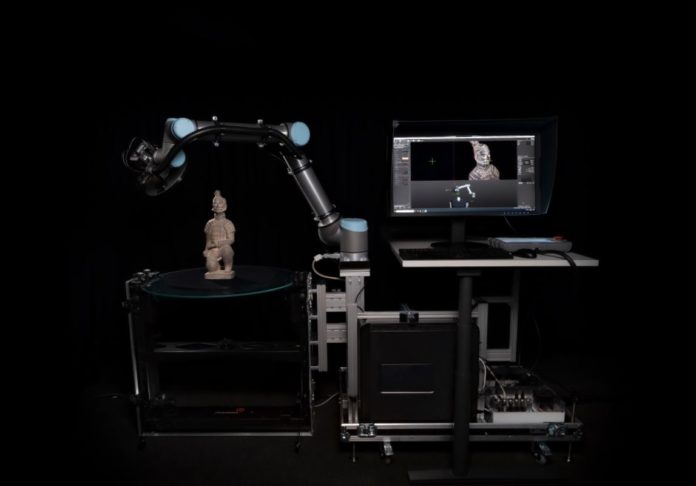

With the goal of enabling museums to digitize their collections, Darmstadt-based Fraunhofer IGD has developed an automated robotic arm 3D scanning technology to 3D scan cultural objects.

Fraunhofer IGD is an institute for applied research in visual computing- computer science based on images and 3D models. Some of the developments of the company for the 3D printing industry include Cuttlefish, a universal 3D printer driver that we saw in application Laika’s film “Missing Link”.

The 3D Scanning solution we are talking about today is named CultArm3D – It is a mobile device that delivers precise 3D models of exhibits of various sizes at the push of a button. The robotic arm is the result of the cooperation between the German research institute and the Danish camera manufacturer Phase One.

The camera manufacturer equipped the 3D scanning with an iXG 100-megapixel camera to facilitate the development of ring lights for optimal illumination. This is important because the virtual models must be good enough for scientists to analyze them as they see fit and compare them to models of other objects, which fragile originals would only permit or be able to withstand under certain circumstances.

The developers at Fraunhofer IGD paid special attention to objects with challenging surface geometries, such as shiny or reflective objects made of gold or bronze with complex occlusions. All established standards and international recommendations were followed with regard to not only system calibration (based on ISO/TS 19264 and VDI/VDE 2634) but also object metadata and digital model data (based on Europeana Data Model, 3D Task Force and CARARE), which ensures reproducible high quality in terms of geometry, textures, and color a first on the market.

How does it work?

The scanning arm is easy to operate and can be done by museum staff without supervision. The built-in software guides the user through a quick calibration process during initial setup that only needs to be done one time when the system is first started. The only thing to do then is to place the objects in the middle of the included rotary table and press a button to start scanning everything else is fully automated.

Operators should not worry about valuable exhibits as the design includes various safety precautions proven in the industry for protecting the objects being scanned. One example is a feature that automatically locks the joints of the scanning arm in place in the event of a power failure.

A quick preliminary scan establishes a basic grasp of the size and shape of the object. Dynamic viewpoint selection during scanning ensures that every detail of the object visible to the sensor is captured in true color and with optimal definition in the fewest number of images. Even challenging, reflective materials and complex geometric occlusions on the surface are captured. For reflective surfaces, this eliminates the need to use a mattifying spray to capture their geometry. For complex object geometries, manual postprocessing of the 3D models is minimized or usually completely eliminated. The dynamic viewpoint selection continues until the user-defined quality targets for minimal coverage and resolution are achieved. The final 3D model can then be output in various formats, such as in high-resolution 2D or 3D video, as a 3D web model, for virtual and augmented reality presentations, or as a print file for a 3D printer. All established standard 3D formats and many other output formats are supported.

There are two models of the CultArm3D for objects up to a meter tall and weighing up to 60 kg. Larger scan volumes and weights can be supported on request. The scanning arm is mobile, and its light weight makes it easy to transport. When on site, all it needs is a regular power supply, allowing it to scan collections at various locations.

First applications

First users of Fraunhofer’s new solution include the State Museum of Baden in Karlsruhe, the Thuringian University and State Library at Friedrich Schiller University Jena and, soon, the University and State Library Darmstadt.

In Karlsruhe, the Fraunhofer IGD scanner has been integrated into the visitor concept, allowing guests to scan museum objects in 3D under supervision and then see the results of their work for themselves on interactive touch tables or with VR glasses.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com