Home =

laser powder bed fusion - search results

If you're not happy with the results, please do another search

Advance Laser Materials to distribute four 3D printing materials from BASF

Advanced Laser Materials (ALM) and BASF 3D Printing Solutions, have signed a distribution agreement for four new Forward AM by BASF powder solutions.

ALM is an EOS company that develops materials for industrial 3D printing....

U.S. Air Force utilizes AM Software Senvol ML to qualify a multi-laser additive manufacturing system

U.S. Air Force utilizes AM Software Senvol ML to develop methodology for multi-laser additive manufacturing program

U.S. Air Force is currently leading a collaboration between Air Force Research Laboratory (AFRL) and Air Force Life Cycle...

Wayland Additive explains NeuBeam, a brand-new alternative to traditional laser PBF and eBeam PBF

There is so much to discover about metal additive manufacturing, that year on year, several investments continue to be made in R&D activities across all key industrial sectors. The truth is, the more companies...

ENGIE received certification for its additive manufacturing (AM) facility and powder laboratory

As Additive Manufacturing is gaining momentum, it is of paramount importance for operators to comply not only with materials and hardware standards but also with facility safety.In this vein, ENGIE Laborelec and ENGIE Fabricom,...

Issues raised by metal powder removal

With contributions from EOS, SOLUKON & RÖSLER

Post-production, somehow, is the part of the manufacturing process that intimidates professionals most. The industry shows a certain lack of skills and control throughout the entire production chain...

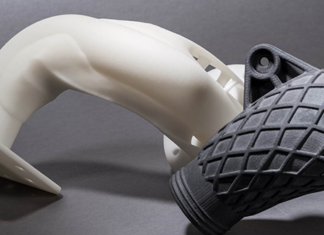

Multi Jet Fusion vs. Selective Laser Sintering

Multi-jet Fusion and Selective Laser Sintering are two of the most commonly used 3D printing processes around, but if you are considering employing one of these for your fabrication, rapid prototyping, or production runs, which is the best? Well, a lot of that depends upon your circumstances, so let’s consider these two processes, and their pros and cons.

Velo3D and Praxair to develop metal AM powders for the aerospace industry

The qualification of powders enables their use for a specific technology within given sectors of the industry. Velo3D, the manufacturer of the Sapphire system, has found in Praxair Surface Technologies, the ideal partner to...

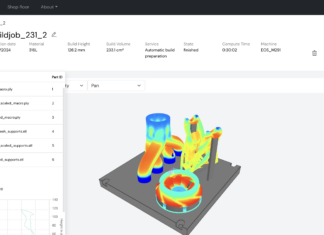

1000 Kelvin introduces AMAIZE 2.0 AI co-pilot for metal 3D printing

One year ago, software company 1000 Kelvin launched its software AMAIZE at Formnext 2023. After a year marked by several partnerships to transform 3D printing into a streamlined, automated, and intelligent process, the company...

3D4MEC & Fraunhofer IAPT to develop an advanced in-situ optical monitoring system for brass 3D printing

3D4MEC known for its Metal Additive Manufacturing services has collaborated with the Fraunhofer Research Institution for Additive Manufacturing Technologies (IAPT), to develop an advanced in-situ optical monitoring system for the 3D4BRASS printer.

Thetascan GmbH has...

Sandvik unveils a hot-work tool steel for both AM and conventional manufacturing processes

Known for its metal powders & Additive Manufacturing solutions, Sandvik has launched Osprey® HWTS 50, a hot-work tool steel powder with improved printability. Designed for laser-based Additive Manufacturing, it can also be used with...