Home =

ORNL - search results

If you're not happy with the results, please do another search

ORNL 3D prints “the lightest crack-free alloy” for ultrahot gas turbines

Researchers from Oak Ridge National Laboratory (ORNL) and the National Energy Technology Laboratory have 3D-printed a crack-free alloy that can operate without melting at temperatures over 2400°F (1315.5°C).

This latest achievement from ORNL could enable...

JuggerBot 3D partners with ORNL & MSU for the AFRL Additive Manufacturing project

Industrial 3D printer OEM JuggerBot 3D announces that Oak Ridge National Laboratory (ORNL) and Mississippi State University's Advanced Composites Institute (ACI) will bring their expertise as technical partners to a hybrid Additive Manufacturing (AM)...

ORNL releases 3D printing datasets that can be used to enhance the quality of 3D printed parts

The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The...

ORNL researchers 3D print defect-free tungsten parts

Remember when I told you that tungsten’s hardness and extremely high melting point have always made it difficult to process via additive manufacturing technologies? Add to that the fact that the development of defects...

3D printing large rotating steam turbine blades for generating energy in power plants – ORNL just ticked this box

Researchers at the Department of Energy’s Oak Ridge National Laboratory recently achieved the production of large rotating steam turbine blades for generating energy in power plants.

Led by partner Siemens Technology, the U.S. research and...

Lithoz and ORNL to assess the LIS technology capabilities for 3D printed non-oxide ceramics

How can one ensure the fabrication of non-oxide ceramics with high-refractive indexes, such as silicon carbide, for use in extreme temperature applications?

Ceramic 3D printing company Lithoz’ new partnership aims to answer this one-million-dollar question....

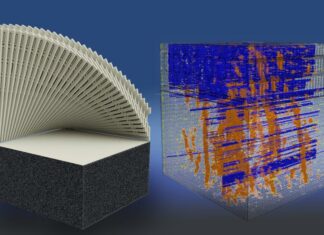

ZEISS & ORNL sign licensing agreement for inspection of 3D printed parts

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and manufacturer of multidimensional metrology solutions ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components...

IperionX and ORNL to develop low-cost titanium alloys for additive manufacturing

A lot is going on the agenda of the U.S. Department of Energy which has recently approved a collaboration between materials producer IperionX and research institute Oak Ridge National Laboratory to advance the application...

Ultra Safe Nuclear licenses ORNL method to 3D print Nuclear Reactor Components

The Department of Energy’s Oak Ridge National Laboratory has developed a new method to 3D print components for nuclear reactors.

Licensed by Ultra Safe Nuclear Corporation aka USNC, this method uses a sophisticated additive manufacturing...

ORNL equips TVA Browns Ferry nuclear plant with 3D printed nuclear reactor components

“This project provides the foundation for designing and manufacturing a variety of 3D-printed parts that will contribute to creating a clean energy future”, John Strumpell, manager of North America Fuel R&D at Framatome.

As far...