Home =

ORNL - search results

If you're not happy with the results, please do another search

Ornl And Utoledo Agree To carry out a Research on Lightweight Advanced Materials For Automotive

The U.S. Department of Energy's Oak Ridge National Laboratory and The University of Toledo have entered into a memorandum of understanding for collaborative research into the advanced design and manufacturing of high-strength, intelligent, lightweight...

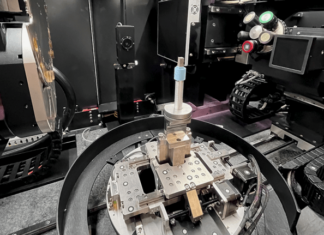

ExOne Licenses ORNL Ceramic Metal 3D Printing to produce neutron imaging parts

Specialist of binder jetting technology ExOne has licensed a patent-pending method of 3D printing a ceramic-metal material from the Oak Ridge National Laboratory (ORNL).

Both companies had previously announced their collaboration to develop cutting-edge technology...

GKN Aerospace: ORNL’s agreement and first flight of GKN’s OID technology involving 3D printed components

GKN Aerospace just signed a five-year research agreement for $17.8 million with Oak Ridge National Laboratory (ORNL).

Both parties will make use of ORNL’s Manufacturing Demonstration Facility (MDF) to develop research on the industrialization...

A new software algorithm helps to reduce inspection time for 3D printed nuclear parts by 85%

While inspection time for 3D parts may vary from one application to another, experts estimate that it can take around 25% of the total production time. That’s why, the more complex inspection processes are,...

Additive Talks: The use of AM in the nuclear industry and its hidden complexities

This third episode of Additive Talks was the continuation of a conversation that started two years ago during season two of Additive Talks. With different characters this time, this virtual table provides an update...

Additive Talks: The use of AM in the nuclear industry and its hidden complexities

Two years ago, when we first sat down with industry insiders from Oak Ridge National Laboratory and Burloak Technologies to discuss the use of Additive Manufacturing in the nuclear industry (Additive Talks, season 2,...

NASA builds 3D printed rover wheel prototype for future space exploration

The Oak Ridge National Laboratory which comes under the US Department of Energy took Additive Manufacturing to the next level by 3D printing the same kind of wheel as used by NASA for its...

Xerox sells Elem Additive Solutions business to ADDiTEC

Just like we saw Local Motors rise in a certain way from its ashes, Xerox 3D printing business resurrects through an acquisition of ADDiTEC. While the financial terms around this transaction are undisclosed, the...

Additive Talks: How does Additive Manufacturing serve Electrification?

The second episode of the year of Additive Talks was dedicated to Additive Manufacturing & Electrification. The topic is discussed in a context where the adoption of AM is most of the time highlighted...

Additive Talks: How does Additive Manufacturing serve Electrification?

In simple words, electrification is the process of powering by electricity and, in many contexts, the introduction of such power by changing over from an earlier power source. As the world’s energy diet is...