Moi Composites unveils a 3D printed fiberglass boat at Genova Boat Show. Moi Composites is an Italian start-up that is on a mission to 3D printing custom, powerful products using robots and advanced composite materials.

One of the company’s key projects is MAMBO. Short for Motor Additive Manufacturing Boat, this project illustrates the use of continuous fiberglass thermoset material in the manufacture of a boat.

With fittings and a sleek, shiny coat of paint in snapper rocks blue color, MAMBO features a unique shaped boat that cannot be achieved with traditional manufacturing.

To manufacture the boat, the Italian start-up used a patented 3D printing technology, Continuous Fiber Manufacturing (CFM). The system requires the use of robots guided by generative algorithms, and allows for 3D printing continuous fiber composite materials.

Such materials enable the fabrication of products with optimized performance and mechanical characteristics comparable to those of unidirectional fiberglass, without the aid of models, molds and other tooling equipment. In a nutshell, the cost-effective manufacturing of end-use products in small batches or unique pieces.

MAMBO, genesis and specifications

The MAMBO project required a team of global experts in automation, composite materials, and the nautical industry. Those engineers come from Autodesk, Catmarine, Confindustria Nautica, Mercury Marine, MICAD, Osculati, and Owens Corning.

“We participated in the Genoa boat show in 2017, and it was during this event that we came up with the idea of making MAMBO. We saw the project take shape first, then brought it to life, and finally MAMBO arrived today at the sea. We have 3D printed a boat, enhancing the concept of customization with a one-of-a-kind design created and tailored from the owner’s mind, to give everyone the opportunity to understand and experience the sea in their own way. All this would not have happened without the support of our partners, who believed with us in this ambitious project.” says Gabriele Natale, CEO & Co-founder of Moi Composites.

MAMBO spans 6.5 meters long by 2.5 meters wide, has a dry weight of approximately 800 kg, and is equipped with a real navigation system, cork flooring, white leather seats as well as 115 cv engine.

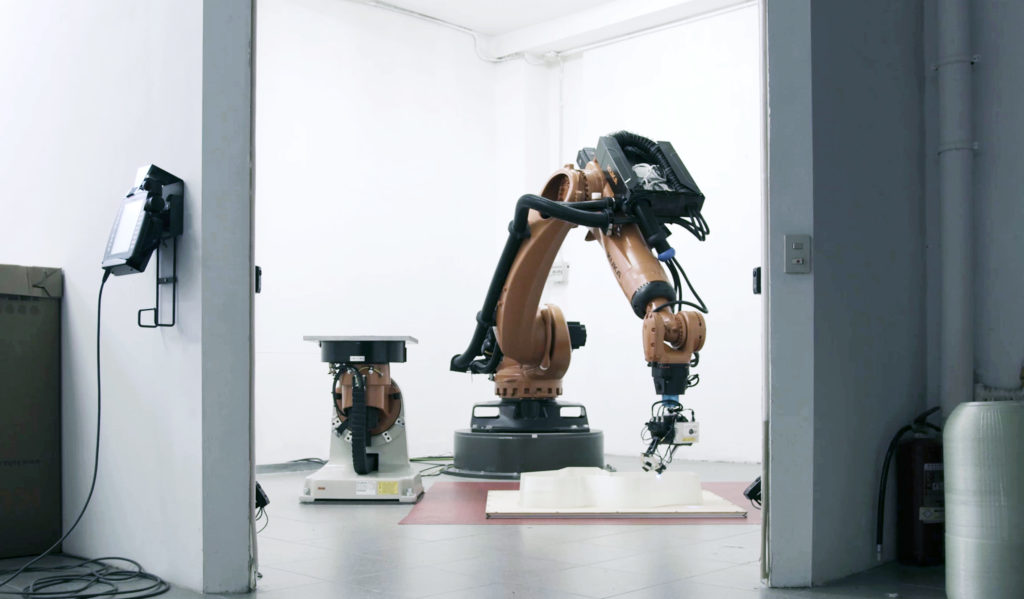

The new jewel portrays what’s possible when it comes to reinventing design and production innovation of boats. The MOI Composites team used two KUKA Quantec High Accuracy robots in Milan for the printing of the hull’s various sections. They combined this stage with the creation of a one-piece sandwich structure.

According to the Moi Composites team, the tireless and uninterrupted work of the robots combined with the wise and passionate skill of the craftsmen of the yard have given life to a hybrid and new industrial system, as technological and digital as analog and tailored, which today enables the impossible to become possible.

From yacht to autonomous “roboats”, there is still a large potential to explore for sea vehicles.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com