“Professional users adopting 3D printing are not looking for a new hobby, they’re looking for solutions to their most pressing business problems”, Kevin Han.

Fused Fabrication Filament (FFF), Fused Deposition Modeling (FDM), Fused Laser Manufacturing…the polymer material additive manufacturing technology has been given various names by manufacturers that wanted to distinguish themselves among others of the same range. Even though the most well-known name remains FDM, all of these technologies all share the same principle: the creation of a model using layer-by-layer deposition of a feedstock plastic filament material extruded through a nozzle.

Over time, we saw the emergence of various companies delivering polymer additive manufacturing technology. Scott and Lisa Crump may have invented this technology that has made and still makes the success of Stratasys but the growing segmentation of the market led to the development of the technology across several industries. How has this technology really evolved – at the technical and manufacturing levels, and more importantly, are there any other improvements we can expect? That’s the million-dollar question we will discuss in this segment – with contributions from AON3D and INTAMSYS, FDM 3D Printer manufacturers. Kevin Han, CEO of AON3D and Charles Han, CEO of INTAMSYS are the spokesperson that will share their expertise in this paper.

The FDM 3D Printing technology is much more than the simple layer-by-layer deposition of a feedstock plastic filament material. Manufacturers that decided to enter this market segment have improved this technology and raised the interest of segments that one did not expect from the beginning. What could be these improvements? This article aims to highlight these advancements in order to help professionals to decide if it’s (still) a good choice for them.

First, FDM 3D Printing can be leveraged via a Desktop FDM 3D Printer or in an Industrial 3D Printing system. As a reminder, several features might enable to distinguish a professional 3D printer from an industrial 3D printer. They include part accuracy, (high-performance) materials, typical layer thickness, build envelope as well as production capabilities (temperature, etc.) to name a few of them.

Apart from “materials”, all these features can be linked to the machine capabilities.

Improvements made with regards to machine capabilities

It was easier to attribute the use of Desktop 3D Printers to makers and the use of industrial 3D printers to big companies. Actually, SMEs and big companies can leverage both types of 3D Printers in their R&D or production department.

The choice for one or the other might vary from one company to another but their interest in both systems has given another reason to manufacturers to improve the capabilities of their machines.

It goes without saying that, the vision of a company and the way it evolves within the market, its objectives, are factors that will always have an influence on the advancements of the technology a company develops.

Going back to the roots, one major feature that enabled a drastic improvement of the field was the improvement of the filament feeding mechanism and its extruder.

After sending your file to the 3D Printer – and obviously after loading the filament in the 3D Printer, the print head starts to move but nothing comes out. Beginners sometimes easily think that their 3D printer is broken – especially those who have 3D printers with reels hidden. It turns out that sometimes, the issue might be with the nozzle or the filament mechanism.

Several causes might explain this issue: the nozzle is just too close to the bed and you have to adjust it, the user has forgotten a tiny piece of filament in the nozzle when replacing spools in which case he just needs to clean the nozzle with a needle; it might be linked to the parameters that have not well been set up or simply to the feeding filament mechanism and the extruder that have not been well fabricated.

Printing speed and printing precision are the next features on the list. They remain key features that can be improved. INTAMSYS CEO, Charles Han explains that “printing speed helps to increase the production volume and thus to reduce cost, while printing precision improvement enables 3D printing applications to expand to more demanding industrial applications.”

For AON3D’s CEO & Founder Kevin Han on the other hand, improvements can go beyond printing speed and printing precision:

“Whatever it takes to improve repeatability, reliability, and process control – and this will be accomplished through a combination of both hardware and software. There’s a lot of hubbub right now over factors such as size and speed, but sophisticated users understand that without the foundation of repeatability, reliability, and control in place, the only thing a bigger or faster solution will do is create more scrap faster.

We’re approaching this challenge from multiple angles. Preventing variability from occurring in the first place with improved hardware, monitoring the build process with both hardware and software, and enabling continuous improvement to prevent future errors from repeating with data and software.”

In other terms, it becomes “a must” to look at the combination of several characteristics that play a key role in the printing process and not just machine capabilities.

Improvements with regards to the mechanical properties of the 3D printed part

The more the market advances, the more industrials set the bar high for industrial FDM 3D Printing. The challenge is even more significant as there are now several 3D Printing technologies that claim to achieve the “impossible”. Therefore, the new standards imply that the improvements are no longer just about machine capabilities, they also concern the mechanical properties of the parts.

That’s why, “3D printer manufacturers – material producers” partnerships have become so crucial to help the industry move forward that they raise one question: how is this expectation going to change the market?

“It’s not just having access to high-performance polymers; it’s having access to the right high-performance polymers for the job at hand. If you break it down, every manufactured component can be described as a combination of three fundamental elements: Design + Material + Process. By limiting the availability of materials, the types of components that can be built are also limited”, comments Kevin Han.

Indeed, industrial FDM 3D Printing requires engineered-grade plastics (ABS, polycarbonate (PC) or Ultem), which are usually fabricated with certain additives that alter their properties so that they fit certain industrial requirements such as high impact strength, thermal stability, chemical resistance and biocompatibility. That’s why, some 3D Printed products manufactured with engineered-grade materials deliver material properties that are similar to injection-moulded parts – and are “ready-to-be used”.

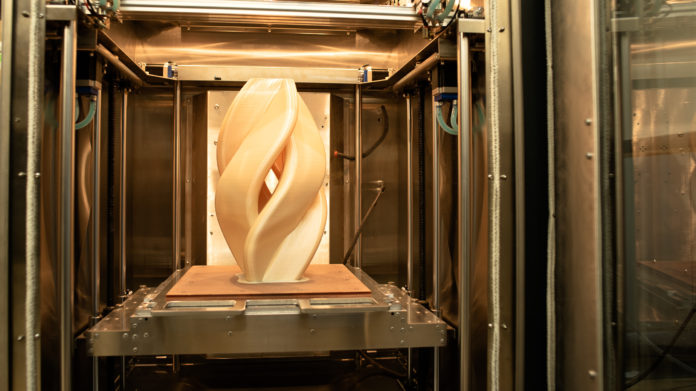

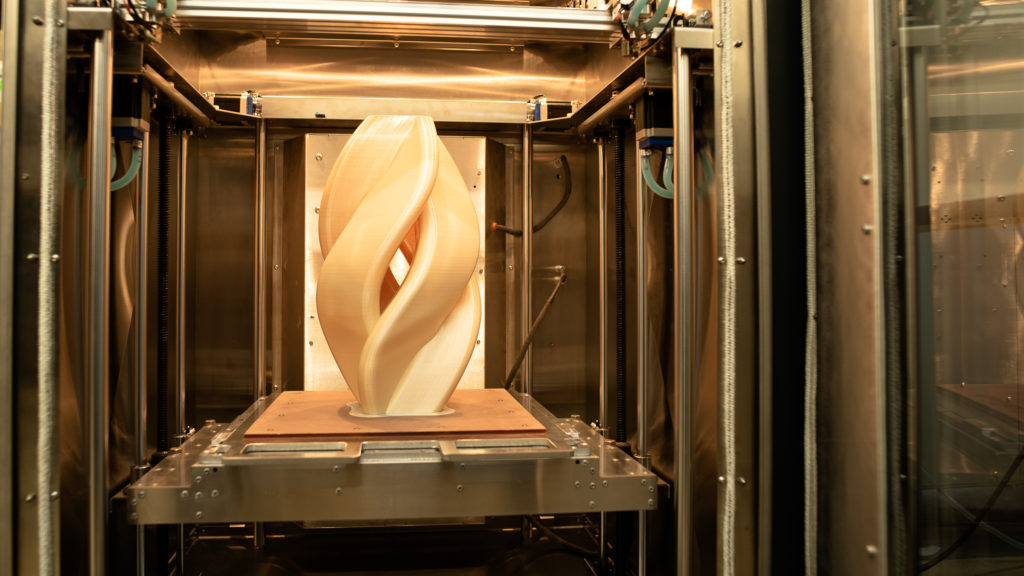

ULTEM 9085 with AMS31F support filament – images: AON3D

ULTEM 9085 Part in the AON-M2 2020 Industrial 3D Printer

At the design level, “users bring the design element to the table, and it’s the OEM’s job to deliver on the rest. Users want the freedom to choose the right material for the job, at competitive prices, and without the need to undertake additional R&D. From Day 1 we have been committed to the idea of enabling an open material ecosystem through a combination of partnerships with material suppliers, a business model that doesn’t financially punish customers as they scale, and a technical service offering that eliminates the challenges associated with developing the process parameters for new materials”, continues AON3D’s CEO.

If Kevin Han confirms the importance of partnerships with material suppliers, Charles Han leys emphasis on a point that also seems trivial: the importance to improve the overall engineering mindset. After all, we can have the perfect combination behind a partnership, but in the end, the engineers working behind will constitute the performance indicator of the company’s scalability.

“The overall engineering mindset can also be improved, as well as the engineering concepts that can be optimized to adapt to the characteristics of 3D printing. Based on our experience, we also found out that many raw data files generated by traditional engineering methods can deliver unexpected results if printed directly in FDM without any changes made. However, the printing performance can be improved by changing the internal structures of 3D models without any compromise on the quality delivered”, Charles Han explains.

Nevertheless, improving the mechanical properties of a part is, as per the words of Kevin Han, both the biggest opportunity and challenge the industry faces today. If software constitutes another “Holy Grail” of the manufacturing process – too long to address in this paper -, to maximize part performance, the specialist advises to control the process.

“A block of marble and hammer & chisel in the hands of a master sculptor would yield quite a different result than in the hands of someone with less experience. Similarly, the same material and printer with optimized process parameters will yield a better part than with non-optimized process parameters”, completes the CEO of AON3D.

Current expectations regarding Industrial FDM 3D Printing

We have seen in the above lines that printing issues and part performance have enabled developments in FDM technology. Today’s market shows that this technology has the required capabilities to help manufacturers achieve several applications.

However, moving forward, the question of scaling up a business using FDM 3D Printing remains important. Fulfilling this dream of FDM additive manufacturing for production might require the use of a fleet of 3D printers or 3D printing farms.

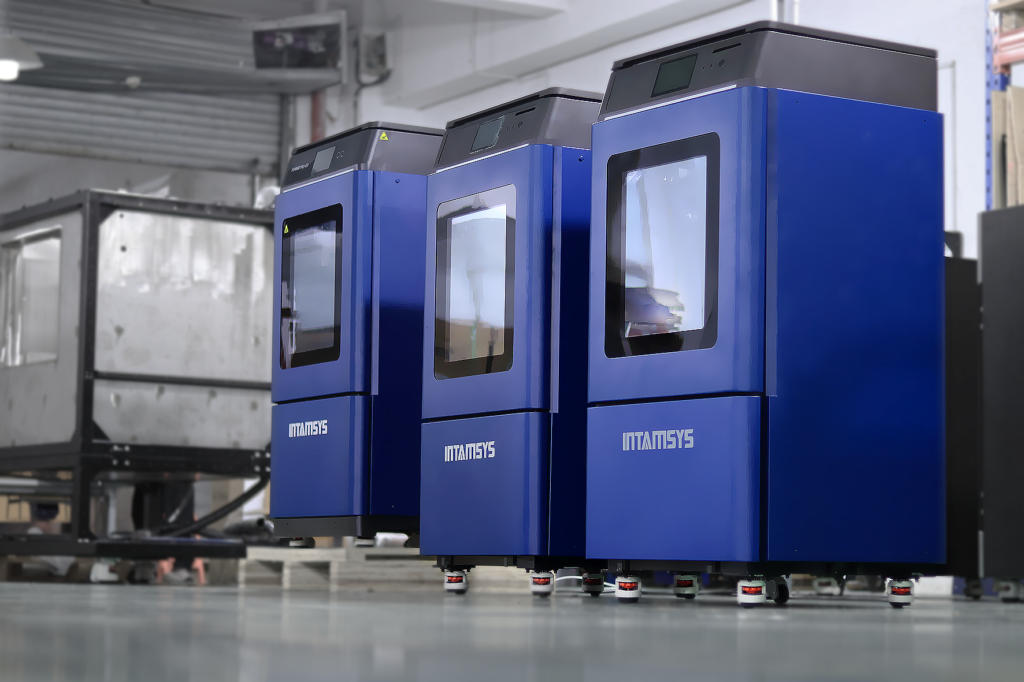

“Depending on the application and the workload, some companies may want to use 3D printers for functional prototyping, in this case, a few 3D printers are enough. Some companies may have a lot of tooling applications in their factory; thus, they may need a larger number of 3D printers. There are also a lot of companies willing to use 3D printing for low volume production. These companies might want to build proper 3D printing factories with a significant number of 3D printers”, Charles Han concludes.

The approach to additive manufacturing and 3D printer construction is changing and decades after its creation, FDM is today, legitimately positioned to open up new markets for extrusion-based systems.

This dossier has first been published in the March/April Issue of 3D ADEPT Mag.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com