Two critical factors drive efficiency in manufacturing: production throughput and workflow integration. Yet, these elements are often evaluated in isolation. While that approach may seem practical, it overlooks the interconnected nature of additive manufacturing (AM). AM is inherently holistic—what matters to one user or application might not apply to another. A careful evaluation of Thermwood’s LSAM system reveals it delivers on both fronts. The article below explores how and why.

In an AM context, production throughput refers to the rate at which 3D printed parts are produced, while workflow integration consists in evaluating how well different steps of the production process are connected and coordinated. This means checking whether processes flow smoothly from one stage to the next, whether software and tools are working together effectively, and whether the overall system is streamlined.

What are the criteria for assessing a production throughput?

Very often, the performance of a 3D printer is limited to the maximum mechanical speed (build speed) it can deliver. This makes sense since throughput refers to the number of parts a system can produce in a given time frame.

This important metric should be assessed along with other key metrics such as machine utilization, yield rate, capacity planning, and material throughput.

In general, industry benchmarks for Large Format Additive Manufacturing (LFAM) are still evolving. While this article will share a few examples of comparison with other LFAM solutions, the analysis below is mainly based on several applications enabled by Thermwood’s LSAM covered by 3D Adept Media, peer-reviewed literature, and an interview with Scott Vaal, Thermwood’s LSAM product manager.

Key assessment of Thermwood’s LSAM system

We’ll have a closer look at deposition rates, batch production, and machine utilization for this specific analysis.

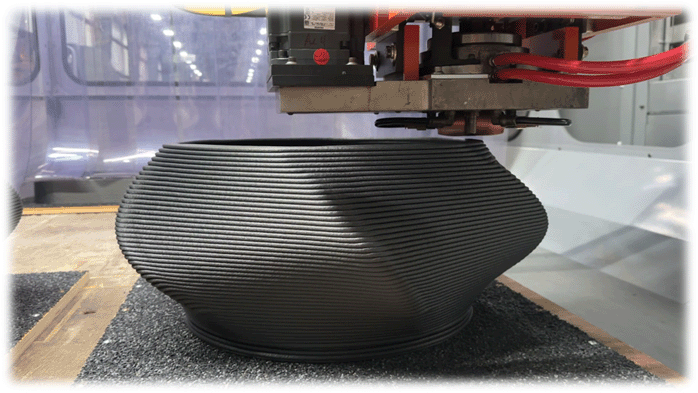

Deposition rates

Traditional LFAM systems achieve deposition rates exceeding 2 kg/hour, with some systems reaching up to 100 kg/hour using thermoplastic pellets.

Traditional LFAM systems achieve deposition rates exceeding 2 kg/hour, with some systems reaching up to 100 kg/hour using thermoplastic pellets.

According to Scott Vaal, “Thermwood’s LSAM systems are among the fastest in the LFAM (Large Format Additive Manufacturing) space. Print rates can exceed 500 pounds per hour, depending on the material and part geometry. Compared to traditional manufacturing methods, LSAM dramatically reduces lead times for large, complex parts—often from weeks to days. It also outpaces many other LFAM systems due to its high-output print heads and superior slicing software.”

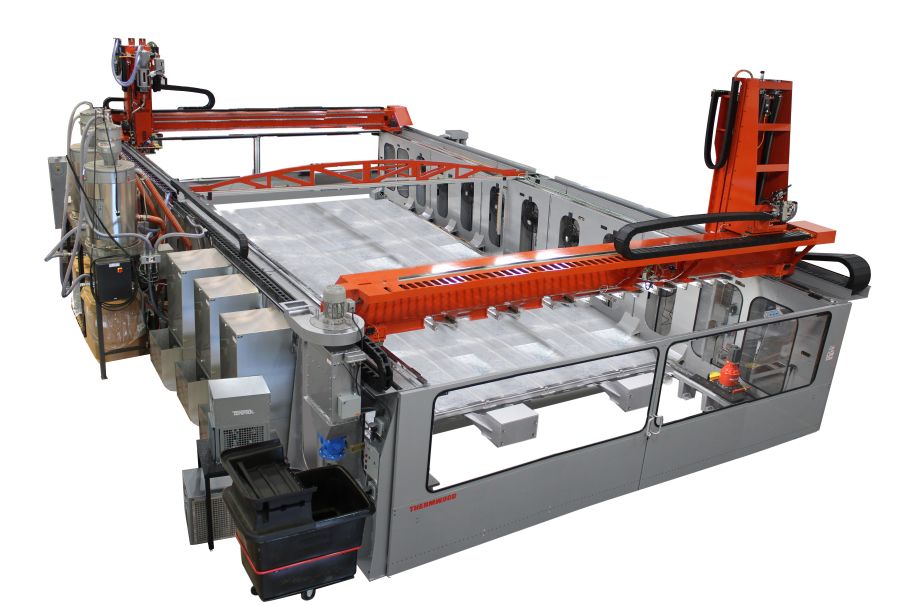

LFAM printers typically offer build volumes greater than 1 cubic meter, with some systems capable of producing parts up to 2.5 meters in height. Thermwood’s various configurations of LSAM systems play to the company’s strength here. The largest LSAM system from the company offers a build envelope of 15 feet wide by 40 feet long. The company also includes in its portfolio a Vertical Layer Printing (VLP) system that enables parts to be printed vertically. This system can produce parts up to 15 feet wide and as tall as the length of the table, depending on the specific configuration.

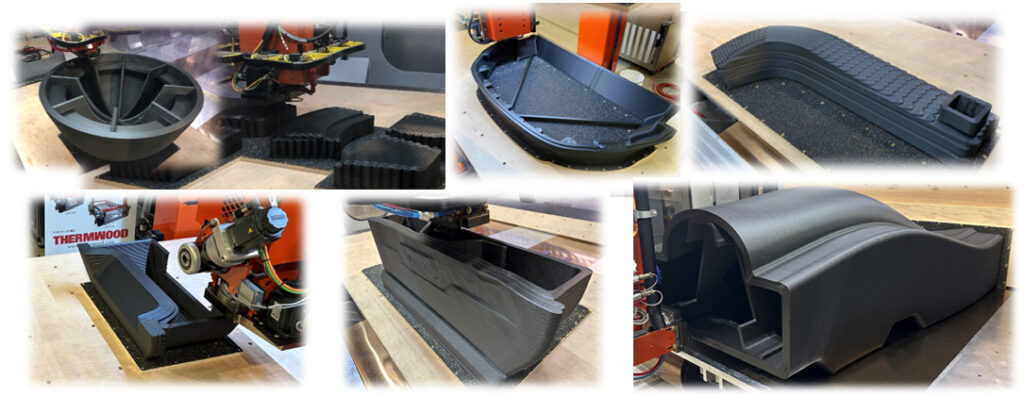

Batch production

LFAM in general is not usually associated with batch production. Those systems typically produce directly large complex parts or tooling rather than high volumes of small parts. interestingly, in the market of LFAM for metal parts, it’s possible to see a few technologies suited for batch production of metal components in aerospace or energy sectors.

In the thermoplastic field, Scott confirms that “while LFAM is typically associated with custom or low-volume production, Thermwood’s LSAM systems are capable of batch production, especially with repeatable tooling, molds, or fixtures. LSAM can also speed up production by printing multiple different tools at the same time.”

Machine utilization

At this level, it’s interesting to look at the machine uptime, maintenance, and reliability factors. The truth is, many LFAM systems often experience frequent downtime due to material handling complexities, print head wear, or calibration needs. It’s worth mentioning that reliability often depends on the differences in extrusion methods or less mature automation, which can lead to increased operator intervention and maintenance frequency.

Thermwood’s use of pellet-fed extrusion and integrated CNC trimming helps minimize interruptions. Its modular print heads and software diagnostics allow for easier preventive maintenance and quicker issue resolution.

“LSAM incorporates predictive maintenance features and remote diagnostics. Maintenance is streamlined with accessible components and comprehensive support. Real-world uptime is high, especially with routine preventive maintenance, and reliability is enhanced through redundant safety systems, closed-loop temperature controls, and robust machine construction,” Vaal states.

“LSAM incorporates predictive maintenance features and remote diagnostics. Maintenance is streamlined with accessible components and comprehensive support. Real-world uptime is high, especially with routine preventive maintenance, and reliability is enhanced through redundant safety systems, closed-loop temperature controls, and robust machine construction,” Vaal states.

What about workflow integration?

I have always found the ability to combine large-scale 3D printing with CNC trimming a huge win for Thermwood as it removes manual repositioning and reduces post-processing time. It turns out that this is the basic benefit one can expect from any hybrid manufacturing system.

What’s interesting to assess today is the design and simulation tools supporting the system’s integration and, most importantly, how well it can integrate into existing production workflows.

As far as design and simulation tools are concerned, Vaal confirms here that the company’s systems are compatible with CAD (it can handle models from virtually any CAD/CAM system), and that the LSAM Print3D software handles slicing with patented capabilities for variable bead width, layer height control, and custom print strategies.

“LSAM Print 3D software can backplot, simulate print paths, and create a 3D Print simulation of the printed beads. It can give you material usage required and accurate print time estimates. Our print files and LSAM machines can also be simulated using industry-leading direct code simulation software. LSAM also utilizes Additive 3D software via the LSAM Research Laboratory and Purdue University’s Composite Manufacturing and Simulation Center. This software provides the ability to create “First Time Right Printing” by simulating material behavior, stress/strain, and thermal distortion,” he explains regarding simulation.

As for the integration into existing production workflows, “LFAM systems, such as Thermwood’s LSAM series, are designed to plug directly into modern manufacturing environments. Our proprietary LSAM Print3D software plays a central role here. It allows users to precisely define the print path, layer thickness, and thermal control strategies before production begins, feeding directly into digital twin models. These simulations are critical for validating both printability and performance in advance, especially for complex or mission-critical parts,” he points out.

Concluding notes

According to aerospace and automotive tooling projects delivered by LSAM so far, the technology has helped deliver around 90% first-time-right builds with integrated thermal control and real-time print monitoring. The system’s CNC trim head, combined with workflow software integration, allows for automated post-processing and reduced lead times by over 60%.

“LFAM is not just a new tool—it’s a transformative manufacturing approach, and Thermwood’s LSAM system leads the charge in production-scale additive capabilities. Whether you’re producing aerospace tooling, foundry patterns, or custom structures, LSAM offers the speed, precision, and flexibility to fundamentally reshape your manufacturing workflow. As materials, automation, and software evolve, LFAM will only become more capable—and Thermwood is committed to pushing those boundaries. LFAM is no longer a future technology—it’s a present-day production tool. The future of LFAM is not just about building bigger parts—it’s about building smarter systems,” Vaal concludes.

Ultimately, what’s important to keep in mind is that a production throughput and workflow integration can be considered good when quantifiable performance metrics align with production goals, and the system runs efficiently within an integrated, end-to-end workflow.

This content has been created in collaboration with Thermwood. Read more news on Thermwood.

Disclaimer:

To ensure a fair and focused discussion, other technologies are not named or compared directly in this article.