Forward AM Technologies which recently became a standalone company focuses on sustainable solutions in the 3D printing industry.

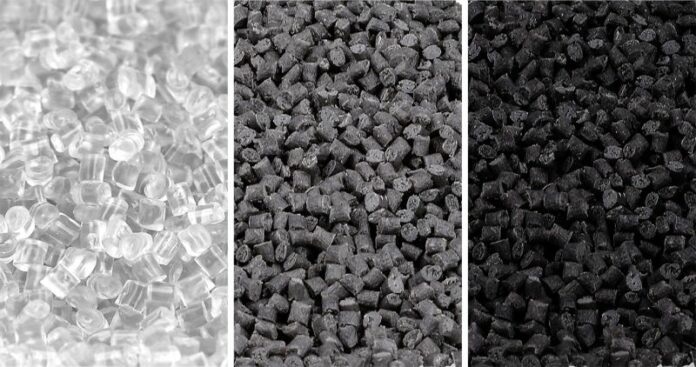

It has launched a series of Ultrafuse® Pellets to enhance large-scale 3D printing or Large Scale Additive Manufacturing (LSAM). These pellets can be used for safety-critical, industrial, automotive, and architectural applications.

They are ideal for most extruder systems (industrial or desktop 3D printing). The Ultrafuse® Pellets from Forward AM Technologies can be used for molds, tools, jigs, and fixtures. Other applications include food containers, medical equipment, electronic covers, functional prototypes, and welding parts.

Features of Ultrafuse® Pellets

- Deliver enhanced strength and stiffness

- Enhanced UV stabilization

- High heat resistance

- Low density

- Low moisture uptake

- Outstanding, detailed, and homogenous surface quality

- No compromise on speed or warpage

- Offer high-gloss finish that is required for superior optical appearance

- Excellent chemical resistance

BASF’s Ultrafuse® Pellets are made from recycled materials. The unique recycling process makes them safe for food contact. This can go a long way in making the 3D manufacturing methods more sustainable.

These micro pellets are made with high-performance PP (polypropylene) and 30% glass fibers. They combine superior surface quality and transparency with excellent mechanical properties. Other benefits of Ultrafuse® Pellets include batch-to-batch stability and pre-dried processing.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.