As we are moving toward the end of this summer of extremes (floods, heat and fire), there is a warning that can’t be ignored: the catastrophic impacts of extreme weather depend at least as much on people as on climate. Even though we all know companies can leverage additive manufacturing technologies to play their part in tackling (some of) these environmental issues, it’s crucial to note they must do that by revealing tangible examples and measurable actions of their moves.

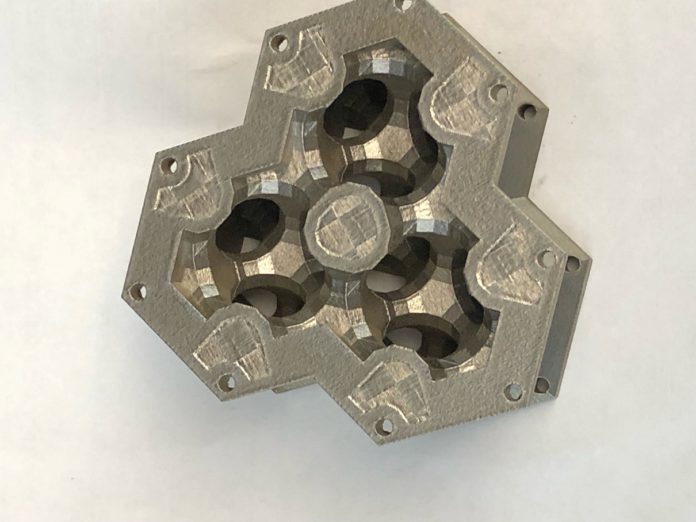

On the other hand, it should be noted that a number of promising actions to address this topic are still at an experimental stage. As a matter of fact, with the goal of extracting CO2 from the atmosphere, GE Research is working with University project partners to develop a system that will combine novel 3D-printed heat exchanger technology with innovative sorbent materials.

The same team is already working on a similar approach to extract water from air as part of the AIR2WATER project. The only thing is that, the main objective in the AIR2WATER project is to provide potable clean water for troops in the field.

“We’re combining GE’s extensive knowledge in materials, thermal management and 3D printing technologies with UC Berkeley’s world-class expertise in sorbent materials development and the University of South Alabama’s and sorption modeling and testing to design a novel system for removing carbon dioxide from the air,” said David Moore, the Principal Investigator and Technology Manager for Material Physics and Chemistry at GE Research. “Through this project, we’re aiming to demonstrate the feasibility of a system that could become a future large-scale, economical solution for widespread decarbonization of the energy sector.”

Professor of Chemistry, Omar Yaghi, who will lead the team from UC Berkeley explains that since the first crystallization and proof of porosity of metal-organic frameworks in 1995 and 1998, respectively, they have been continually developing their chemistry and design on the atomic/molecular scale.

“Teaming with GE on applying these materials in carbon dioxide capture is therefore a timely and most fortunate collaboration to address one of the most pressing problems facing our planet”, he notes.

On the University of South Alabama’s side, Prof. Grant Glover, will help inform the selection of the right materials for the system. He will rely on Metal Organic Frameworks (MOFs) to design materials to separate gases.

The team has been awarded a two- year, $2 million project through the U.S. Department of Energy (DOE) to develop this novel system.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com