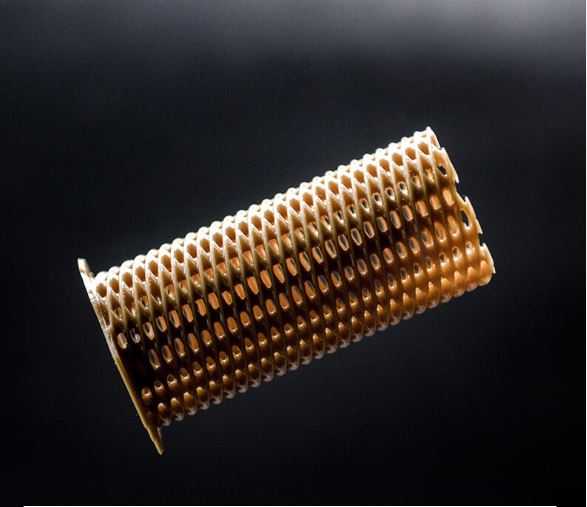

As a reminder, the Boston-based manufacturer utilizes the Digital Composite Manufacturing (DCM) to produce the strongest resin possible. As par of this partnership, the manufacturer will combine this expertise to DSM’s application knowledge in 3D Printing resin and formulation development.

Already known for its expertise in filaments, this collaboration will also enable Fortify to benefit from DSM’s mature supply chain and years of experience developing advanced materials.

New opportunities for other resins

The reality shows that 3D printing systems are often limited in their use because of the number of materials they can process. Indeed, companies do not often open up their technology to materials that they do not produce. Even though they try to reverse the situation today, a certain gap still remains, between 3D Printing platforms and the variety of materials they can process.

“We don’t want to limit our customers’ ability for growth and exploration within additive,” explained Karlo Delos Reyes, VP of Business Development at Fortify. “We guarantee our customers flexibility by embracing open innovation.”

In this case, partners can properly harness the power of composites without having to build out the in-house expertise that Fortify provides.

At the technical level, we will see structural parts that integrate strong mechanical and temperature properties. Rapid tooling, jigs and fixtures are a few examples of applications that can be achieved at the end of this collaboration.

Moreover, Fortify and the DCM platform will become a distribution channel for DSM’s 3D printing materials.

This announcement is another example of how partnerships between various players of the industry will unlock many barriers faced by professionals in the industry.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com