of liability? Well, we recently attended a webinar that confirmed again this statement, but most importantly, gave attendees further technical information about a technology that can effectively help the operator to move to other post-printing stages.

German specialist of automated depowdering systems Solukon held a webinar with The Swiss m4m Center as co-host on MedTech and Depowdering. The Switzerland-based additive manufacturing center develops medical applications that foster the development and usage of AM. With a key focus on all process know-how in a validated environment, the centre is on a mission to filling the gap between research institutions and medical companies in Switzerland. Needless to say that to achieve this mission, the center surrounds itself with key technological partners such as Solukon.

Transforming a clinical need into a validated AM solution

From the outset, Nicolas Bouduban from the Swiss m4m center, explained the complexity in turning a clinical need into a validated AM solution. Whether the need comes from a research centre, a start-up or an AM supplier, the solution that will result from this demand will only benefit a specific patient. Therefore, the manufacturing requirements will remain the same: create a safe, certified and disruptive product. Certification and disruption usually depend on the manufacturing process which is Additive Manufacturing in this case.

For Bouduban, a ‘new’ manufacturing process always requires more attention as it can add further complexities in the work of medical professionals if it is not well managed. Not to mention that, professionals always need to assess all the risks for the patient.

Taking the example of patient specific implants, the expert highlighted the increasing use of digitalization tools for the manufacture of custom-made devices. If you are a medical specialist, you certainly know that, as of the first stage, which is digital medical imaging, every step is thoroughly monitored by experts from various fields before the actual surgery and implantation of the medical device.

However, when using AM, we quickly realize that the most important stage is not the manufacturing process itself. As a matter of fact, that stage becomes quite simple when we know that the success of a manufacturing process lies in its ability to ensure both health & safety of operators as well as quality and certified end-products. And the preliminary condition to achieve that is depowdering.

Depowdering, the first stage after the manufacturing process

Depowdering is quite simple to understand. This task consists in removing the remaining powder from the printed part. What makes it hard for operators is the time they usually take to perform this operation manually.

That’s where Solukon comes into play. By bringing automation into the game, the company ensures time savings of up to 90%, contamination-free powder recovery, protection against toxic dusts & dust explosion as well as reproducible cleaning results.

With a global footprint, the German company has convinced professionals across various industries including aerospace, space, research, energy, oil & gas to name a few of them. Over the past six years, Solukon has developed four various automated powder removal systems that integrate a patented Smart Powder Recuperation SPR® technology.

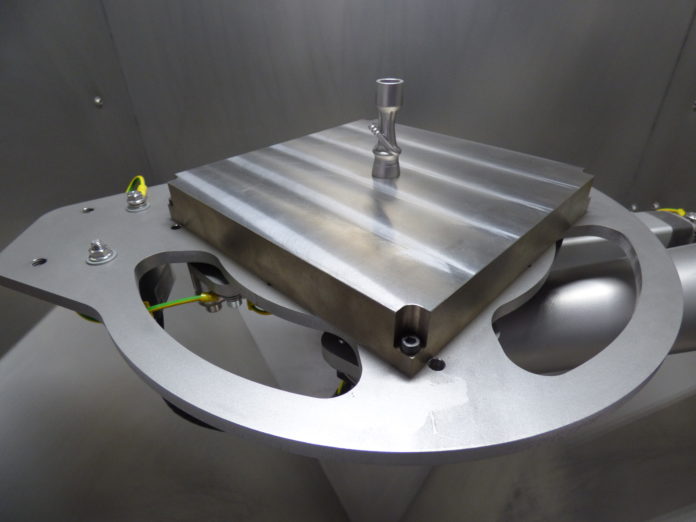

The principle is the same for all machines: the SPR® technology enables programmable pivoting of the parts around two spatial axes, in a safe way. Furthermore, systems like the SFM-AT800-S and SFM-AT1000-S can read an intelligent algorithm created by Siemens software based on digital twins. That helps move the part exactly along any 3D contour.

Speaking of the medical industry, Solukon’s CEO/CTO explained that the SFM-AT200 is very suitable for medical applications. In terms of volume, the machine fits very well the size of medical 3D printed parts. The cleaning and filter change of the machine makes it easy for the operator to carry out any material change.

“The SFM-AT200 is first very affordable. It provides a very fast insertion time (1 minute) as well as low safety gas consumption. Operators also benefit from fast loading and unloading, and there is no overengineering to save costs”, Hartmann adds.

Moreover, it should be noted that the connection between the 3D printer and Solukon’s powder removal machine could be done the same way the operator loads his machine. The CEO/CTO points out that they are on the same level as the 3D printer manufacturer.

“We can supply a bag that you put over your part inside the 3D printer. The part is then protected during the transport of the part into our machine. When mounted onto our SFM-AT300 rotating table, you close the door and can remove the bag in the safe environment of our machine”, Hartmann concludes.

This webinar gave attendees a first technical overview on “MedTech and Depowdering”. We might have placed particular emphasis on the SFM-AT200 and its fit for the medical industry but Andreas Hartmann also gave key insights into the company’s other systems. One lesson that striked us the most is that Medtech, more than most industries, is characterized by dependence on custom equipment and automated depowdering is inevitably part of it.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com